In the early 1930s, Marriner Browning, the nephew of the famous designer J.M. Browning, initiated a project based on the design of the BAR automatic rifle. The main idea was to adapt the configuration and automatic action of the BAR M1918 for belt feed. This would allow for increased capacity and sustained firing, but required the development of a complex feeding mechanism that had to operate synchronously with the gas system and the bolt. The main difficulties were associated with ensuring reliable feeding and precise chambering of the cartridge at a high rate of fire, especially in the dirty conditions typical of combat.

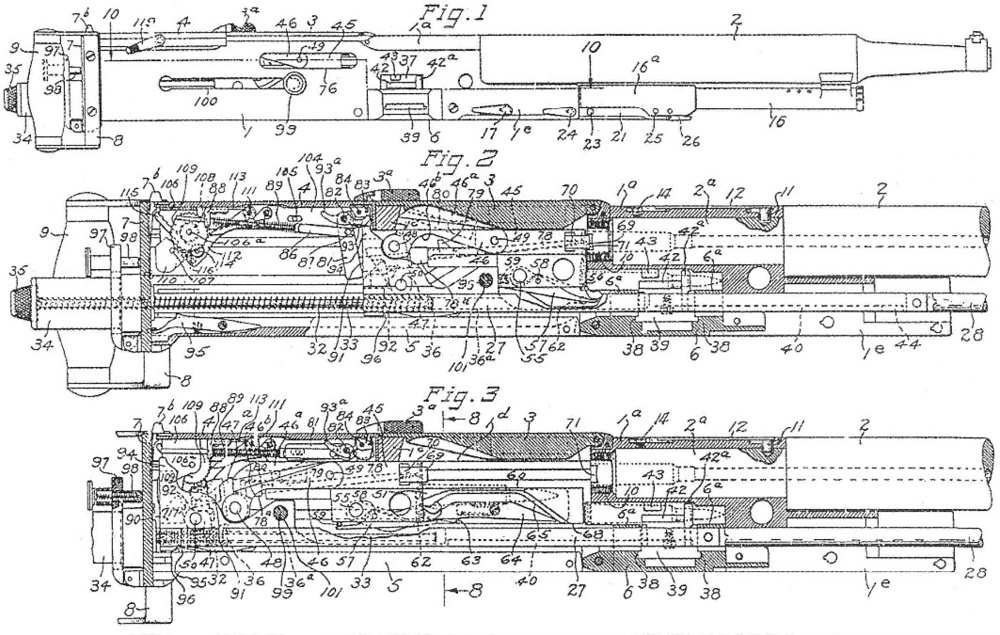

The first official demonstration of the prototype, which received the designation T10, took place at the Aberdeen Proving Ground on February 17, 1933. The presented .30 caliber sample weighed 28 pounds (12.7 kg) and was equipped with an air-cooled barrel weighing 5 kg. A key feature of the design was the implementation of the belt feed mechanism, which was actuated directly by a cam integrated into the gas piston slide. The cartridge’s trajectory was complex: it was extracted from the belt as the moving parts recoiled, then was forcibly lowered onto the chambering line and fed into the chamber from below by an extractor, similar in design to the assembly on Browning’s heavy machine guns. To ensure controllability of automatic fire, the designer incorporated a rack-and-pinion rate reducer with an anchor escapement and a double sear. The claimed reduction in the rate of fire was supposed to be from 600 to 200 rounds per minute, but actual measurements at the proving ground showed a range of 250–325 rounds per minute when the reducer was engaged. Despite a successful firing of 223 cartridges, Marriner Browning decided to temporarily suspend patenting to implement design modifications, specifically changing the location of the recoil spring.

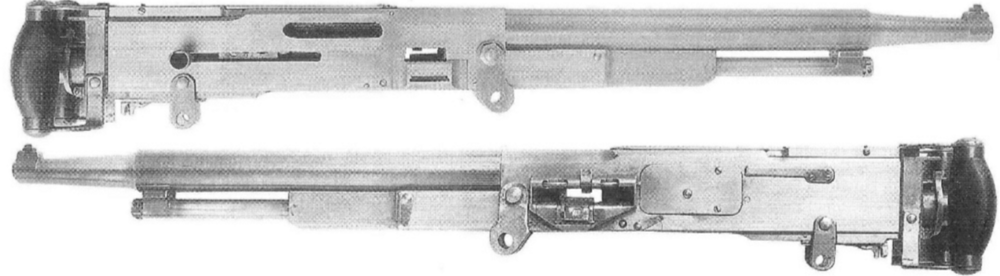

The legal formalization of the technical solutions developed by Marriner Browning during the period 1934–1937 was completed with the issuance of four consecutive U.S. patents on September 21, 1937. This documentation recorded the key features of the system’s architecture. Basic Patent No. 2,093,704 describes the adaptation of the BAR receiver for belt feed while maintaining the principle of rearward cartridge extraction, which was dictated by the dimensional constraints of the original assembly. Patent No. 2,093,705 provides for the use of a heavy barrel with transverse finning to increase heat dissipation; this solution, common in the interwar period, proved to be inefficient under conditions of heavy fouling.

Patent No. 2,093,706 regulates the design of the quick-change barrel mechanism, in which the gas piston tube functions as the locking element. The connection between the barrel and the tube is achieved via a T-shaped groove, and disassembly requires the longitudinal displacement of the tube rearward through a system of levers. Patent No. 2,093,707 describes a modified firing mechanism integrated with the rate-of-fire reducer in the stock or grip.

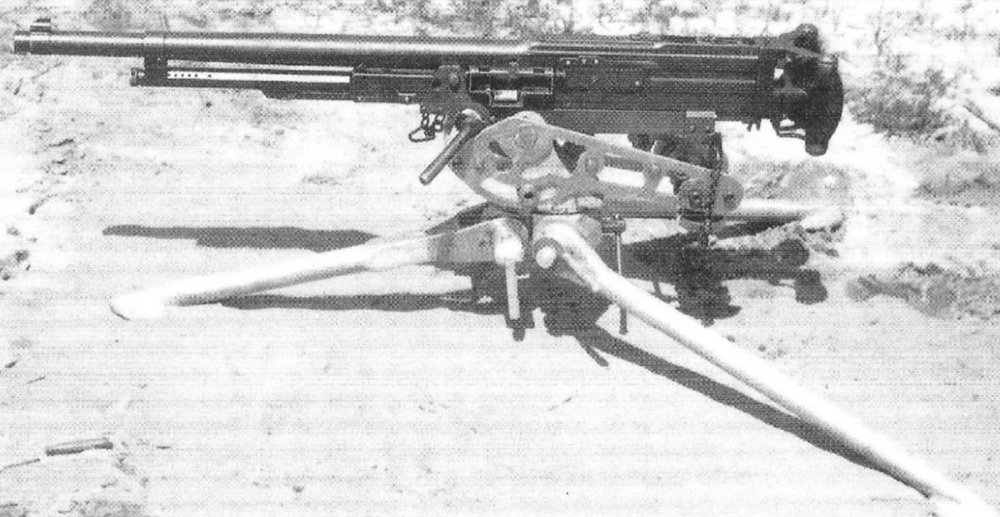

The entry of the United States into World War II highlighted the need for a light machine gun for squad-level support. On December 10, 1941, the Springfield Armory received a directive for a major modernization of the T10 model. The technical specifications required:

- Reducing the barrel weight to 2 kg.

- Replacing the buttplate with handles with a full stock.

- Installing a bipod.

- Protecting the weapon’s mechanisms from sand where possible.

- Achieving an overall weight of 10 kg.

- Adhering to a length of 96 cm.

The modified prototype, designated T10E1, underwent trials in early 1942. Despite a positive overall assessment of the weapon’s potential, critical deficiencies were identified: the insufficient kinetic energy reserve of the moving parts during forward movement made the system sensitive to fouling, the ergonomics of the stock and grip were flawed, the bipod was positioned too low, the sight (rear sight) design was unsatisfactory, the firing pin design was inadequate, and the use of an interrupted thread for barrel attachment was deemed unsatisfactory.

On March 3, 1943, the Springfield Armory presented the T10E2 modification, which addressed most of the proving ground’s recommendations, though it did not affect the firing pin. During the firing of 10,000 rounds, 124 stoppages were recorded. Furthermore, in the automatic firing mode, during which 680 rounds were fired, 9 malfunctions occurred. Overall, the test results confirmed the high operational qualities of the weapon.

The further evolution of the model under the index T10E2 faced organizational and production difficulties. The Springfield Armory, overburdened with the production of M1 Garand rifles, could not allocate resources to finalize the machine gun. An attempt to transfer the contract to the Auto-Ordnance Corporation ended in failure: the contractor presented an unsatisfactory sample, which yielded 23 stoppages per 500 rounds, and the contract was subsequently annulled. The baton was then passed to the High Standard Manufacturing Company, which developed the T10E3 variant.

Factory trials of the T10E3 prototype, manufactured by the High Standard Manufacturing Company, began on January 1, 1943, and were later continued at the Aberdeen Proving Ground. Testing revealed critical shortcomings: the inability to change the barrel when hot and problems with the upward feeding of the cartridge. In other respects, the machine gun showed good results. Subsequently, several more models were produced with various corrections, leading to improvements in the automatic mechanism and solving the problems associated with barrel change.

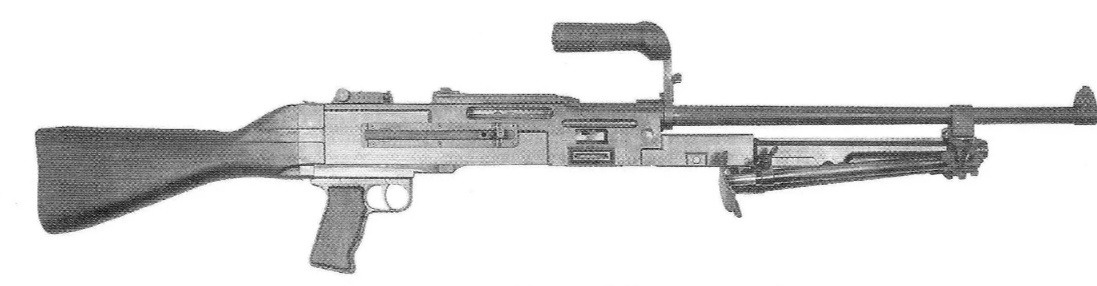

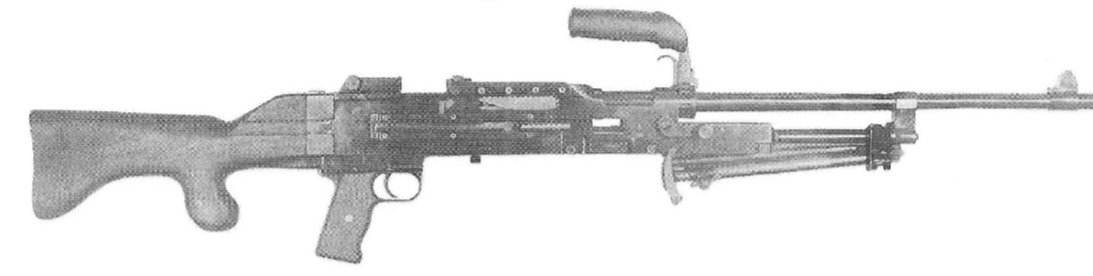

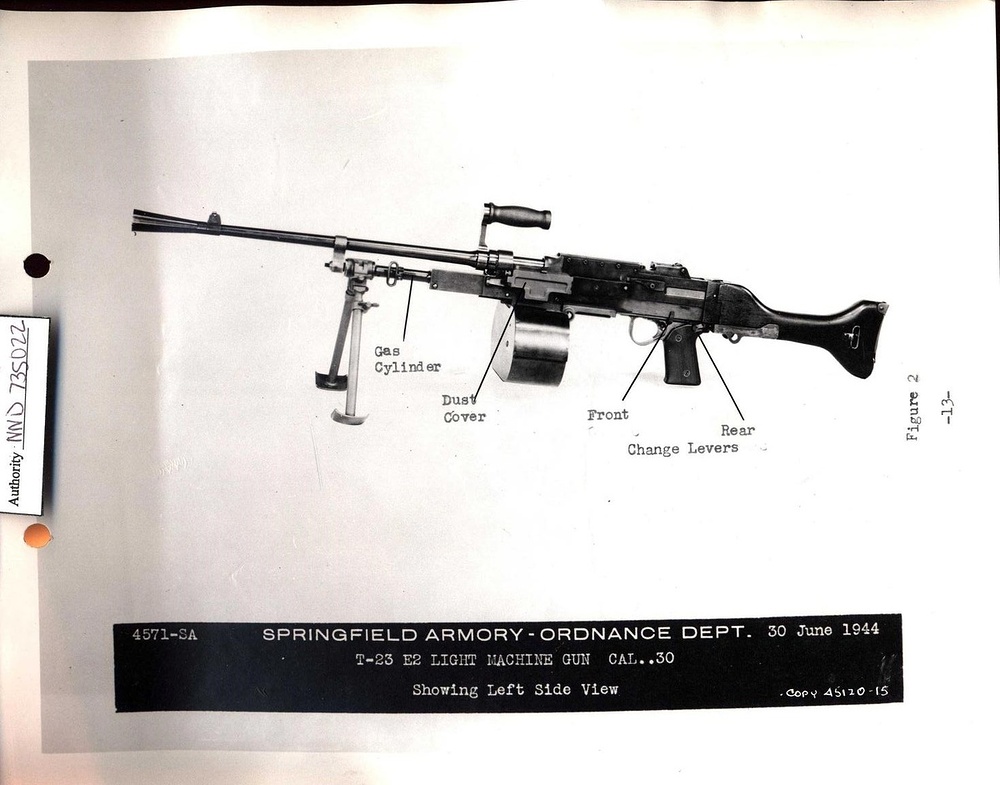

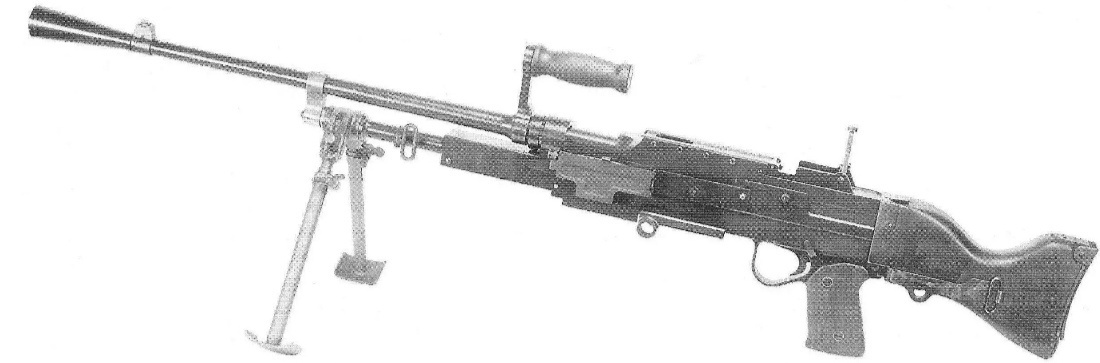

In May 1943, the Springfield Armory regained control of the project, introducing the deeply modernized T23 version. The main engineering directions of the redesign included: reinforcing and modifying the barrel lock (including integrating a locking mechanism to prevent firing when not fully locked), implementing a new rate-of-fire regulator, redesigning the fire control group (including the introduction of a spring-driven firing pin controlled by the trigger), simplifying the charging process (one working stroke of the charging handle), enhancing dust protection, and standardizing components to simplify maintenance and production.

Armory engineers attempted to solve the reliability problem by fine-tuning the gas system. A relief hole was drilled in the front wall of the gas plug to vent excess pressure, which helped stabilize the rate of fire but led to a problem with the bolt failing to reach the fully forward position. It was found that the system was extremely sensitive to tolerances: the accumulation of carbon fouling in the gas cylinder quickly led to the piston jamming.

Comparative trials of the T23E1 modification, conducted by the Infantry Board in November 1943 (Report No. 1538-A), demonstrated the weapon’s dual nature. On one hand, the 10.5 kg machine gun offered superior maneuverability compared to the standard M1919A6 and had effective dust protection. On the other hand, testing under simulated rain and liquid mud conditions ended disastrously. The complex cartridge feed path, which required the round to move in three planes inside the receiver, inevitably failed when foreign particles entered. The Infantry Board ruled out replacing the existing BAR and M1919 machine guns with the T23E1 model, although the Cavalry Board, interested in a light automatic weapon, gave it a higher rating.

The last attempt to save the project was made in the first half of 1944. Based on a memorandum from the Springfield Armory Engineering Department, numerous improvements were introduced into the design of the T23E2 modification, including, for example, the addition of a 100-round box magazine. The machine gun was tested in March 1944, and the weapon still had issues at a low rate of fire; problems operating in low temperatures were also identified.

Subsequently, the Springfield Armory carried out modifications on two T23E1 units, the key features of which were a shortened stock and the exclusion of the gas regulator from the design. The samples were submitted for testing to the Infantry Board on July 1, 1944, but demonstrated unsatisfactory operational characteristics. The cause of a number of failures recorded during the tests was the critical wear of the physical components: the T23E2 modification prototypes had previously accumulated 40,000 rounds fired at the Aberdeen Proving Ground. As a result, further development of the T23 platform was deemed impractical. The Ordnance Department concluded that the BAR architecture, originally designed for bottom-fed magazine use, had exhausted its modernization potential. The complexity of the kinematic feed scheme of “extraction-lift-chambering” made it impossible to achieve reliability comparable to captured German MG42 machine guns, which used a straight-through feed. The T23 program was definitively closed, and design resources were redirected towards creating fundamentally new systems. Nevertheless, a number of technical solutions developed on the T23, such as relocating the recoil spring to the stock, later found successful application in the Belgian FN MAG machine gun, which became a global standard for general-purpose machine guns.

- Yes

- No

- Tech Tree

- Event — separate weapon

- Event — squad with weapon

- Battle Pass

- Premium