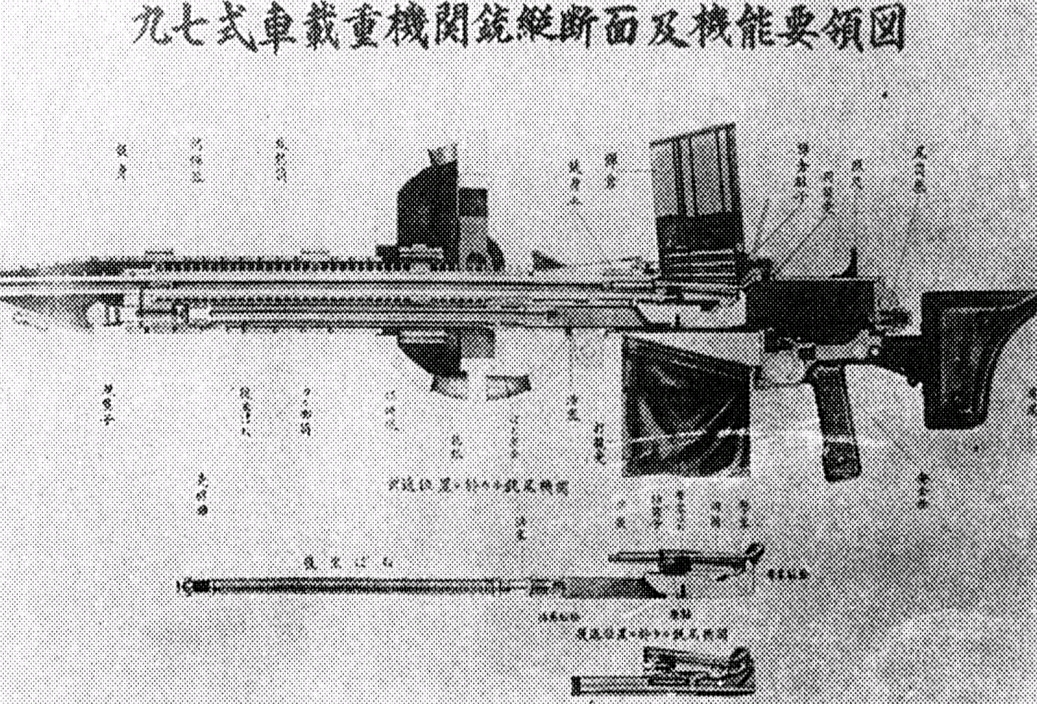

LIGHT MACHINE GUNS

LIGHT MACHINE GUNS

Development of the Type 11

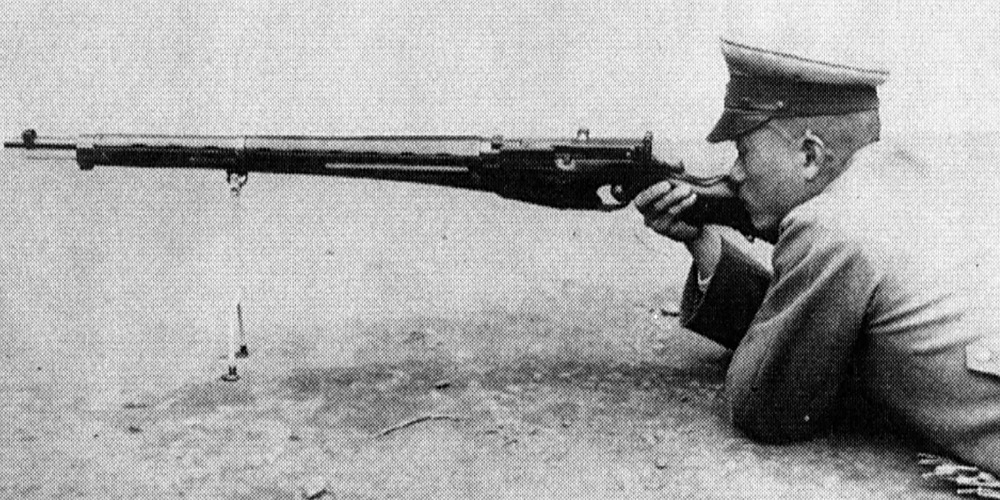

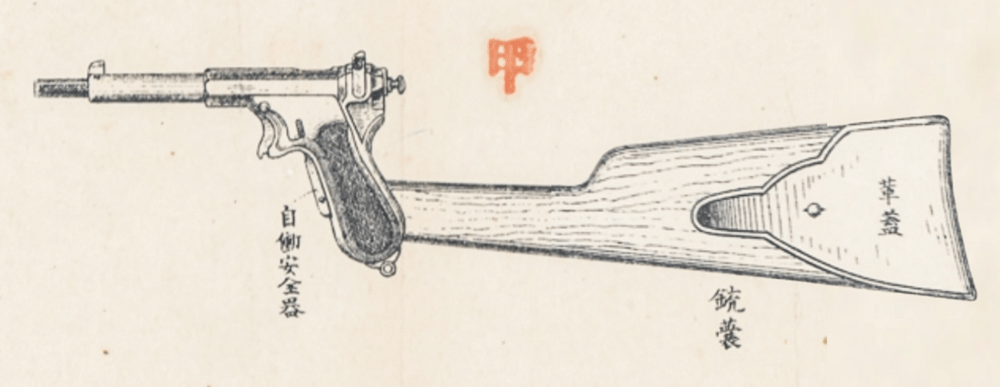

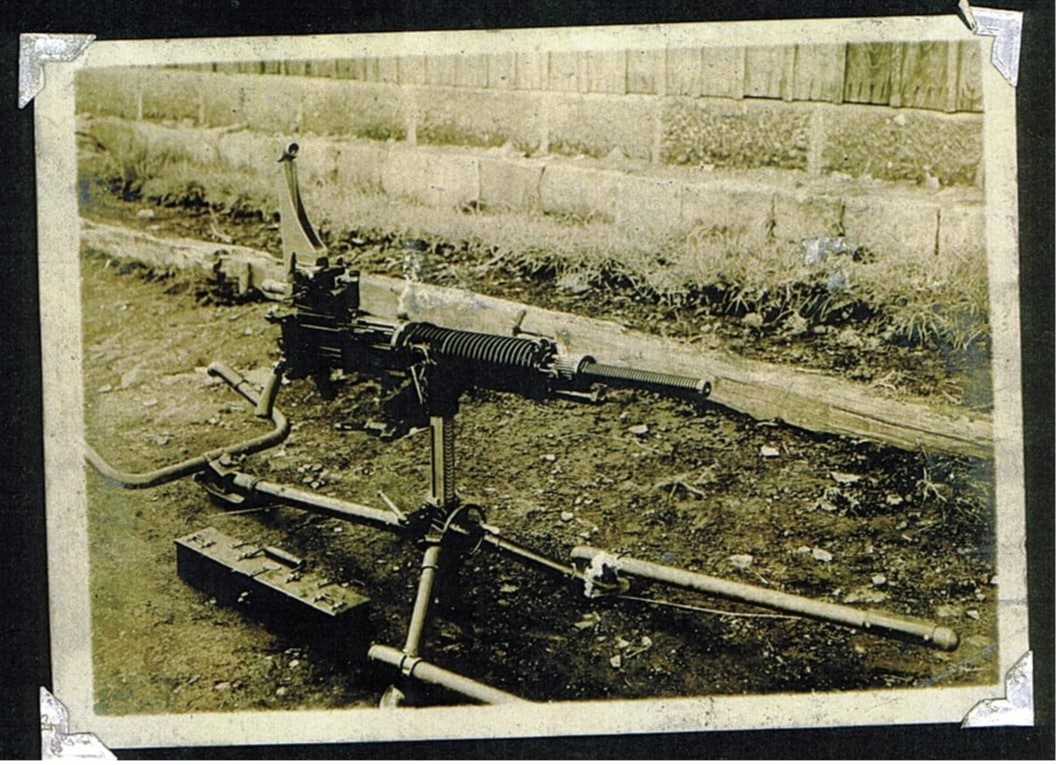

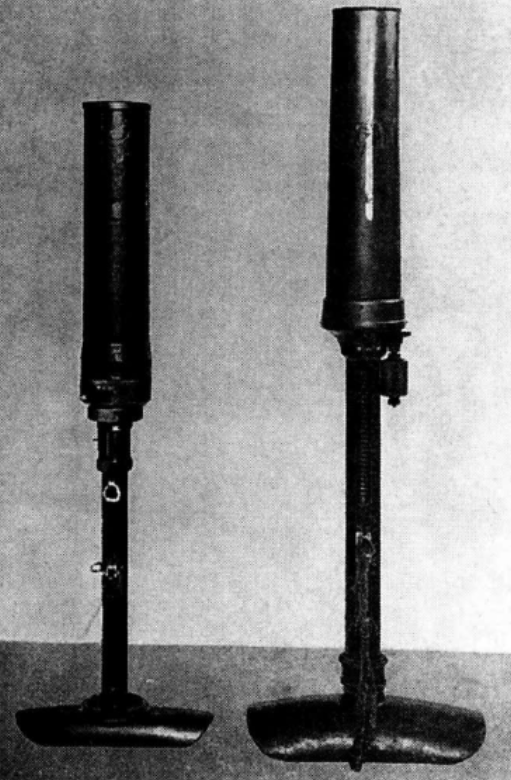

The history of Japanese light machine guns began in 1905 with the capture of a Danish Madsen from Russian forces during the Russo-Japanese War. This trophy served as a catalyst for Captain Kijiro Nambu, who, after studying the weapon at the Army Ministry, foresaw the vital role of light automatic systems in future conflicts. His early development efforts led to the 1908 Model Ko and Otsu prototypes. These designs, heavily based on the Type 38 heavy machine gun, suffered from severe reliability issues; during trials, the Model Otsu completely broke down after only 210 rounds due to frequent misfires and pierced primers.

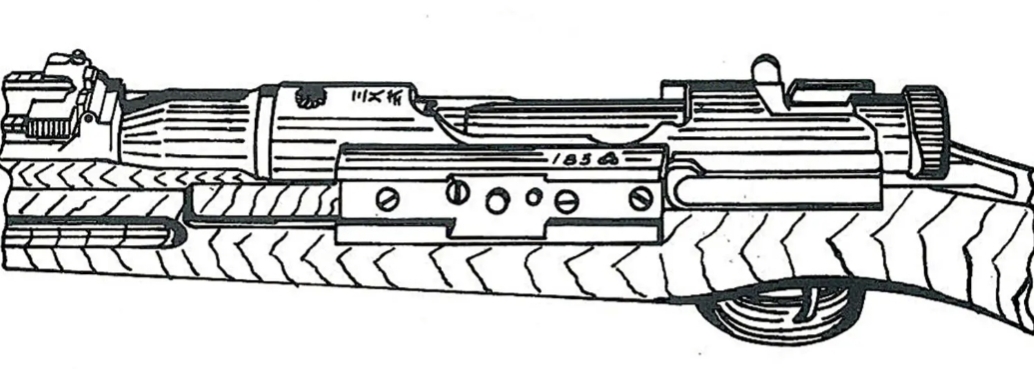

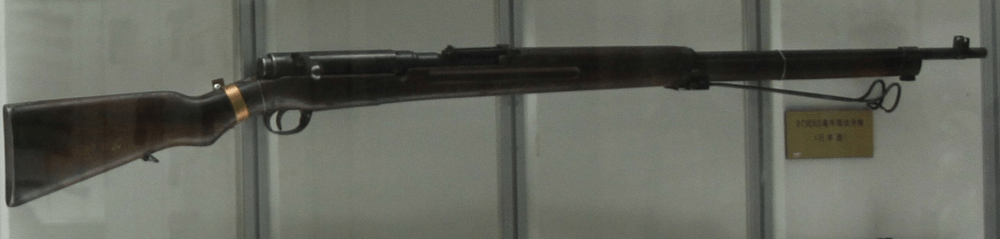

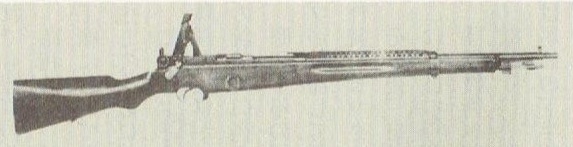

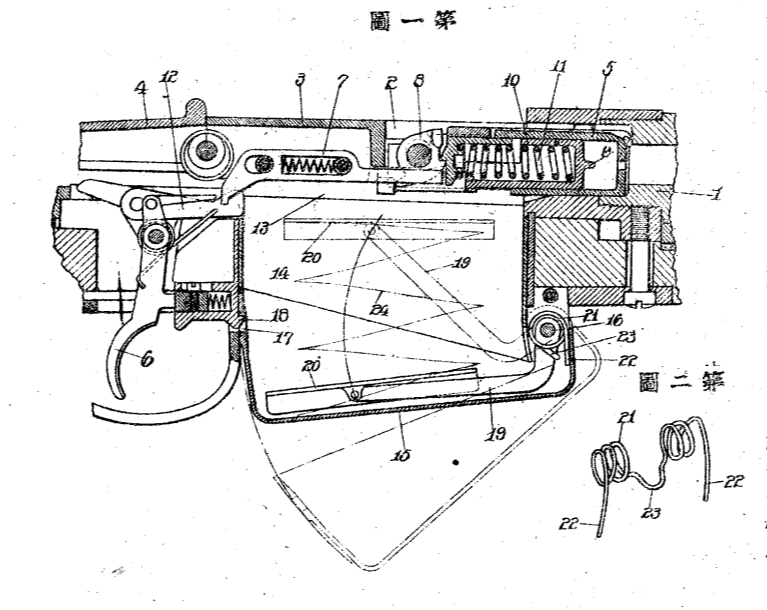

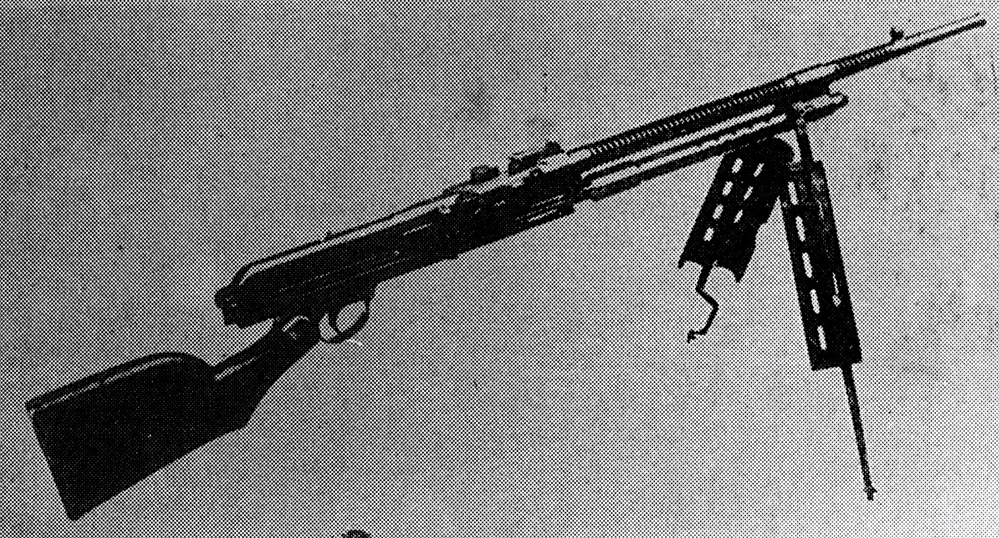

A Japanese light machine gun based on the Type 38 heavy machine gun. It was not possible to identify the specific model (Ko or Otsu).

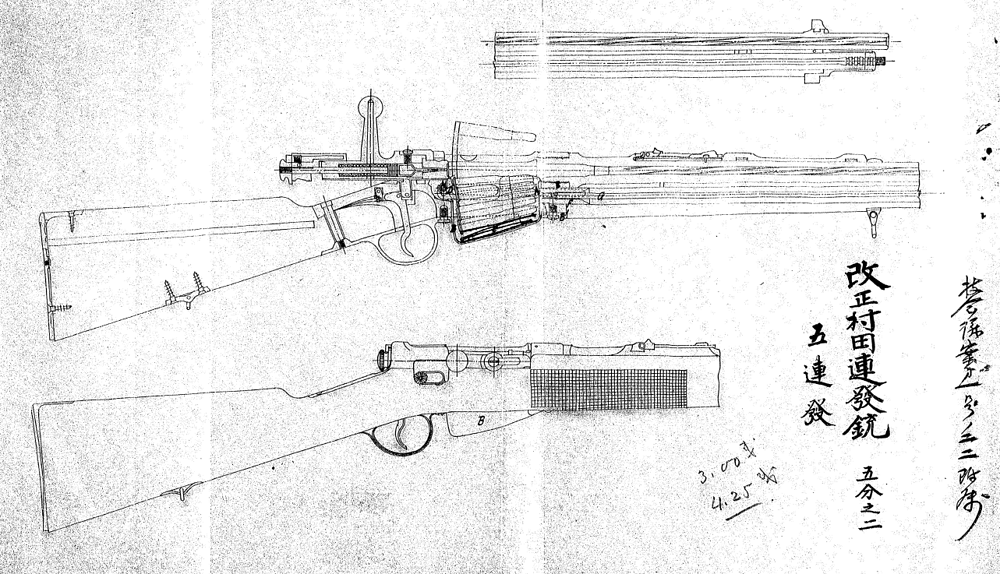

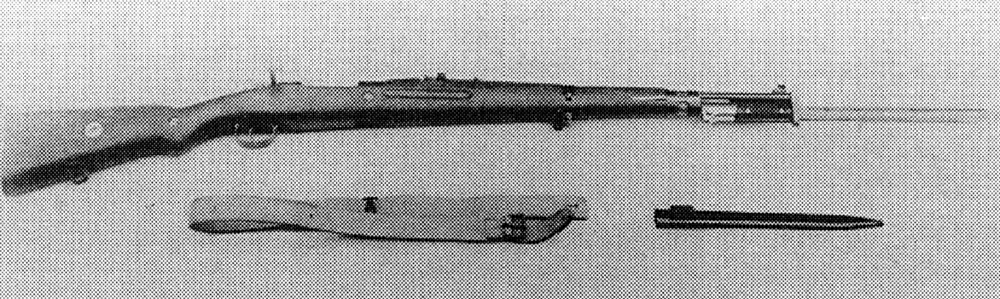

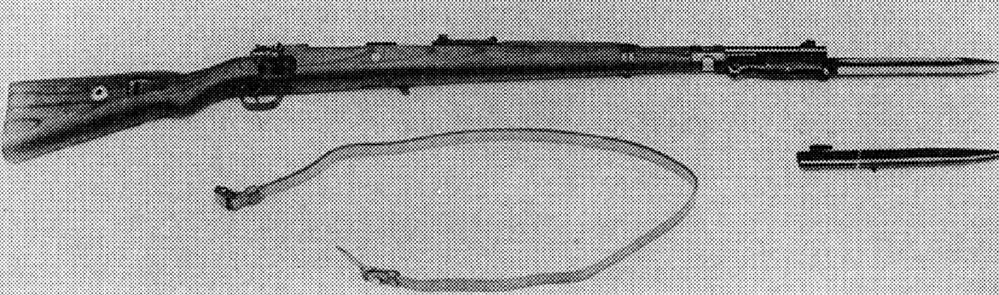

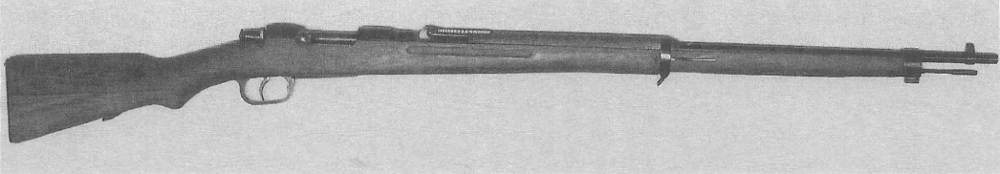

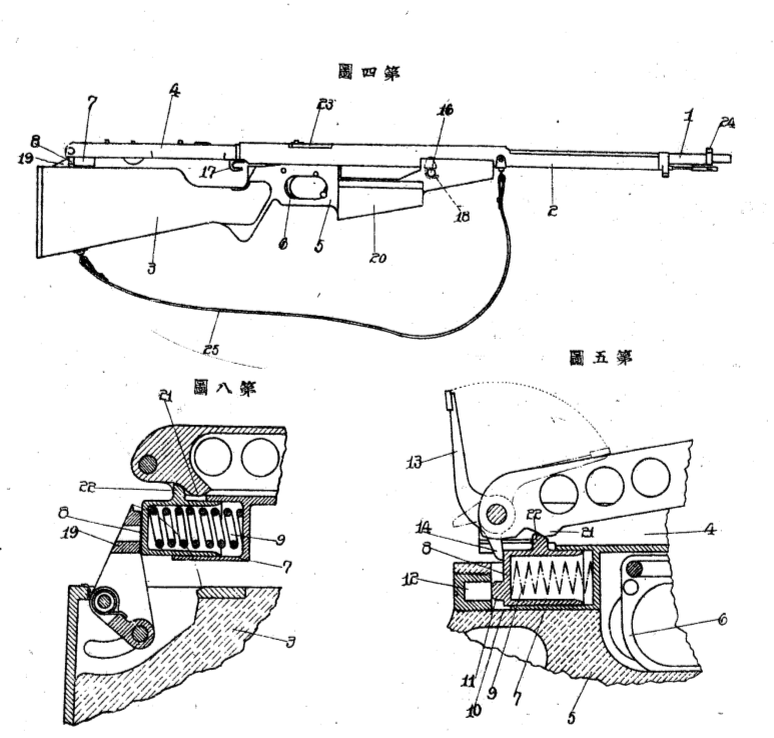

The design solutions embodied in the early Japanese light machine gun prototypes extended beyond the borders of the Empire. In March 1913, the Ordnance Department of the Republic of China initiated a standardization program, tasking the Shanghai and Dezhou arsenals with analyzing foreign automatic weapons. By June 1913, the decision was made to focus specifically on the “latest Japanese machine gun” (the 1908 prototypes based on the Type 38), modifying it to fire the standard Chinese 7.92mm Mauser cartridge. Under the leadership of Han Lin-chun at the Shanghai Arsenal, this project culminated in May 1915 with successful field trials at the Nanyuan range. The weapon was officially adopted as the Type 4 light machine gun. Today, the surviving documentation and technical data regarding the Chinese Type 4 are more comprehensive than the records for the original Japanese 1908 models, allowing researchers to effectively fill the gaps in our understanding of the Japanese prototype’s design and functionality.

The Chinese Type 4 light machine gun is a copy of the Japanese model, though it features minor differences.

| Specification |

Type 4 |

| Caliber |

7.92 mm |

| Mass |

8.400 kg |

| Total Length |

1,170 mm |

| Barrel Length |

600 mm |

| Rate of Fire |

450 rpm |

| Feed System |

30-round rigid strips |

More photos

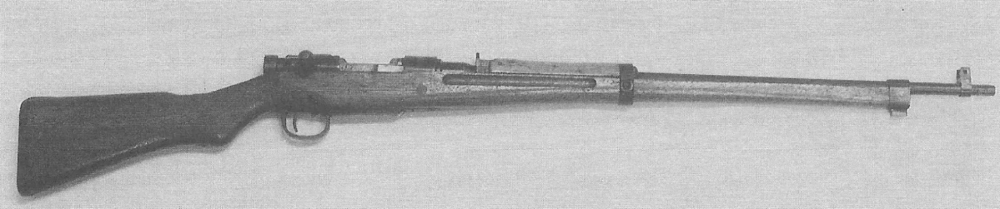

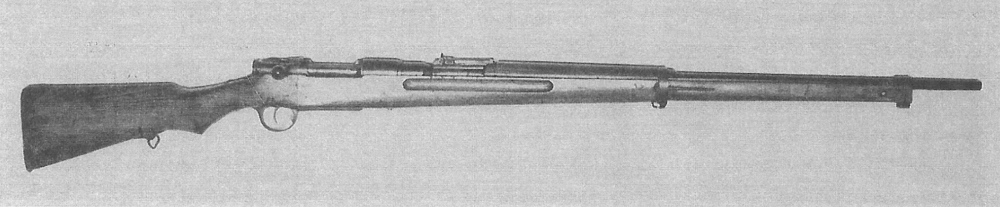

Chinese Type 4 Light Machine Gun.

Chinese Type 4 Light Machine Gun.

Chinese Type 4 Light Machine Gun.

Chinese Type 4 Light Machine Gun.

Chinese Type 4 Light Machine Gun.

Following a hiatus, development resumed in 1914 using the Type 3 heavy machine gun as a mechanical foundation. Between 1915 and 1919, the Army Technical Department experimented with various cooling and weight-reduction configurations. This period saw the creation of the 11 kg Model Ko, Otsu, and Hei variants (1915-1916), followed by specific studies into heat dissipation.

| Mass (kg) |

Model Ko |

Model Otsu |

Model Hei |

| Total weight |

11.7 |

7.8 |

9.9 |

| Gun weight |

8.5 |

7.8 |

6.7 |

| Tripod weight |

3.2 |

|

3.2 |

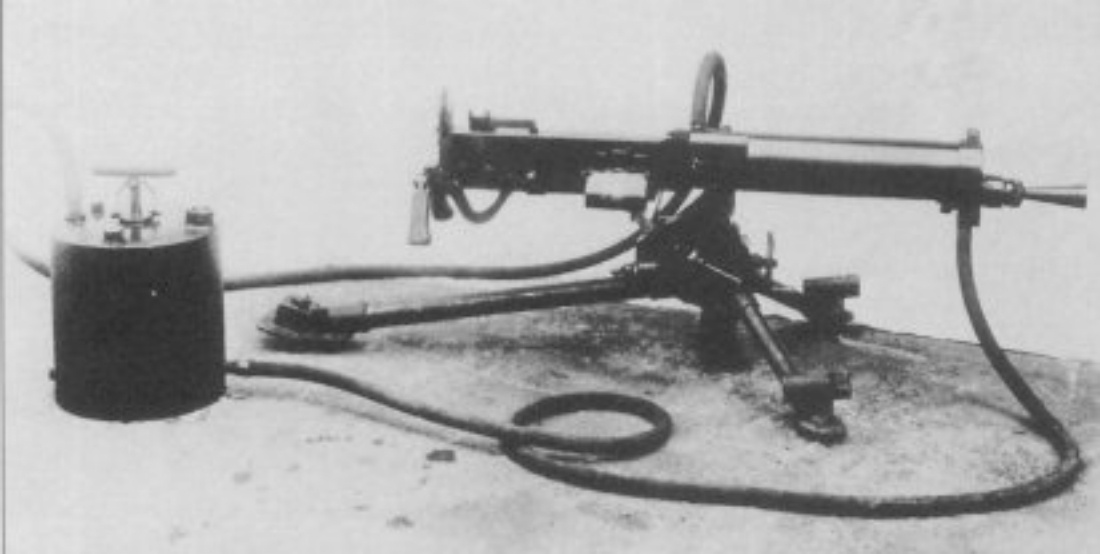

Engineers produced a Radiator Type with a cooling jacket in 1918, and subsequently developed Non-Radiator versions to shed weight, eventually achieving a late-model variant in 1919 that weighed only 8 kg.

Exercises with the radiator-type machine gun.

More photos

1918 radiator-type machine gun.

1918 radiator-type machine gun.

Non-radiator type machine gun.

A pivotal shift in the weapon’s evolution occurred in the early 1920s regarding its feeding system. In 1920, a Model Ko was developed featuring a disk magazine, reflecting a departure from the traditional rigid feed strips. However, inspired by discussions with Colonel Kunishi about the need for rapid reloading in close quarters, Nambu pivoted to a revolutionary hopper magazine. This led to the 1921 Model Otsu, which allowed the gun to be fed with standard 5-round infantry stripper clips, significantly simplifying field logistics.

Model Otsu machine gun. Note the magazine, which is identical to that of the Lewis gun. The number of ribs on the magazine and the scale are the same.

More photos

Model Otsu machine gun.

Model Otsu machine gun.

The path to final adoption was finalized during extensive trials in 1922 at the Infantry and Cavalry Schools. While the 18 experimental samples demonstrated impressive barrel longevity—maintaining accuracy even after 20,000 rounds—the commission noted persistent issues with cartridge misalignment and ejection failures. Despite these mechanical “teething problems,” the Japanese Army leadership decided to adopt the weapon immediately as the Type 11 LMG. They prioritized the urgent need for modernization over technical perfection, planning to refine the weapon’s reliability through actual combat experience.

Type 11 serial production machine gun.

| Year |

Designation |

Description |

| 1908 |

Model Ko / Otsu |

Light variant of the Type 38 machine gun. |

| 1915-1916 |

Model Ko / Otsu / Hei |

Light variant of the Type 3 machine gun; weight ~11 kg. |

| 1918 |

Radiator Type |

Features a cooling jacket for heat dissipation; weight ~10 kg. |

| 1918 |

Non-Radiator (Early) |

Cooling jacket removed; weight ~9 kg. |

| 1919 |

Non-Radiator (Late) |

Improved version of the 1918 model; weight ~8 kg. |

| 1920 |

Model Ko |

Equipped with a top-mounted disk magazine. |

| 1921 |

Model Otsu |

Predecessor to Type 11; charging handle located on the right. |

| 1922 |

Type 11 |

Final production variant adopted by the Imperial Army. |

| Specification |

Type 11 |

| Caliber |

6.5 mm |

| Overall Length |

1.10 m |

| Total Weight |

10.3 kg |

| Muzzle Velocity |

736 m/s |

| Maximum Range |

3700 m |

| Rate of Fire |

500 rpm |

| Feed System |

Hopper (using stripper clips) |

| Magazine Capacity |

30 rounds |

| Bullet Weight |

9 g |

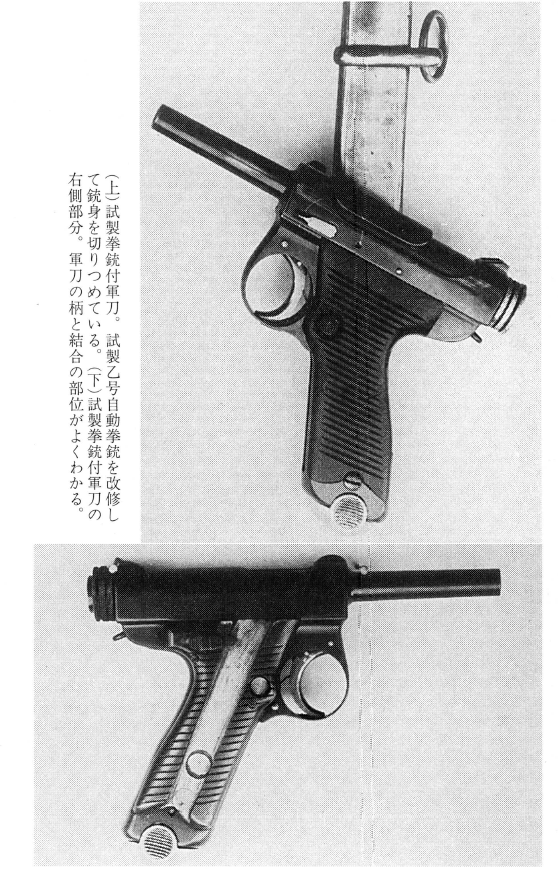

Type 11-based Prototypes

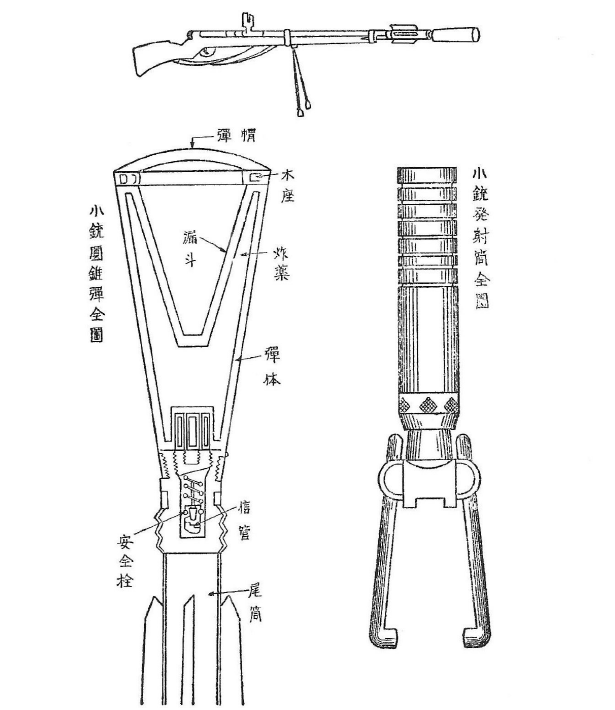

In March 1924, two prototypes were produced, chambered for the experimental 7.7mm cartridge. The modernization involved replacing the barrel and redesigning the chamber, hopper, and feed line to accommodate the larger ammunition. The safety mechanism and barrel attachment were also modified, and the bipod was made extendable to nearly double its length for better stability.

Trials at the Futtsu range revealed critical structural weaknesses. While semi-automatic accuracy matched that of a 7.7mm infantry rifle, the increased power of the cartridge caused the frame to fail. Prototype No. 261 suffered a bolt group failure after 1,095 rounds, while No. 330 experienced a broken receiver pin after 3,706 rounds. The tests proved that a simple conversion of the Type 11 to a larger caliber was impossible, necessitating an entirely new design.

Presumably a 7.7mm caliber Type 11 machine gun.

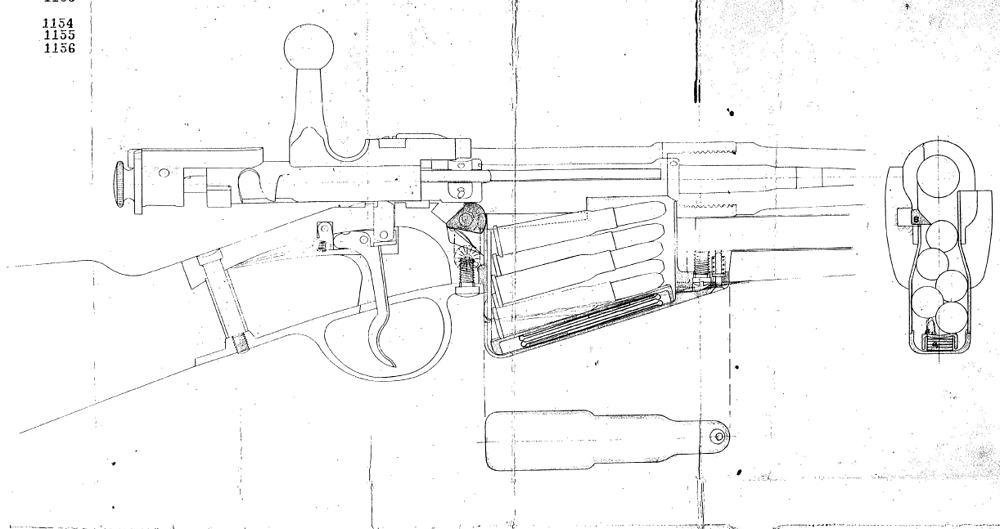

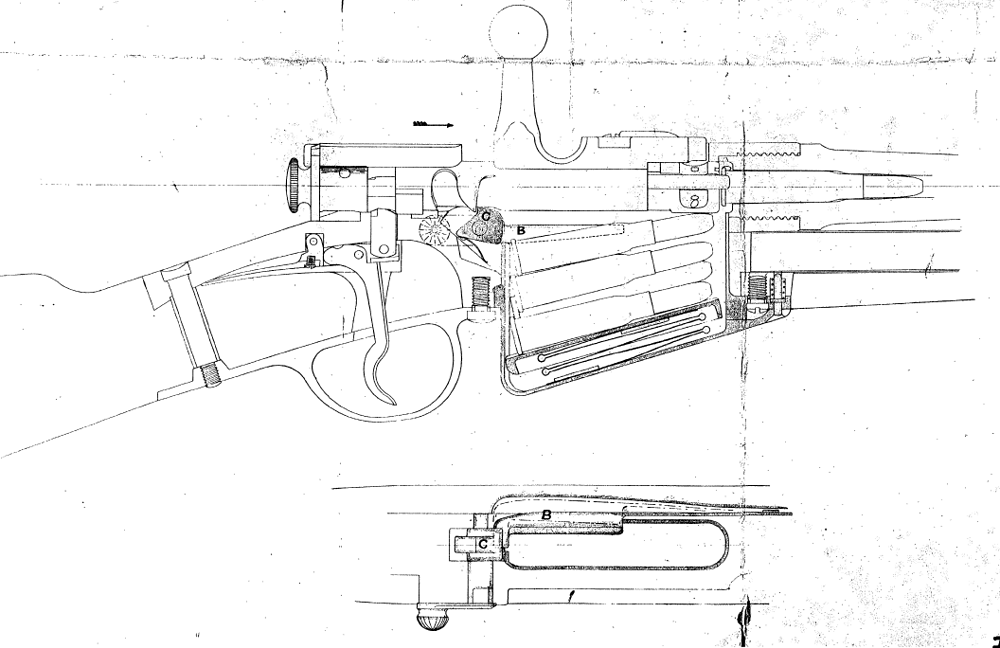

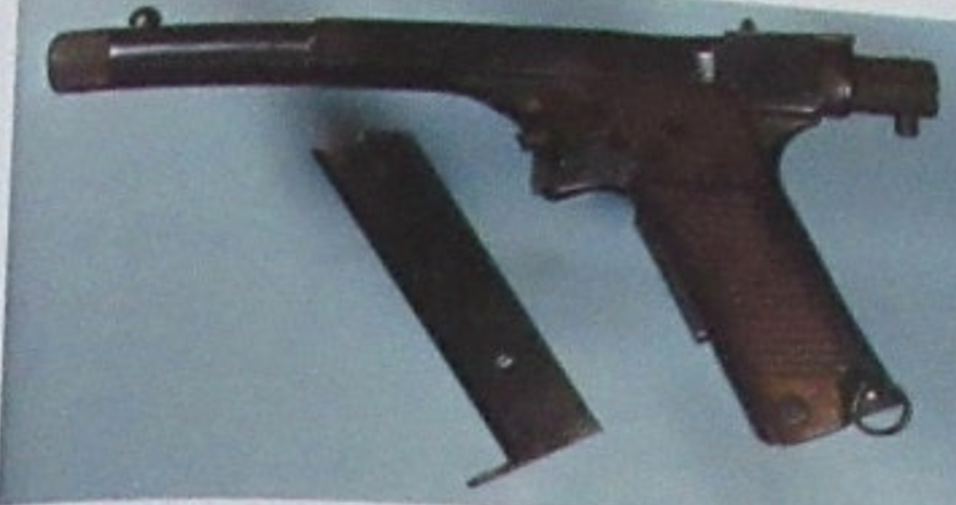

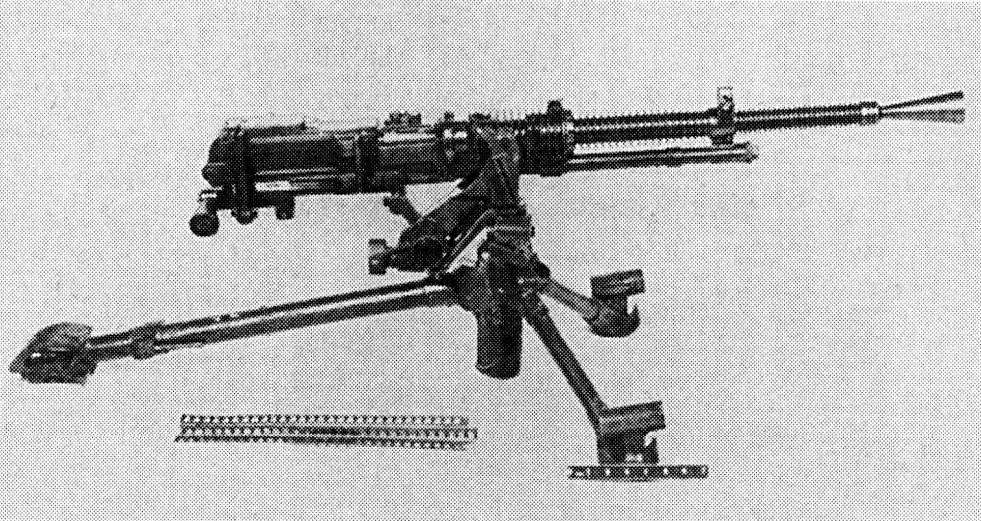

By 1928, engineers addressed the Type 11’s primary weakness—the vulnerable hopper system—by developing a version with a 35-round box magazine. This radically improved reliability and reduced sensitivity to dirt.

The weapon also received several ergonomic upgrades:

- Bipods capable of anti-aircraft fire.

- A rear monopod on the stock (similar to the later Type 99 system) to create a “tripod” effect for stability.

- A Lyman-style aperture sight for better accuracy.

- A dedicated semi-automatic fire mode.

- Although not adopted, its advancements in ergonomics and sighting were incorporated into later Japanese designs.

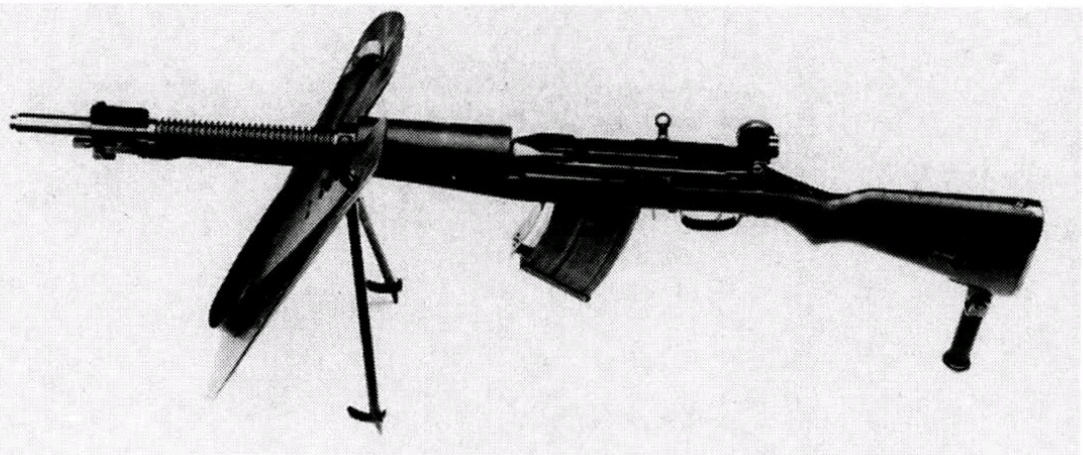

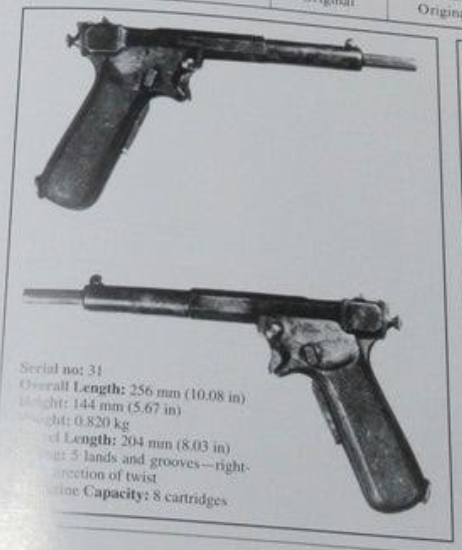

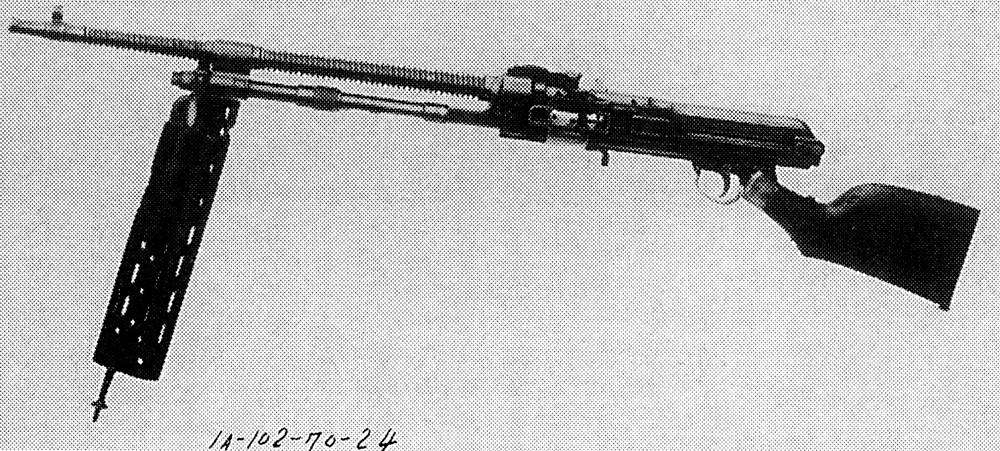

The only photo of a Type 11 with a box magazine. I should note that the magazine shown below matches the dimensions of a 20-round magazine more closely, but it is certainly not for 35 rounds. Furthermore, the lack of a curve on the magazine is perplexing, and the purpose of the device to the right of the magazine in the photo remains unclear. I also want to draw attention to the long horizontal magazine well; I can only speculate that 35 rounds were accommodated by both the magazine itself and the magazine well, similar to the Johnson 1941 machine gun, but unfortunately, nothing can be said for certain. Additionally, note the shortened stock, which was apparently made to simplify production or for the convenience of the cavalry.

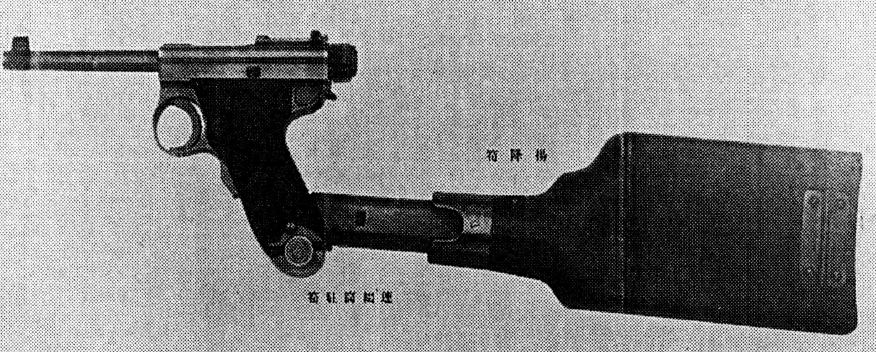

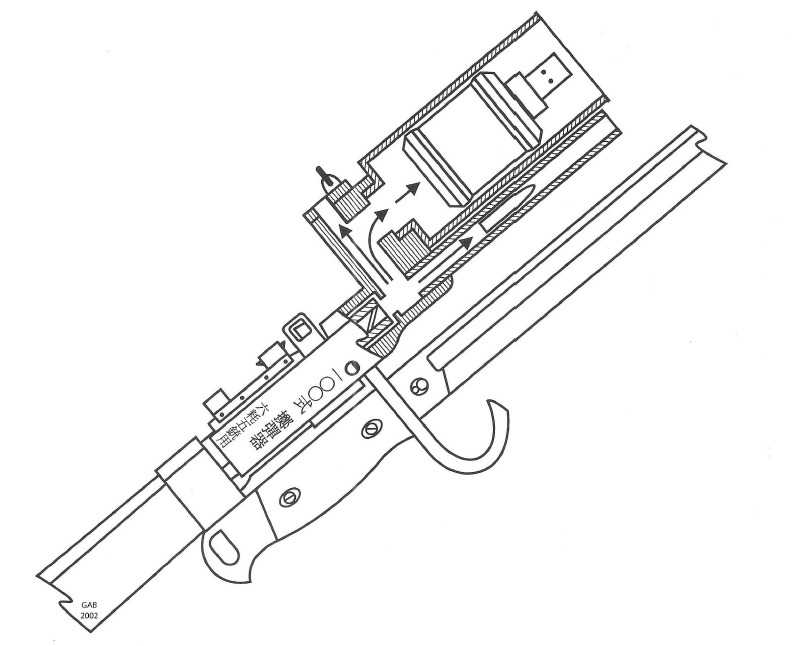

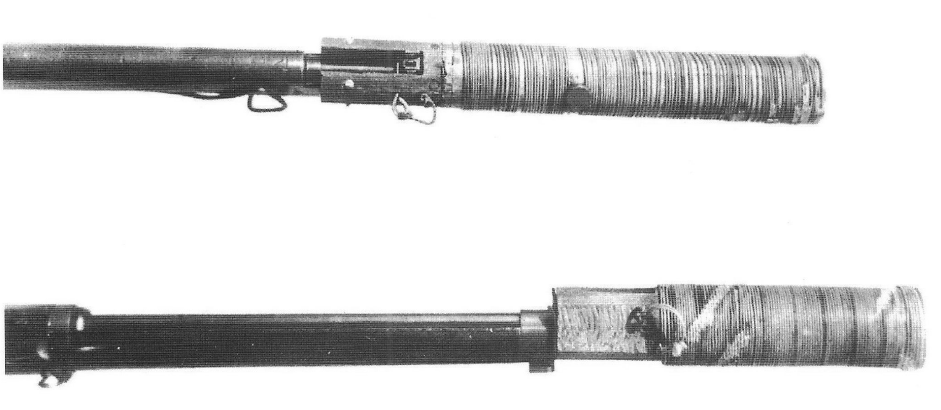

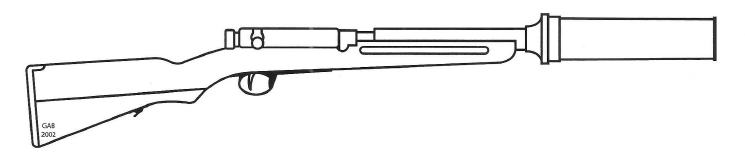

One of the most unusual experiments was a device designed for firing from cover, overseen by Lieutenant Colonel Yoshikazu Dokin. To meet the demands of positional warfare, the design featured a folding stock with a ratchet mechanism that could be rotated 180 degrees. This allowed the soldier to fire from behind cover while aiming through a periscopic optical sight developed by Tokyo Optical. Despite reaching a functional stage, the project was canceled by 1941 due to the high cost and complexity of the optical components.

Type 11 machine gun for firing from behind cover.

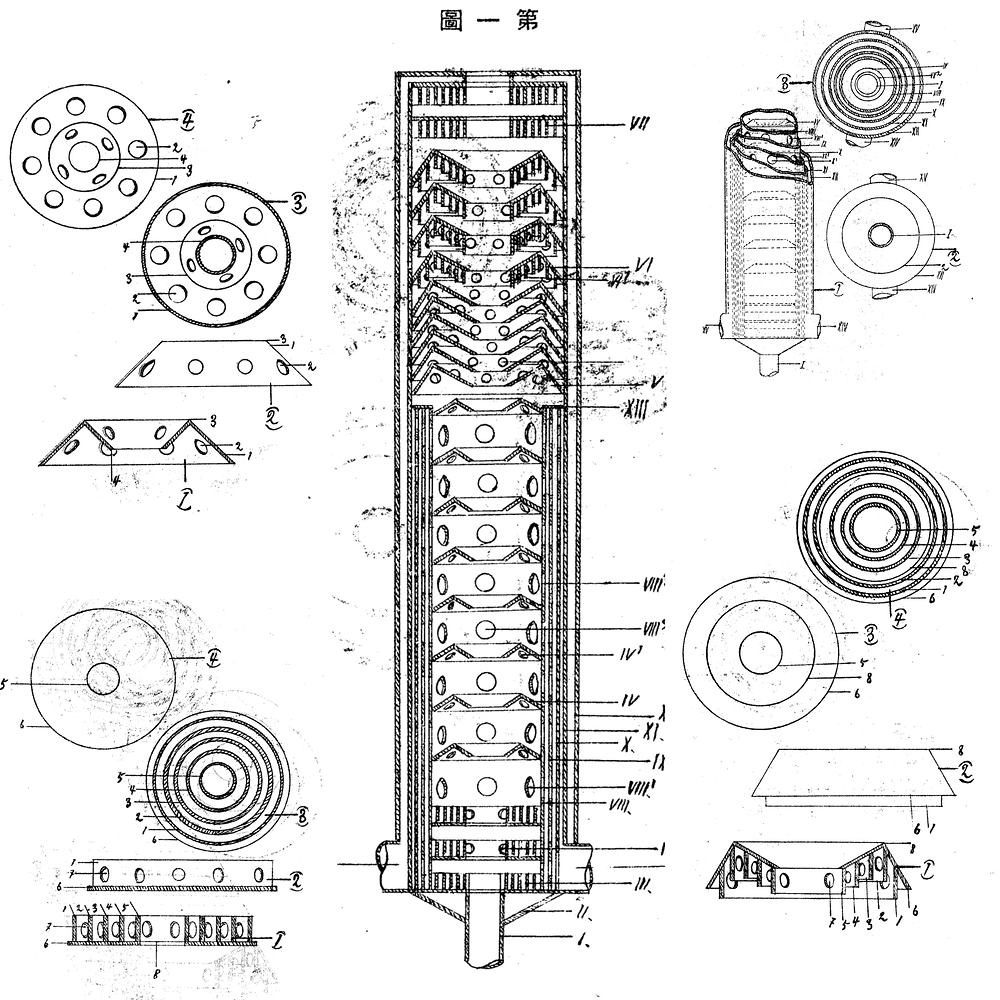

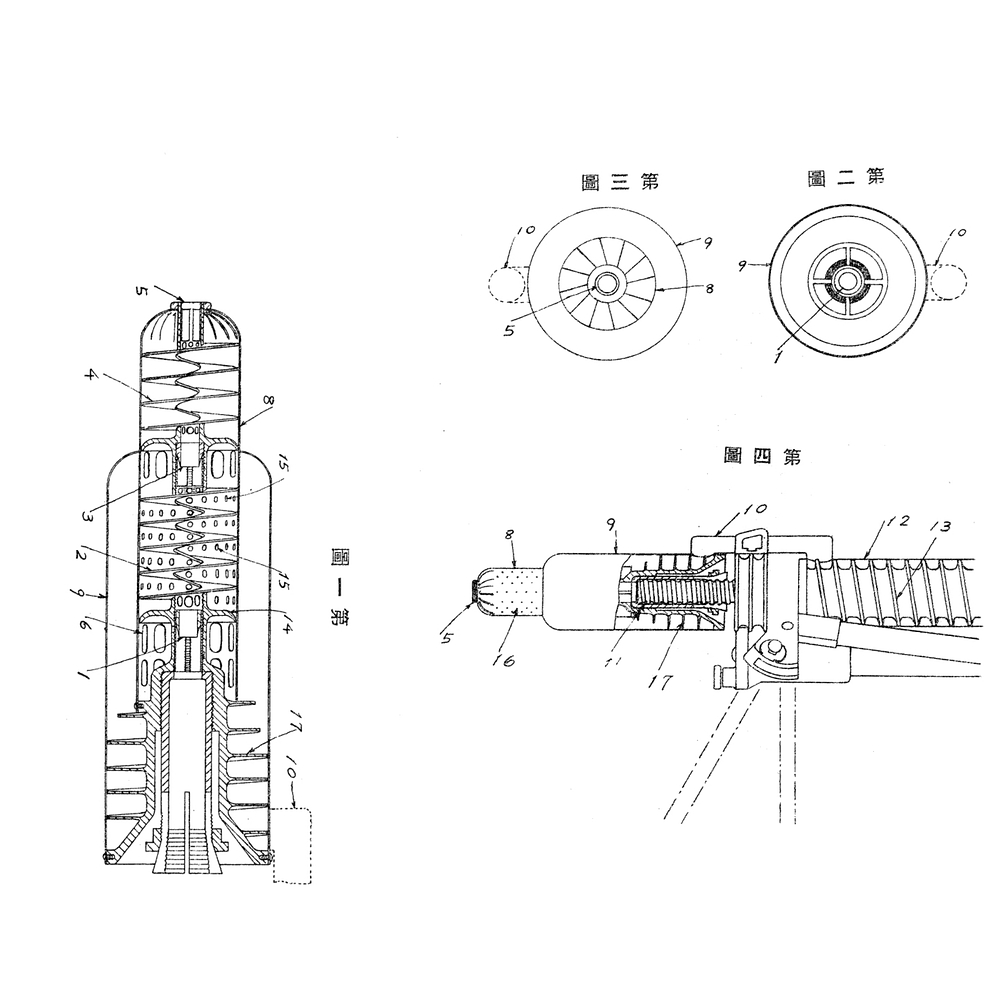

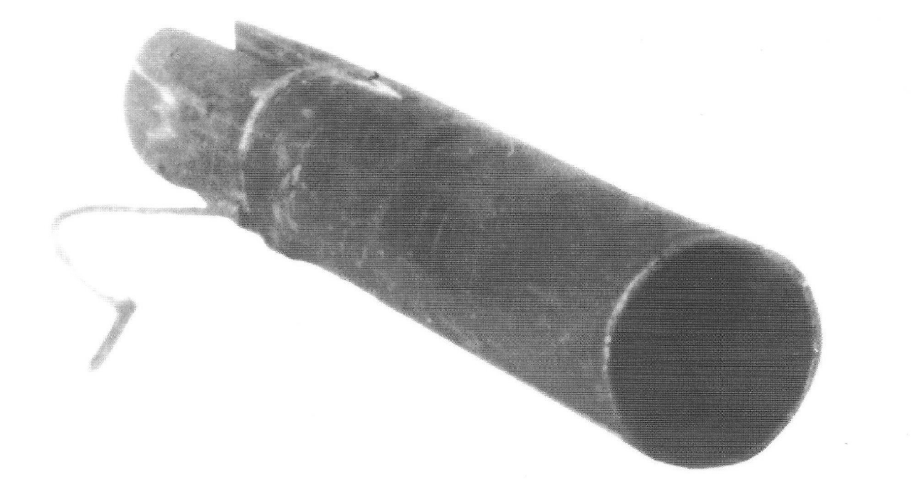

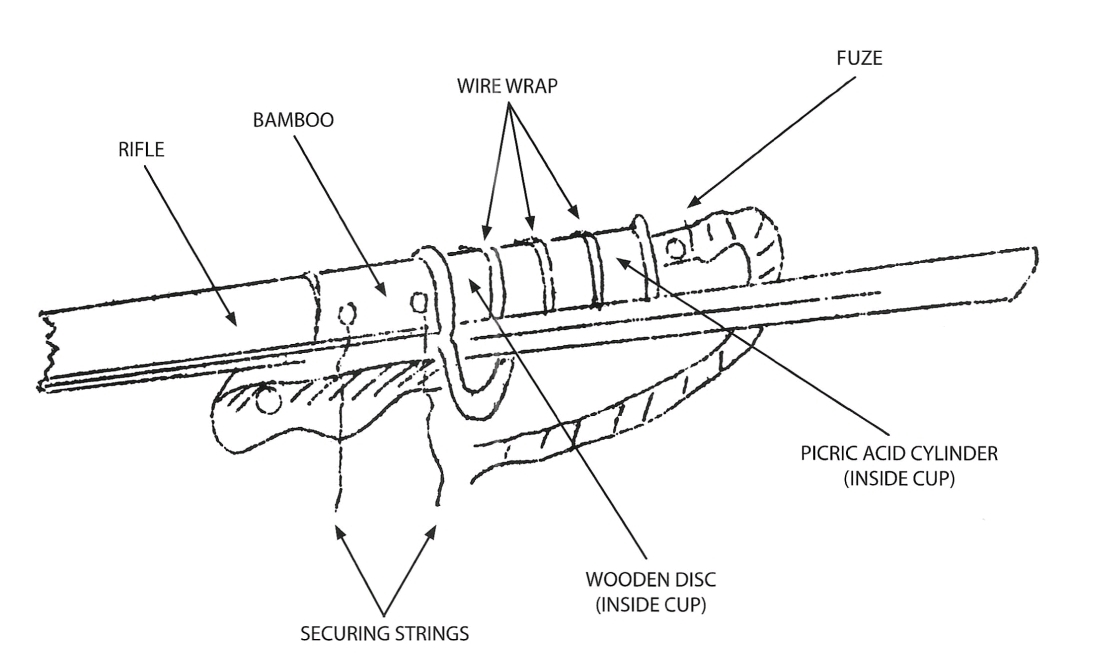

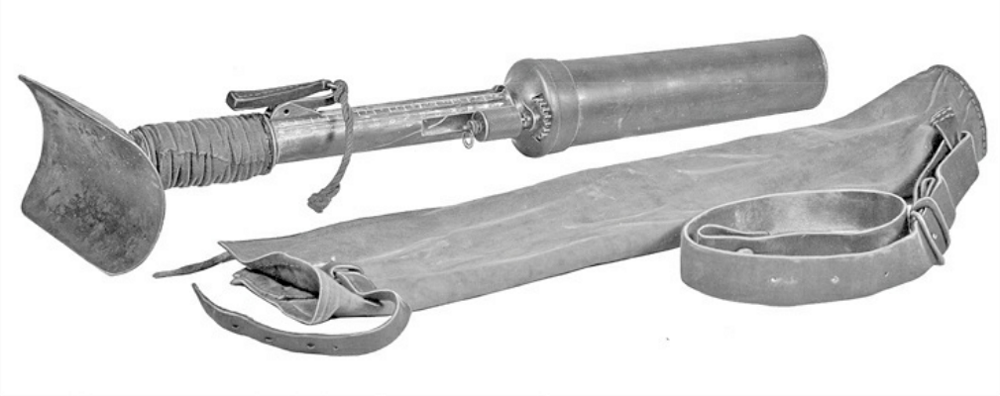

As discussed in the “Bolt-action Rifle” chapter (see section “Type 38 Rifle”), inventor Kinzaburo Hibino proposed an evolution of H.P. Maxim’s silencer design. The distinctive feature of this invention was its compatibility with automatic weapons.

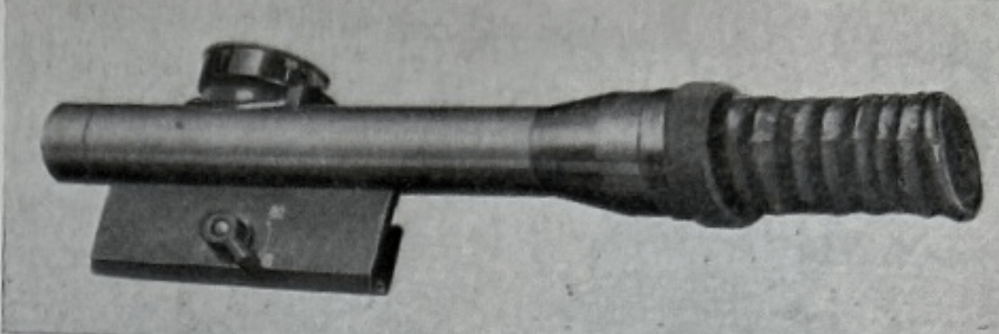

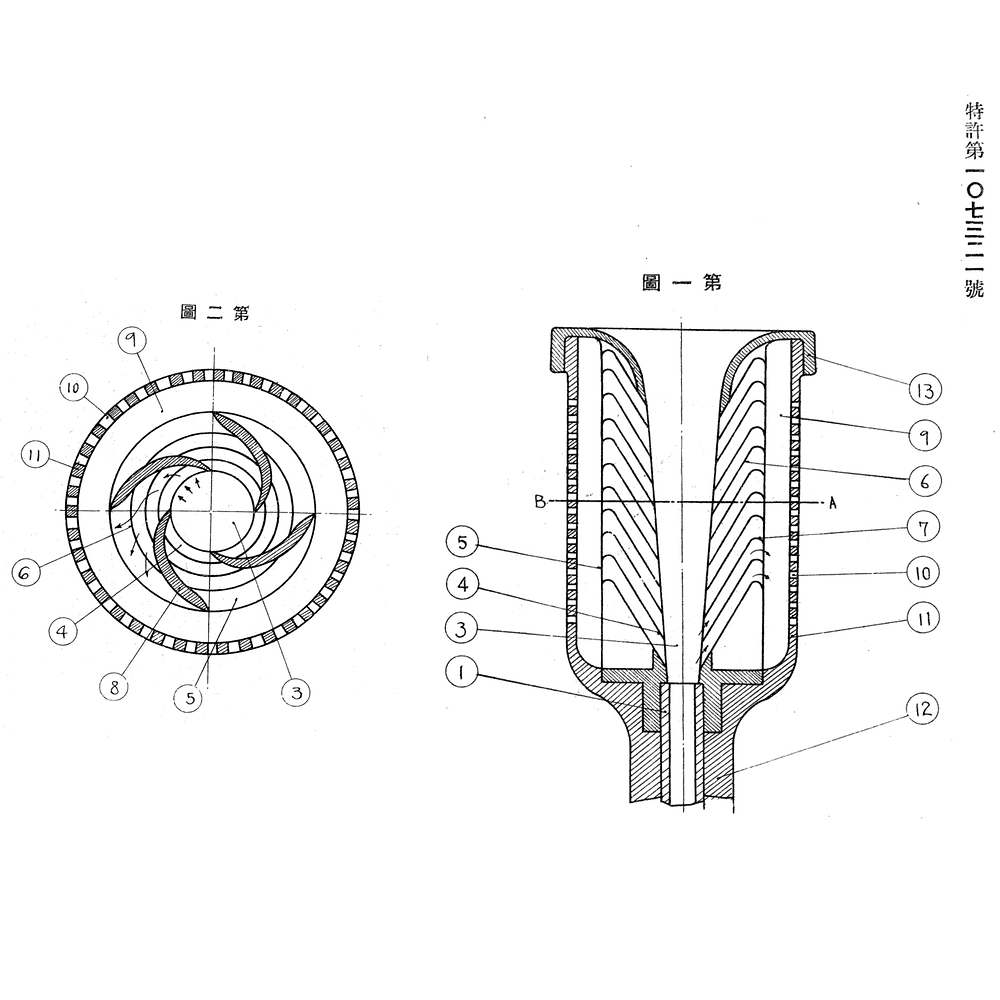

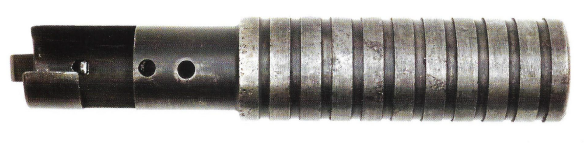

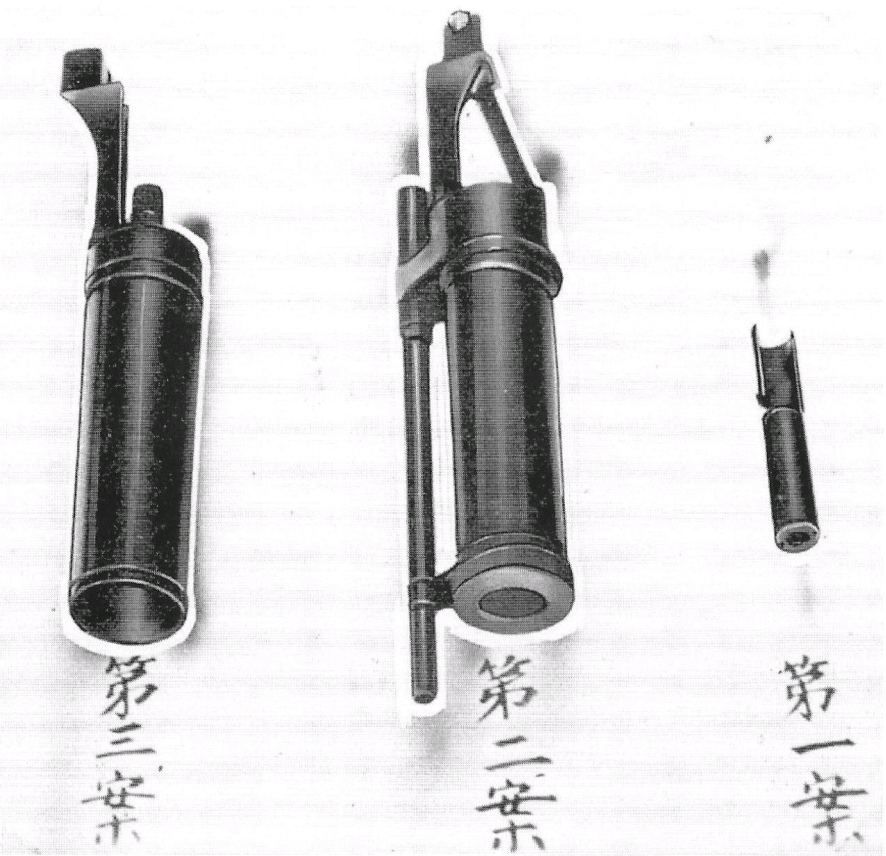

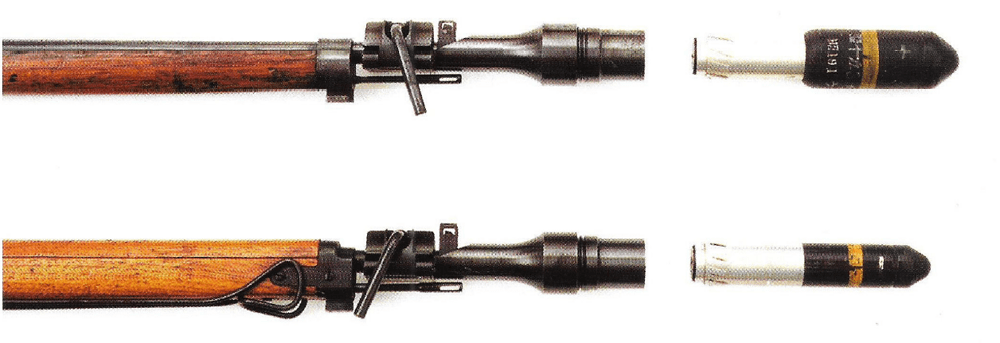

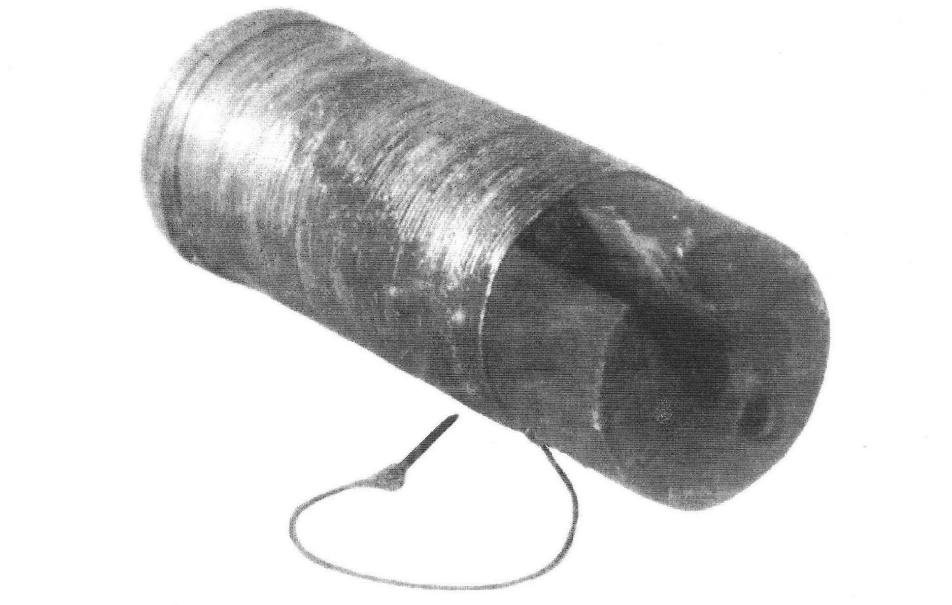

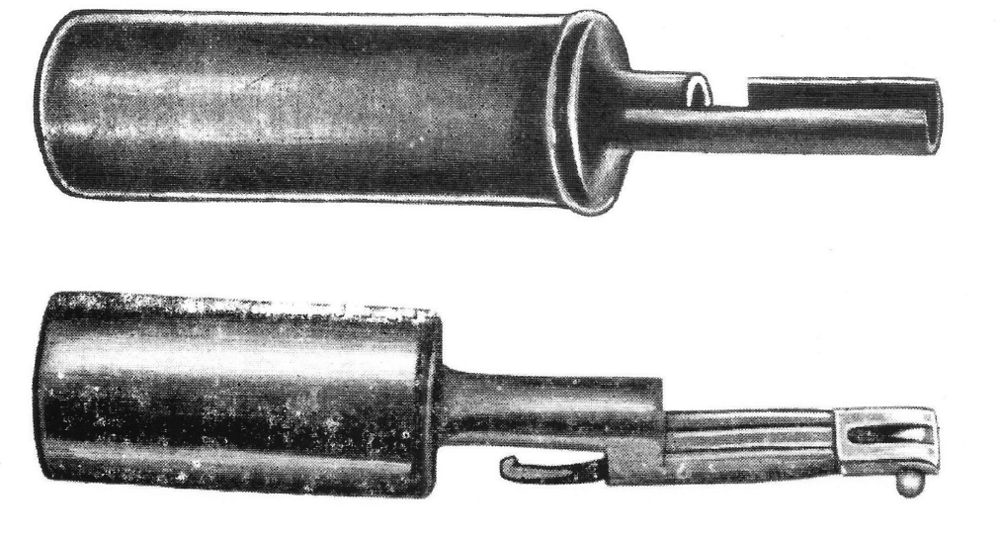

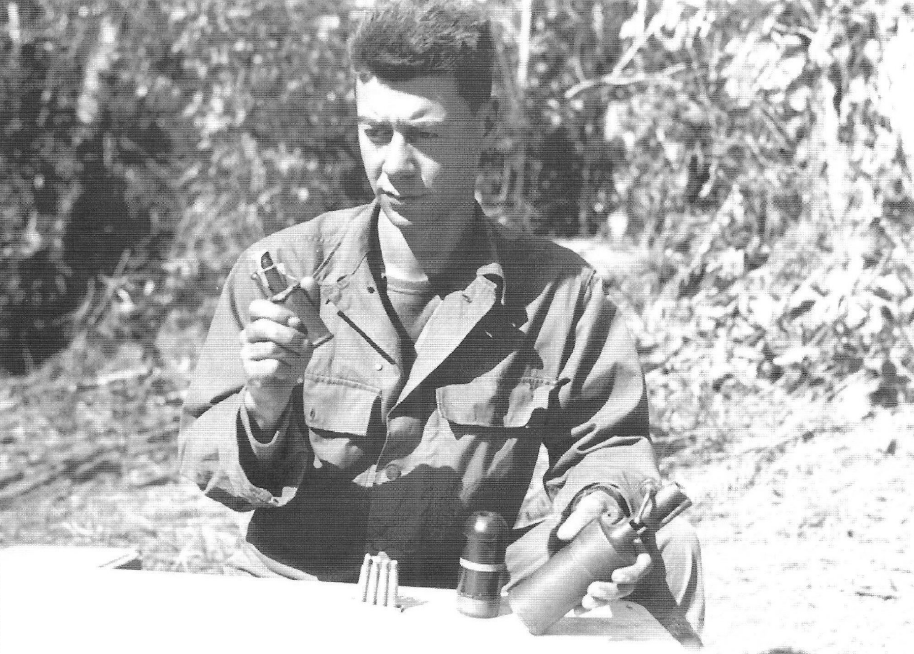

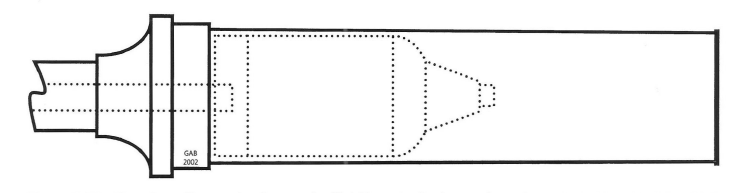

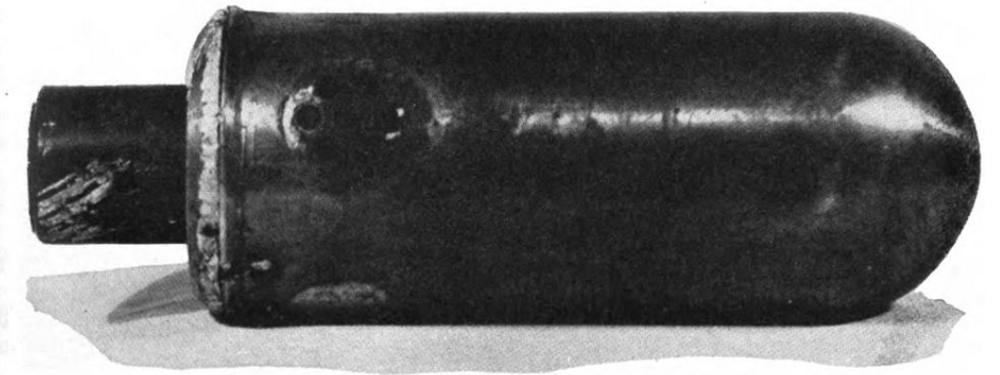

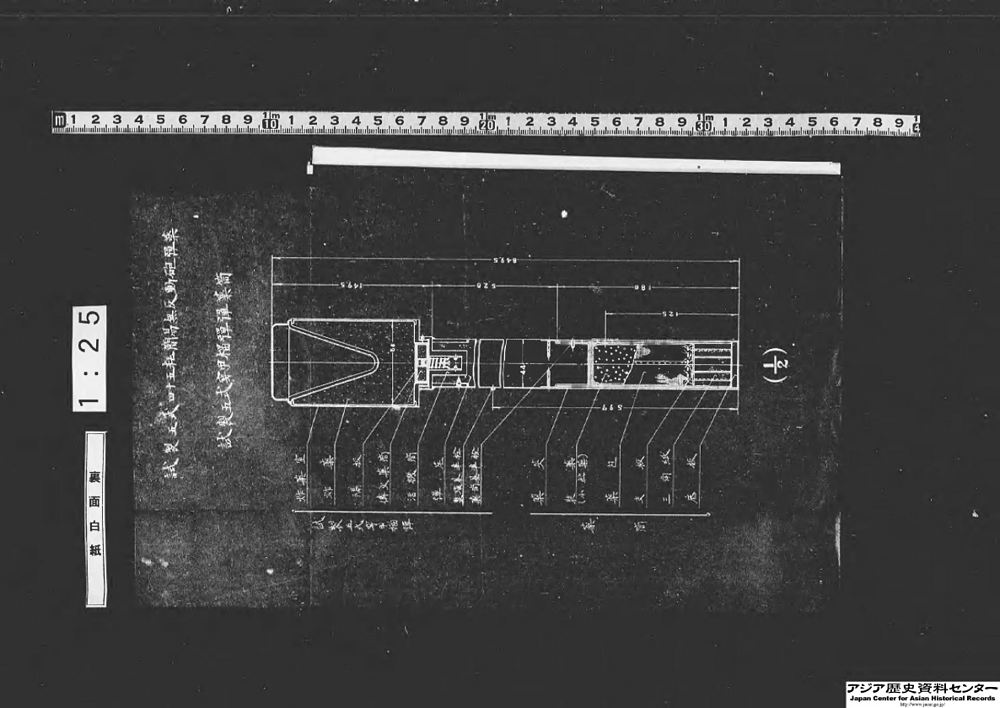

The 1928 device developed by Kiyoshi Kogure was a specialized suppressor designed for the Type 11 light machine gun, particularly for units mounted in armored vehicles. To prevent smoke accumulation and the stunning effect of noise on the tank crew, Kogure developed a detachable silencer featuring five concave disks. Its casing was ribbed to enhance heat dissipation and featured perforations to allow for the gradual, controlled release of propellant gases.

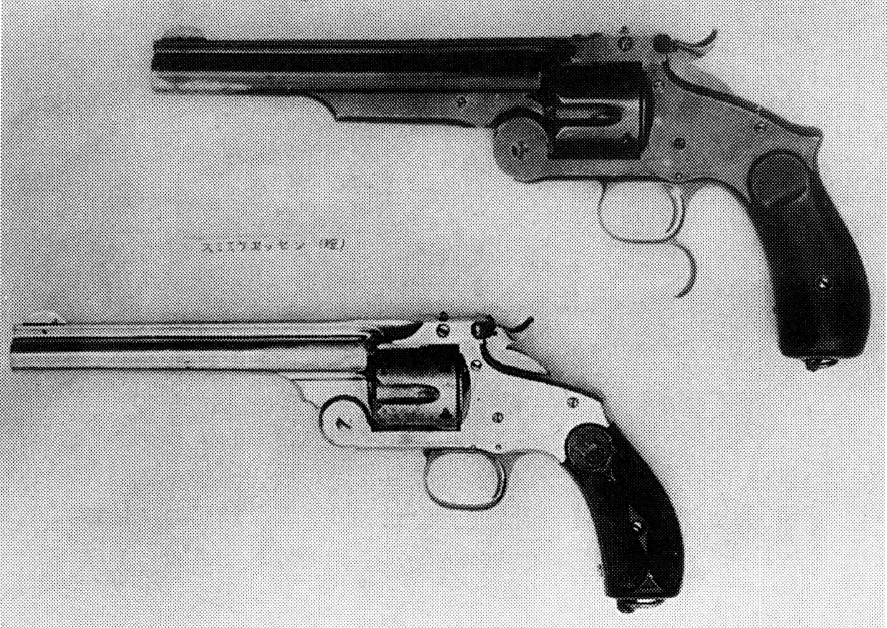

Kiyoshi Kogure suppressor, 1928.

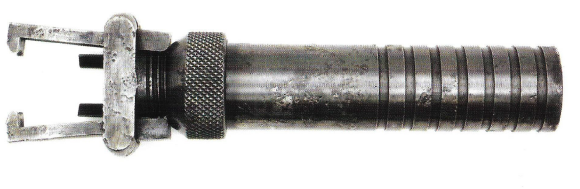

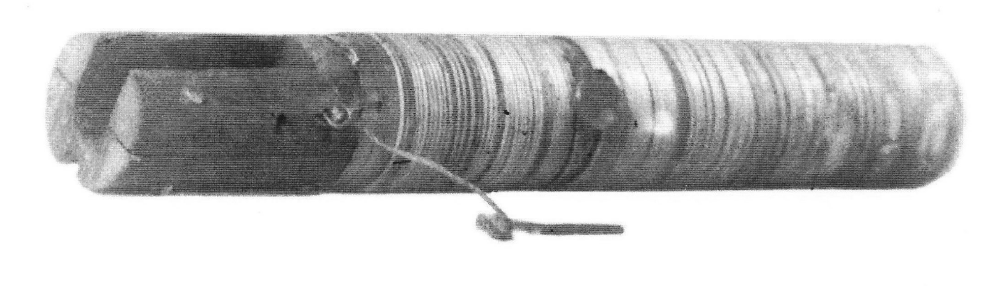

On April 26, 1933, a patent was approved for a simplified suppressor model designed by Kiyoshi Kogure.

Kiyoshi Kogure suppressor, 1933.

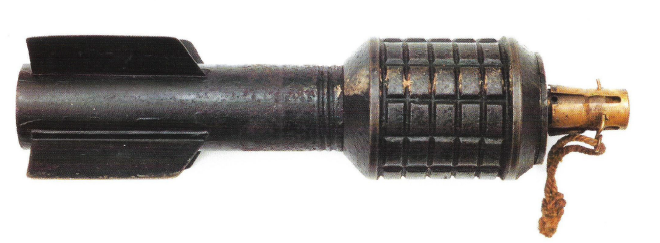

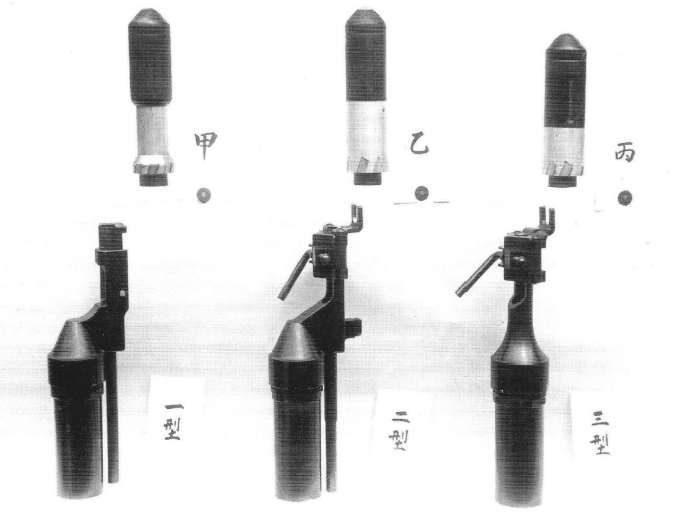

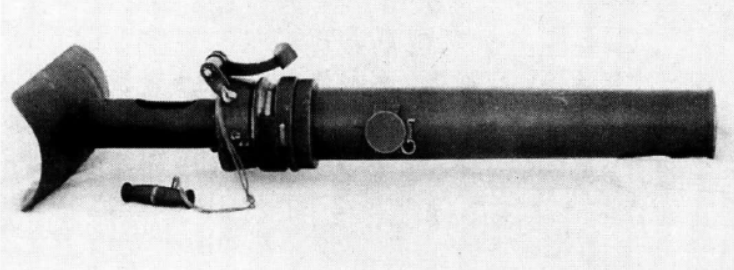

The 1933–1934 Tatsuo Aida attachment functioned as a universal device, combining the capabilities of a sound suppressor with a muzzle brake-compensator. Inside its cylindrical housing were eleven funnel-shaped elements. The front section of the device was equipped with specialized ribs designed to create gas turbulence, which significantly increased the efficiency of both sound and recoil suppression.

Tatsuo Aida suppressor, 1933-34.

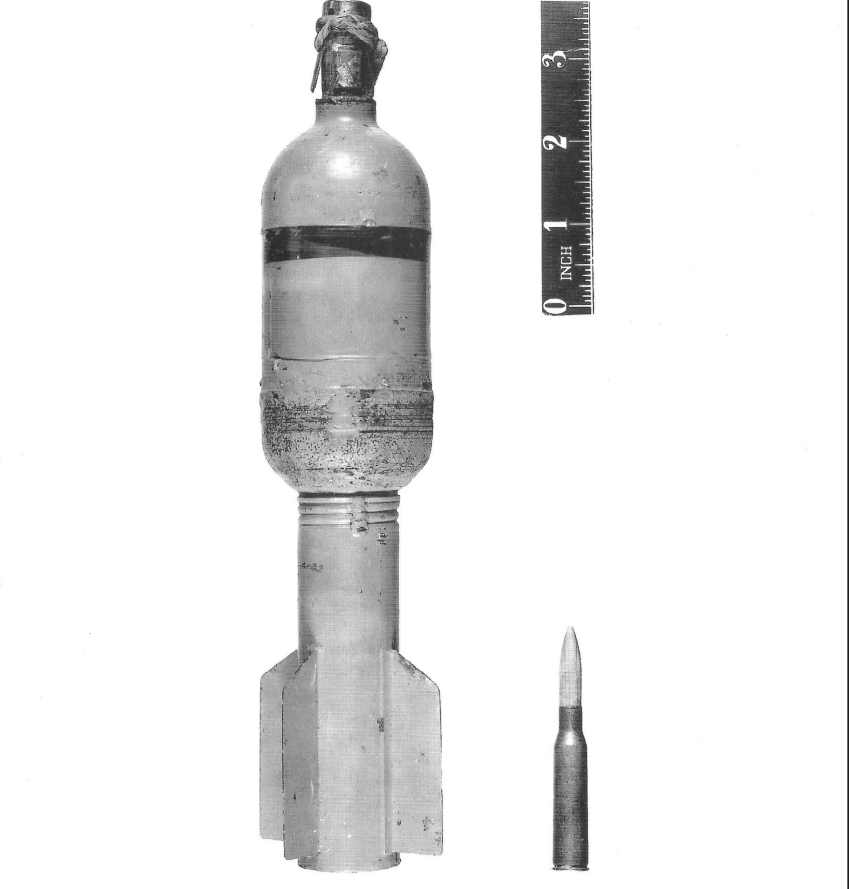

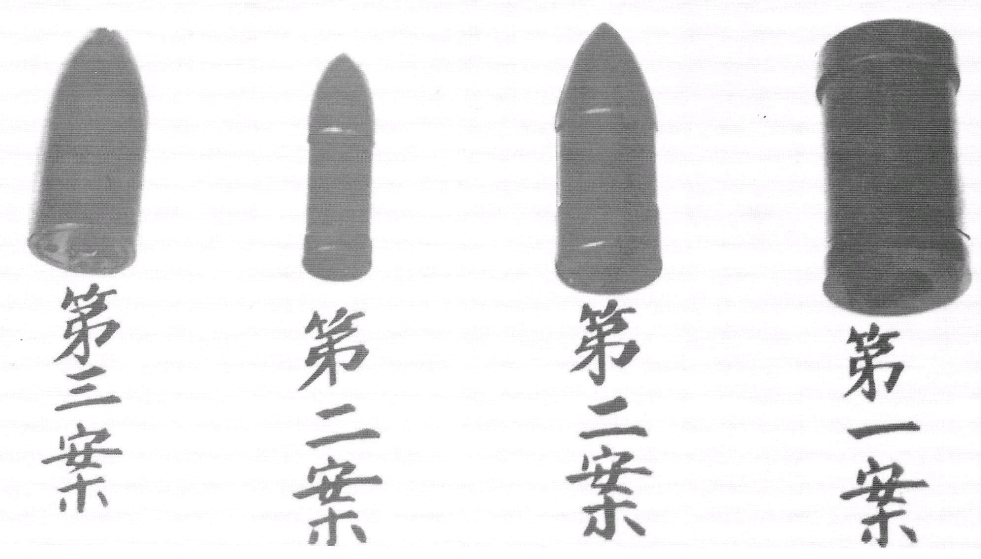

The 1934 Kihachi Kato suppressor was a “machine gun and rifle” device distinguished by its double-walled casing. Its most notable technical feature was the use of two internal helical (spiral) gas diffusers. The design emphasized practical field use, allowing for rapid mounting and easy cleaning, while an enlarged bore clearance ensured that the device had a minimal impact on the weapon’s ballistic accuracy.

Kihachi Kato suppressor, 1934.

The 1935 improved Kato suppressor represented a significant modernization of his previous design, specifically adapted for the rigors of sustained automatic fire. The primary innovation was the integration of a robust radiator featuring six transverse cooling fins. The system was engineered to utilize the airflow drawn through the front slots to provide forced cooling for both the gun barrel and the suppressor body during rapid bursts.

Kihachi Kato suppressor, 1935.

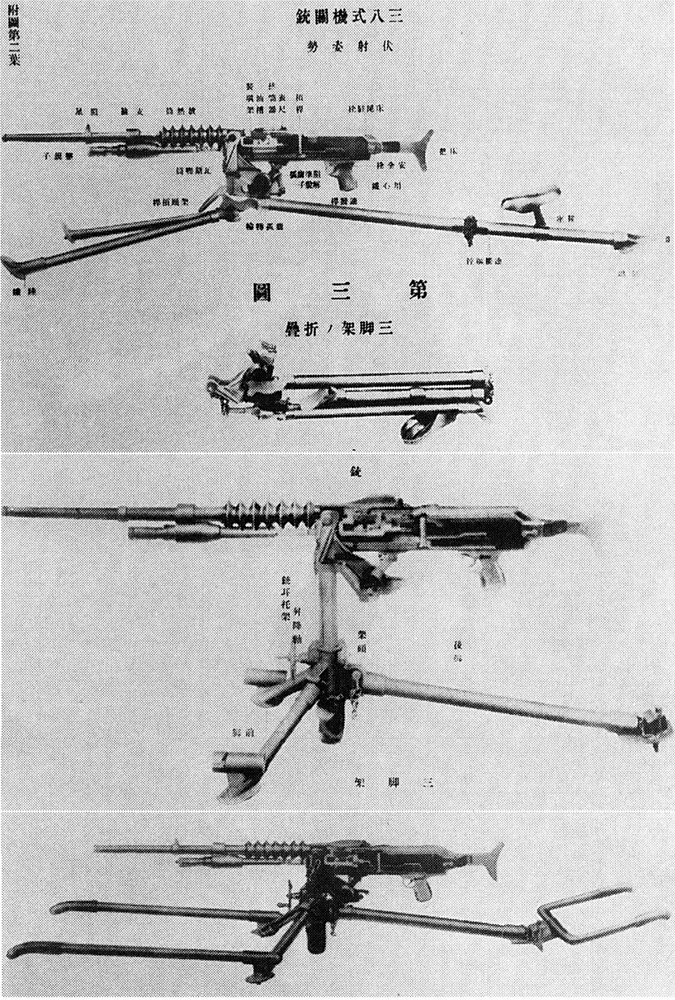

Type 92 Machine Gun

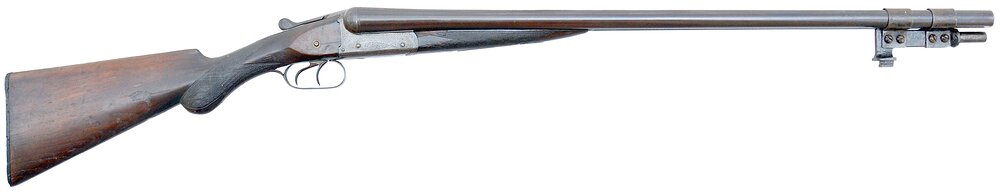

Japan interest in the Lewis light machine gun began in early 1913, when Japanese representatives attended demonstrations in Bisley, England. In 1915, the Japanese firm Mitsui and Company Ltd. (Mitsui Bassan Kaisha Ltd.), with offices in major countries, contacted the Automatic Arms Company, expressing interest in acquiring manufacturing rights or purchasing Lewis guns outright. This request was forwarded to the Belgian firm Armes Automatiques Lewis, which controlled distribution rights in Asia.

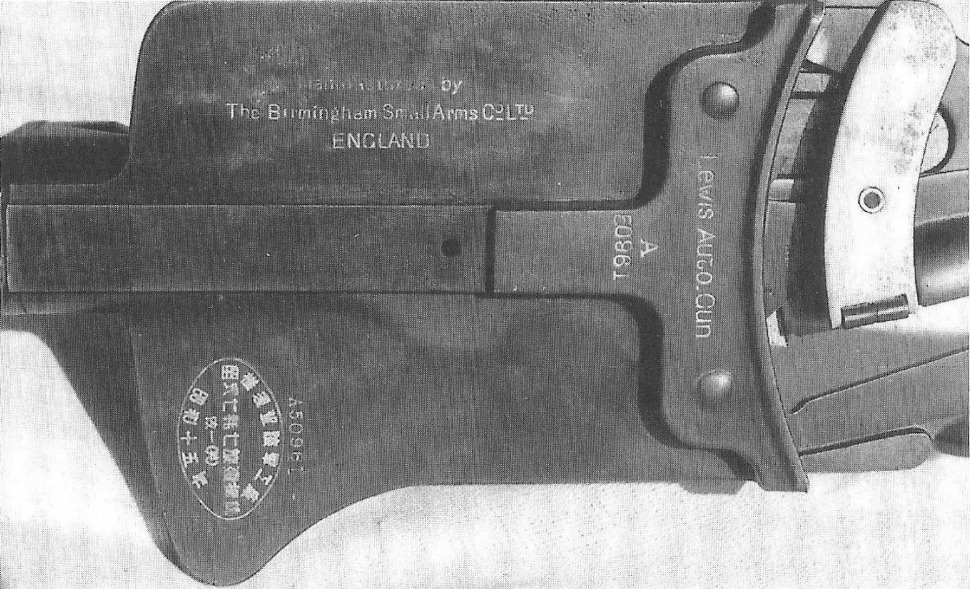

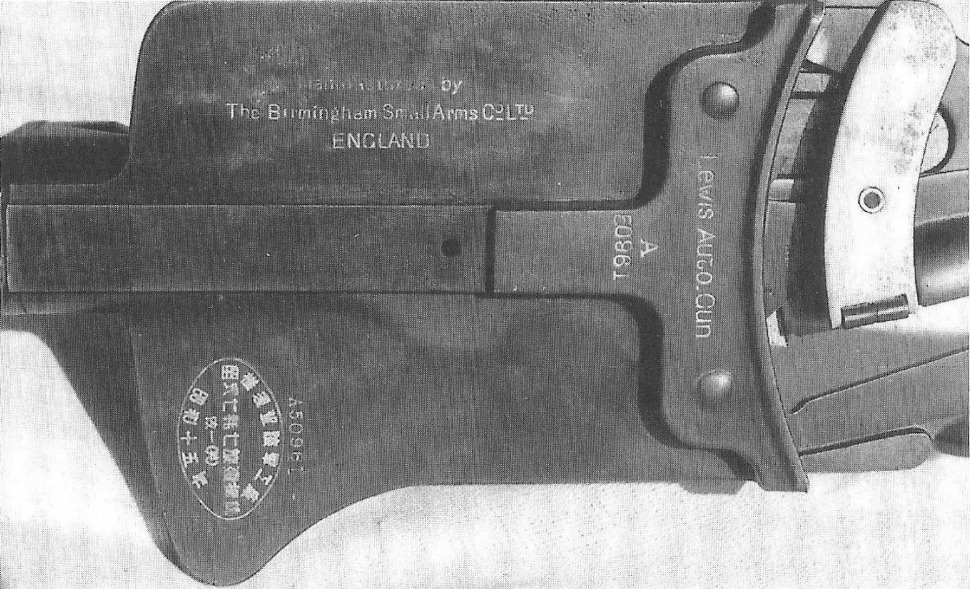

Further interest in the Lewis gun only arose after World War I, during which the Imperial Japanese government was allied with Great Britain. In 1927, Mitsui and Company Ltd., representing the Japanese government, began negotiations to purchase Lewis guns directly from BSA.

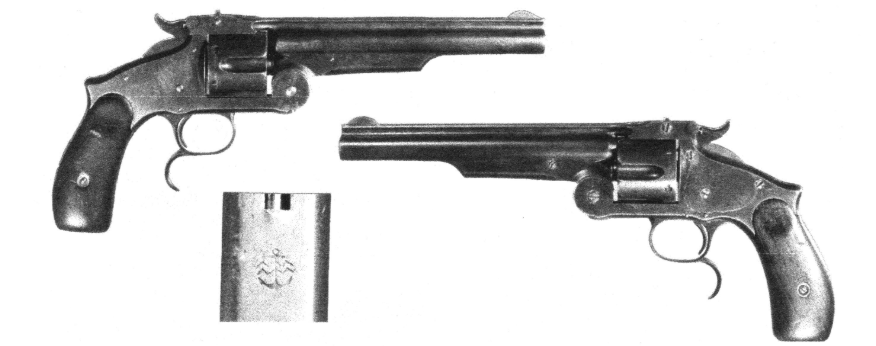

By 1929, BSA was supplying commercial Lewis guns to the Japanese Navy in the standard .303 British caliber, designated 7.7x56mm by the Japanese. The gun itself was designated “留式七粍七機銃”—“7.7mm rotary machine gun.”

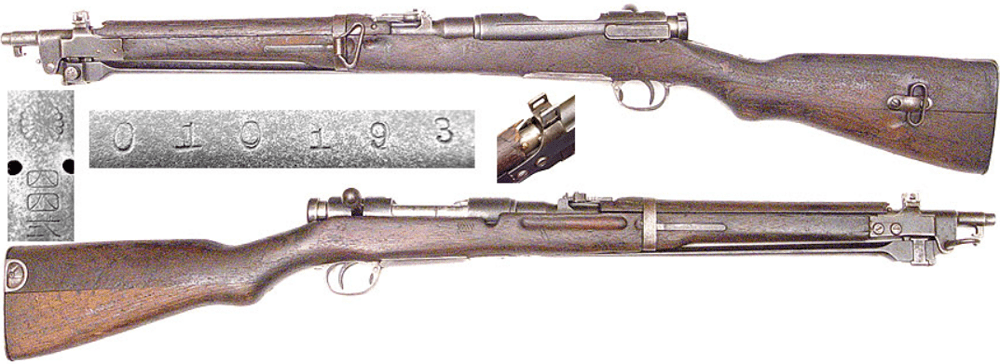

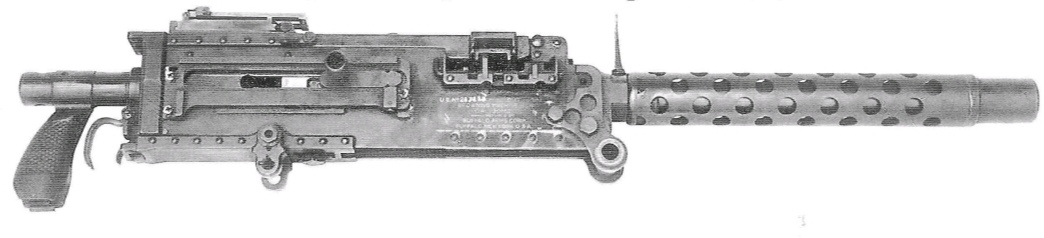

Lewis machine gun manufactured by BSA for the Japanese Navy.

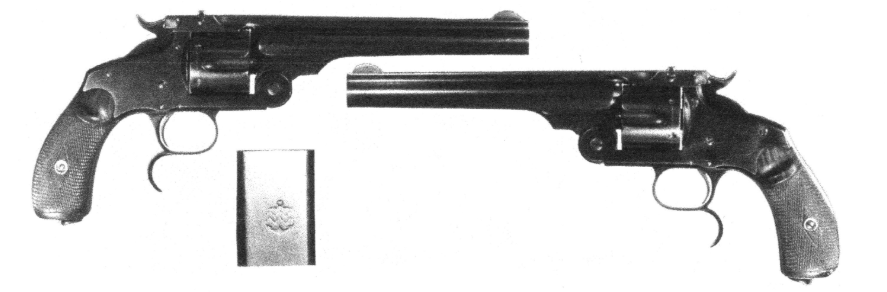

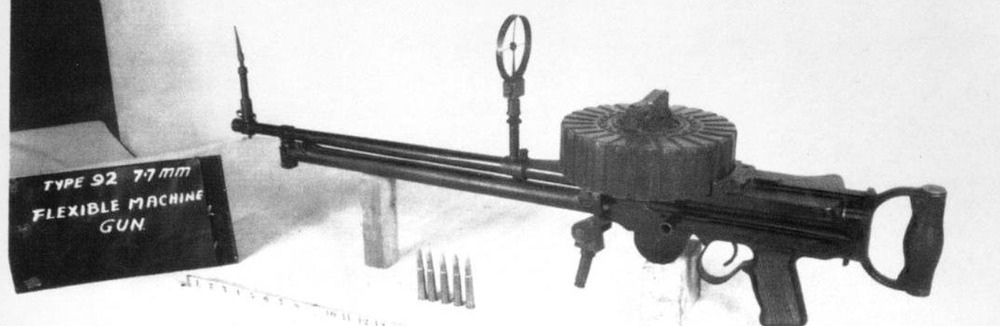

In 1931 and 1932, the Japanese negotiated production rights with BSA, ultimately securing the necessary equipment and tooling for their own production program. In 1932 Japan officially adopted the aircraft and ground-based Lewis gun models under the designation Type 92.

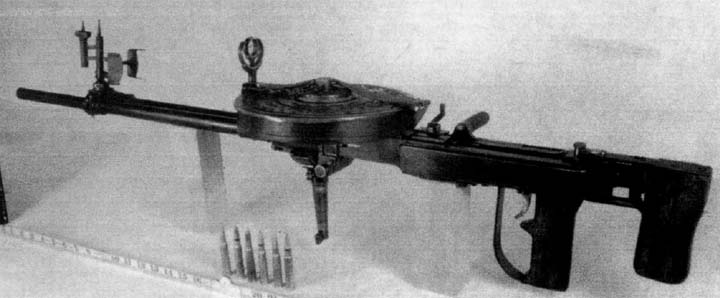

Type 92 Aircraft Model with 97-Rounds disk and “shovel” stock.

The Type 92 differed in several respects from the original Lewis guns supplied by BSA. One of the main distinguishing features was the extended trigger guard. The cocking handle was located only on the left side. The gas regulator on the Type 92 had only one gas port, resulting in a stable rate of fire of 700 rounds per minute (According to American data, 600 rounds per minute.).

| Specification |

Type 92 |

| Rate of Fire |

700 rpm (600 rpm per US data) |

| Initial Velocity |

740 m/s |

| Cartridge |

7.7x56 mm |

| Ammo Capacity |

47 and 97 Rounds |

| Weight (Empty) |

11,79 |

| Weight (Loaded 47) |

1.87 kg |

| Weight (Loaded 97) |

3.99 kg |

| Fire Mode |

Automatic |

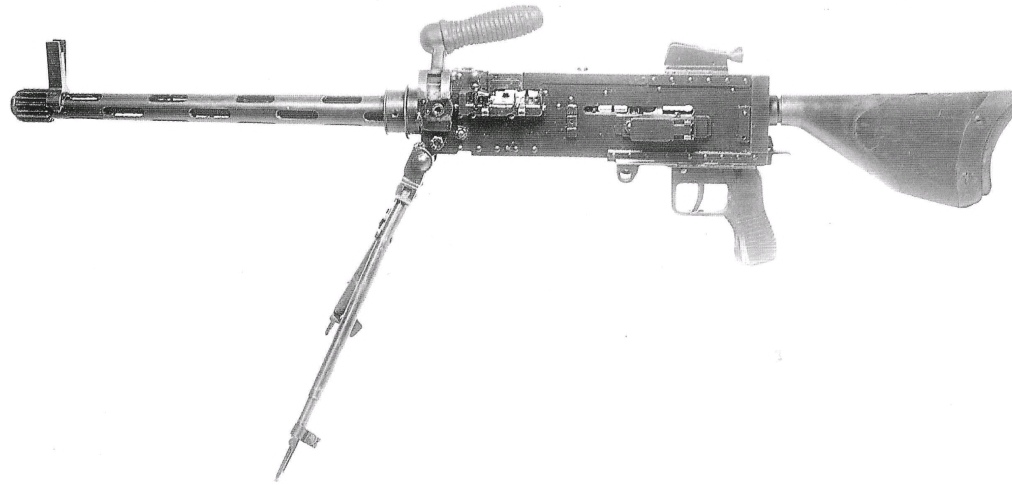

Type 92 Converted For Land Use, note the rifle stock.

More photos

Type 92 Converted For Land Use, note the rifle stock.

Type 92 Converted For Land Use, note the rifle stock.

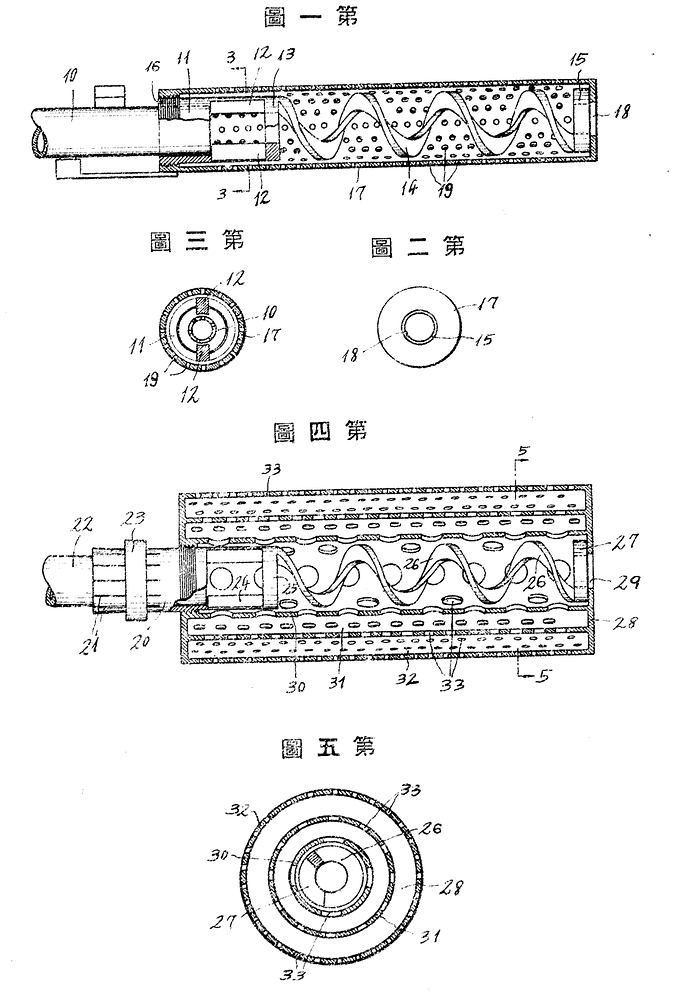

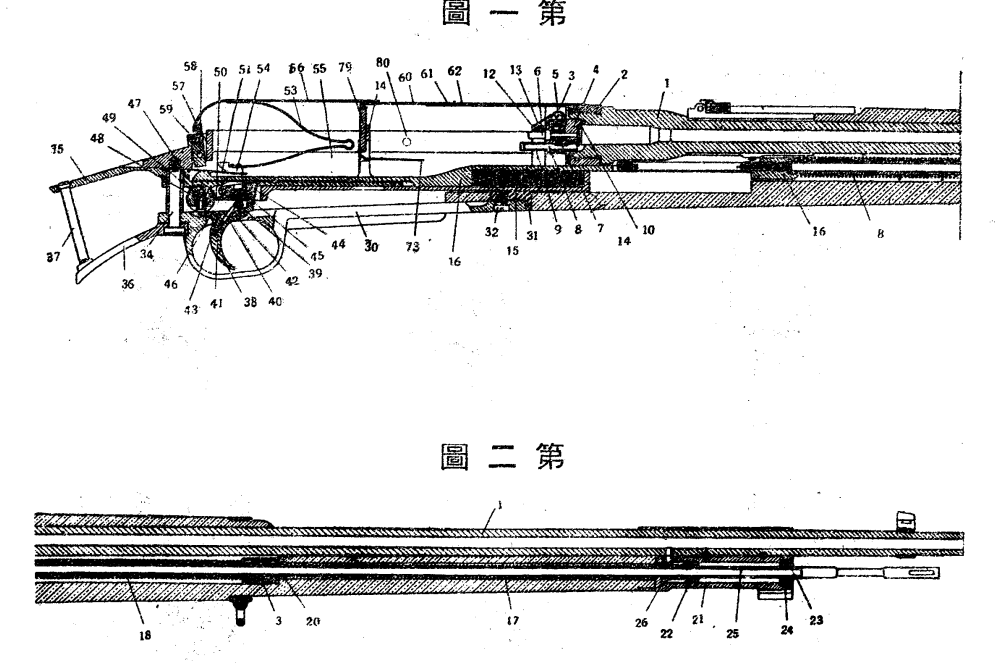

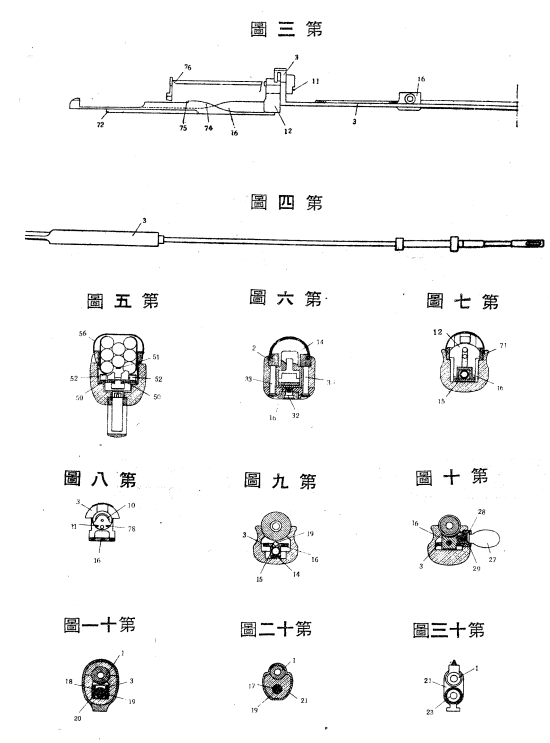

Development of the Type 96

Due to the Type 11’s overly complex hopper system and its susceptibility to jamming from dirt, the Army Technical Headquarters convened in April 1932 to design a replacement. By June, they established 15 design guidelines for a new LMG. The primary goals were reliability, simplicity, the adoption of a box magazine, a pistol grip, and a unified barrel-and-radiator assembly to allow for quick barrel changes under fire.

Four manufacturers were invited to submit prototypes: the Army Arsenal, Tokyo Gas Electric, Nippon Special Steel, and the Nambu Rifle Manufacturing Company. The design requirements were strict:

- Weight: Under 9 kg.

- Caliber: 6.5mm.

- Rate of Fire: Approximately 500 rounds per minute.

- Muzzle Velocity: At least 730 m/s.

After initial testing at the Koishikawa Arsenal in April 1933, the designs from the Army Arsenal and Nambu were selected for further development.

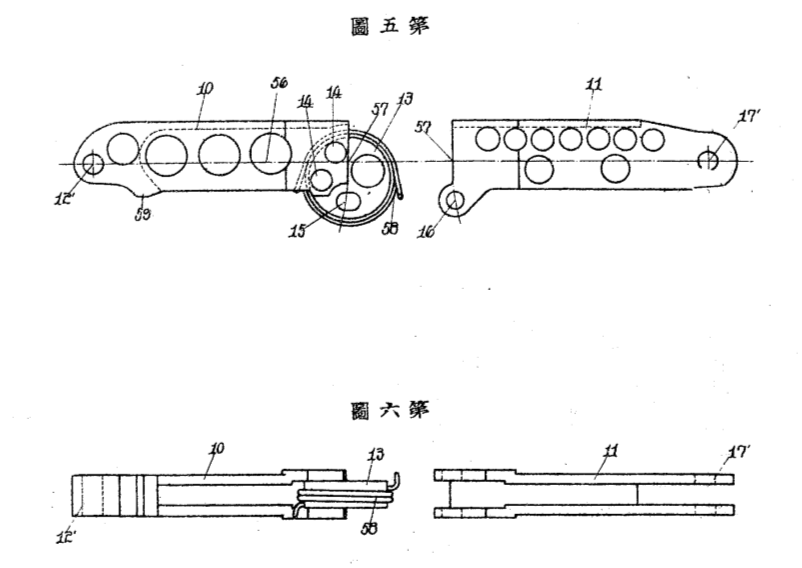

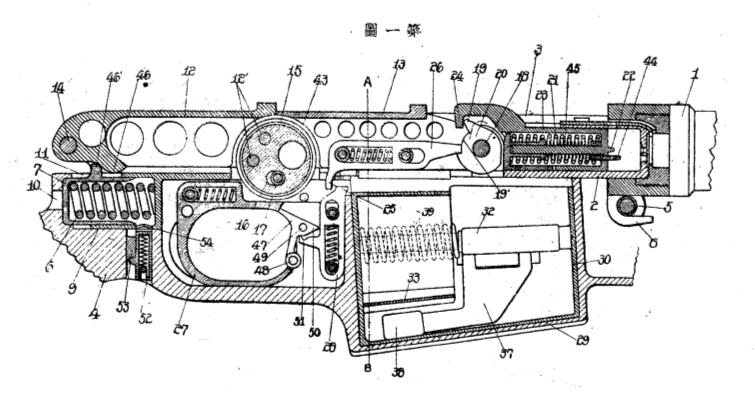

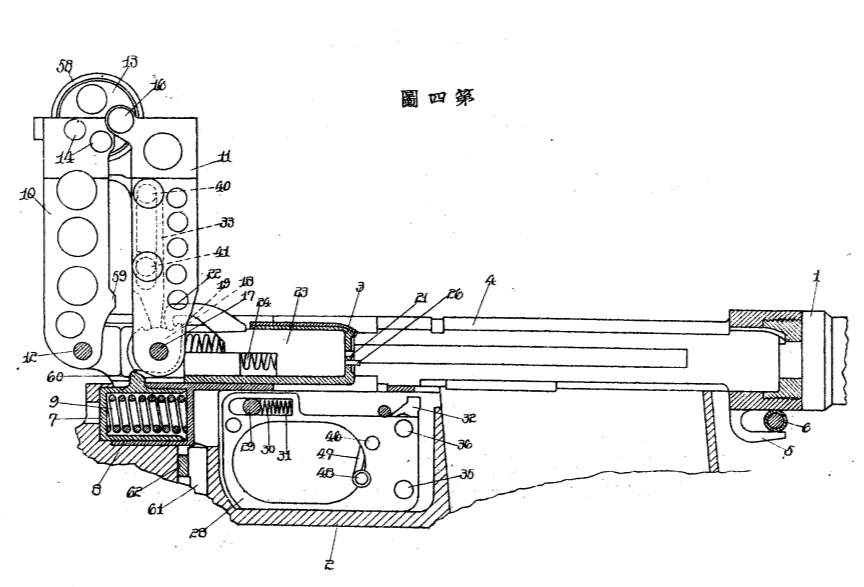

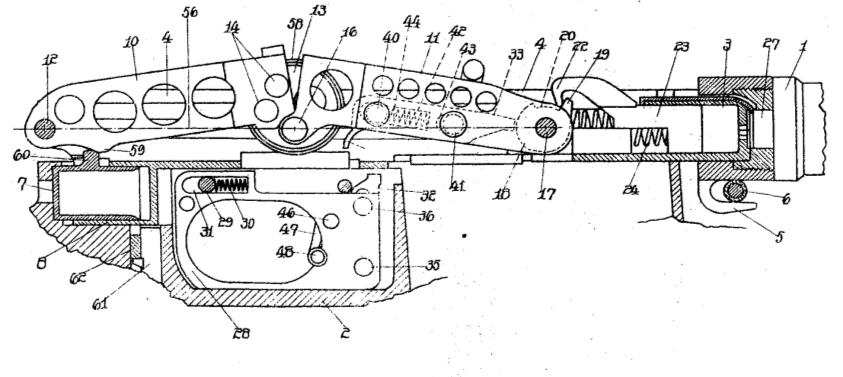

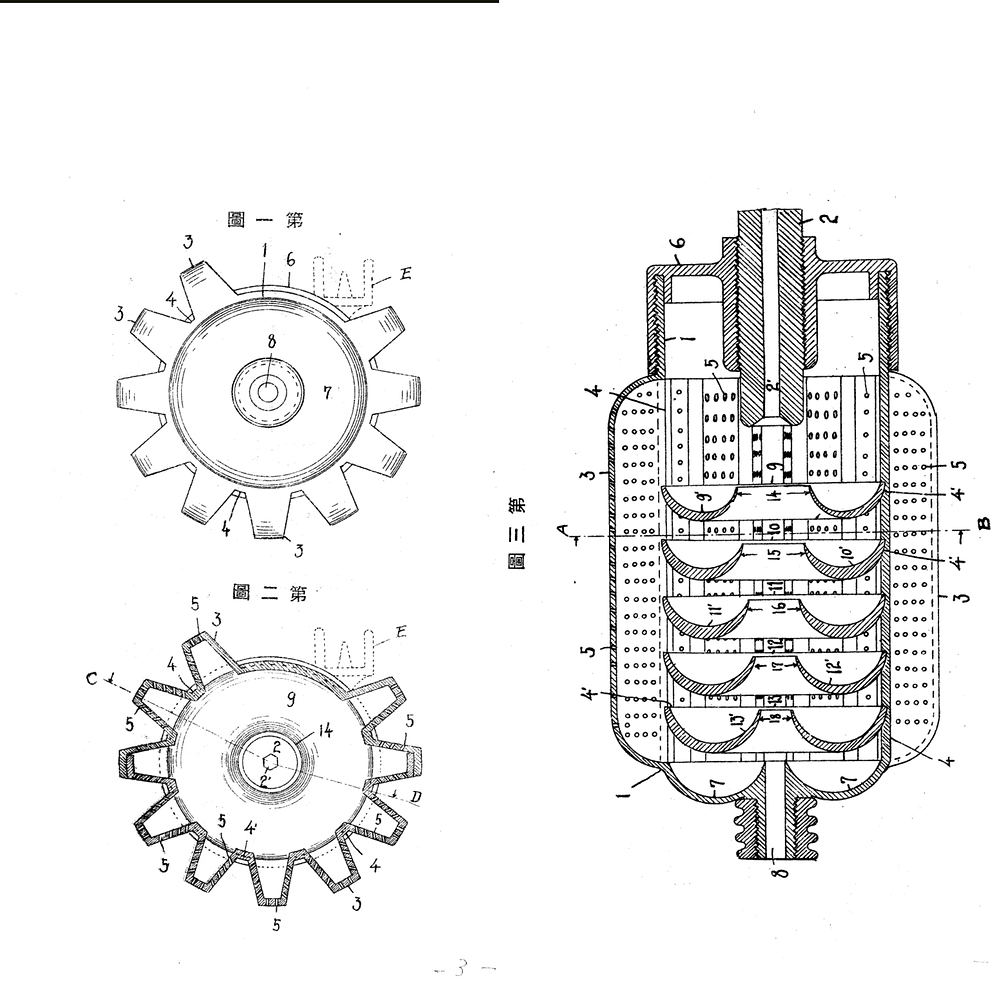

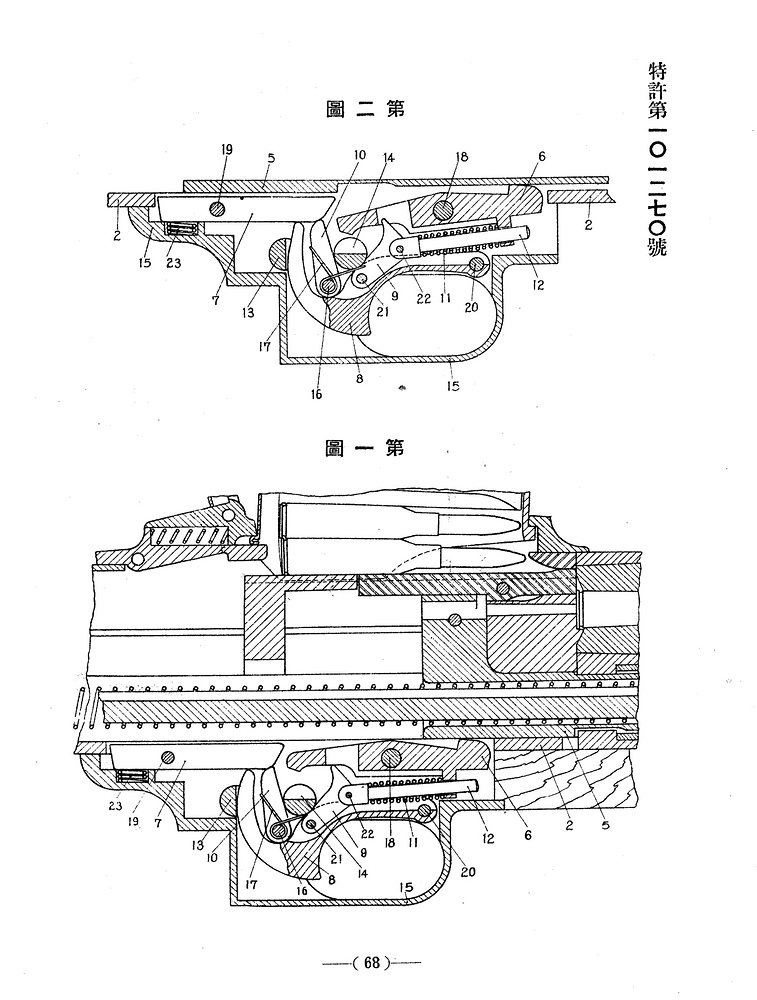

Among the competing designs, the submission from Nippon Special Steel, developed by Dr. Masaya Kawamura, stood out for its highly sophisticated engineering. Unlike its rivals, Kawamura’s prototype utilized a unique locking block system where two locking lugs (flappers) were forced into recesses in the receiver by the firing pin (striker) to lock the action. A distinctive feature of its fire control group was its hybrid operation: the weapon fired from a closed bolt in semi-automatic mode for increased precision, but switched to an open bolt during fully automatic fire to prevent cook-offs. Despite its technical brilliance, the design was dropped from the competition in 1935, primarily because its staggering cyclic rate of 1,200 rounds per minute was deemed excessive for a light machine gun and led to reliability issues. However, the project was far from a failure; Kawamura’s locking mechanism proved so robust that it was later scaled up and used in the famous 20mm and 30mm (Type 5) aircraft cannons that armed legendary fighters like the Zero, Raiden, and Shiden.

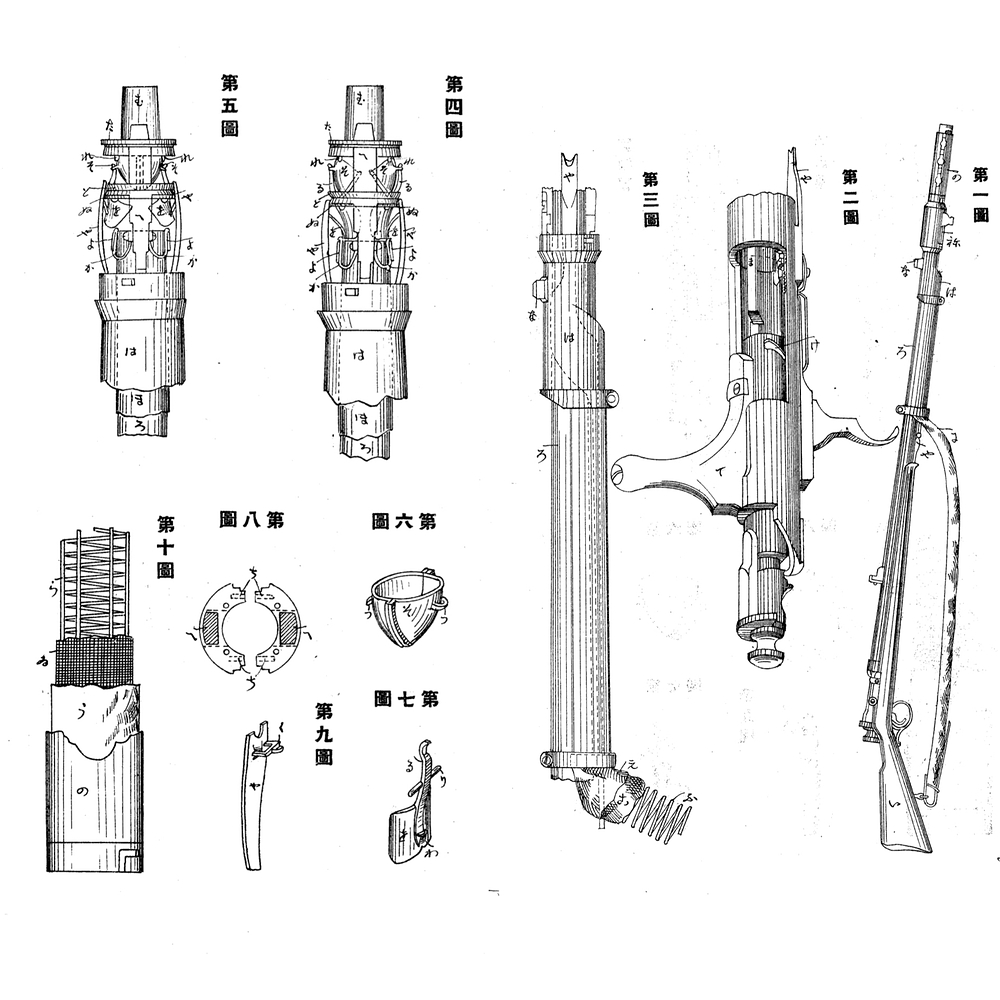

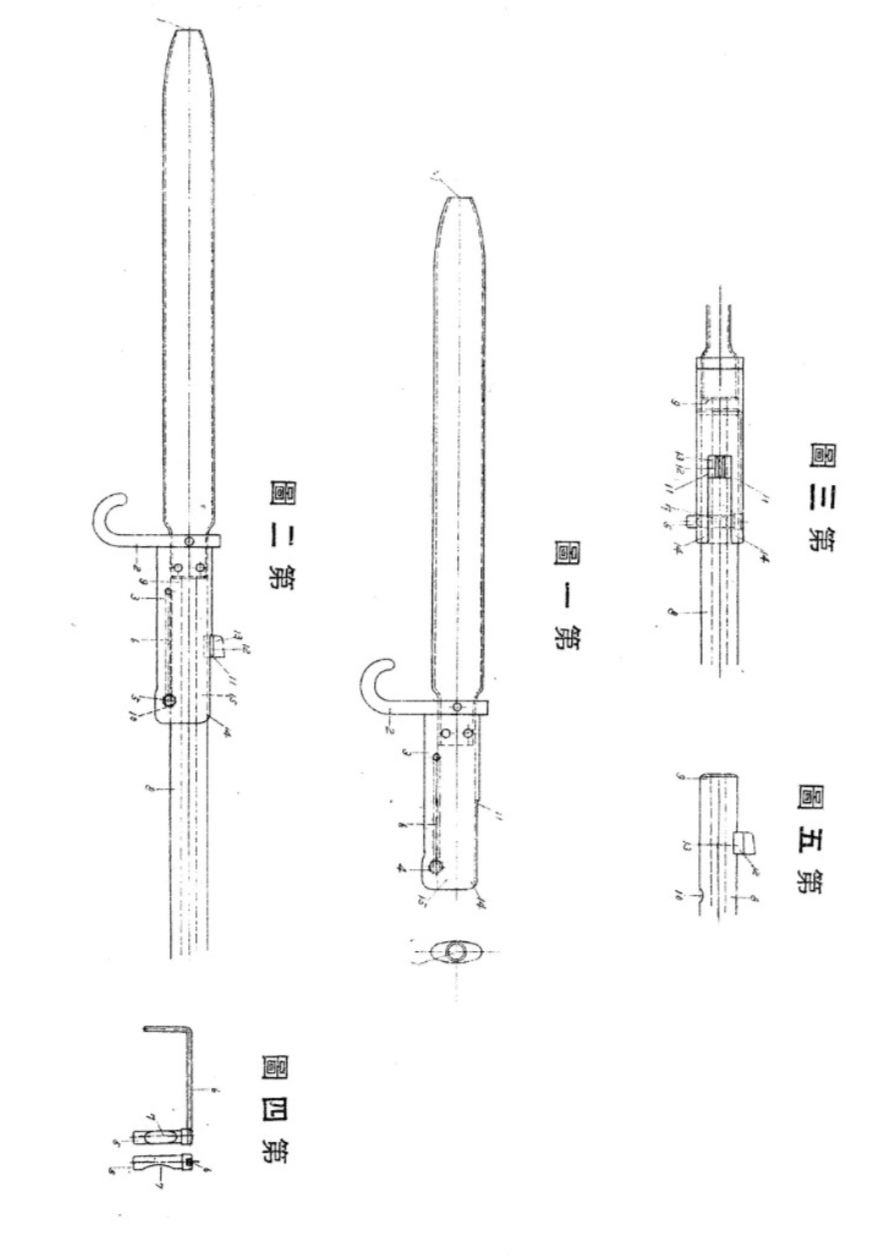

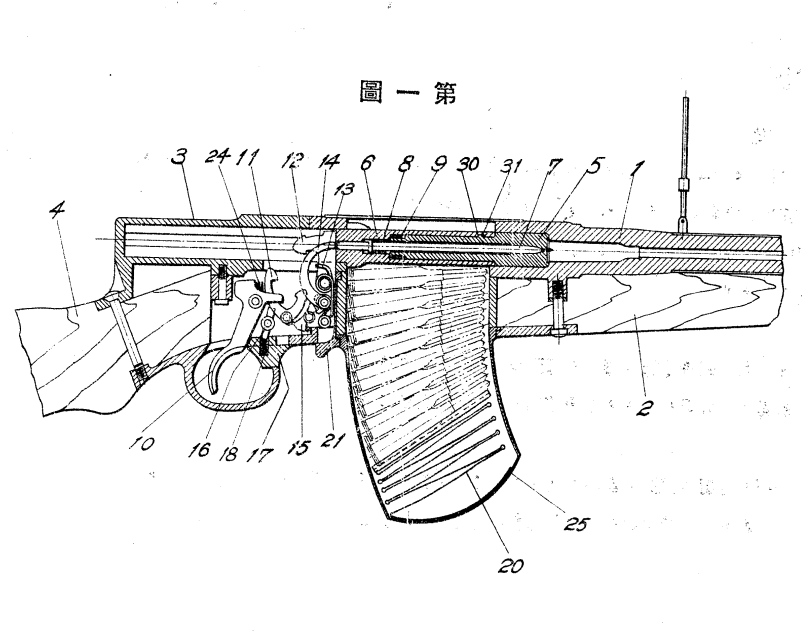

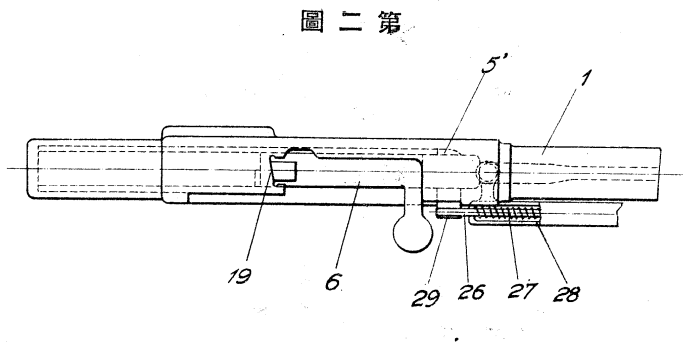

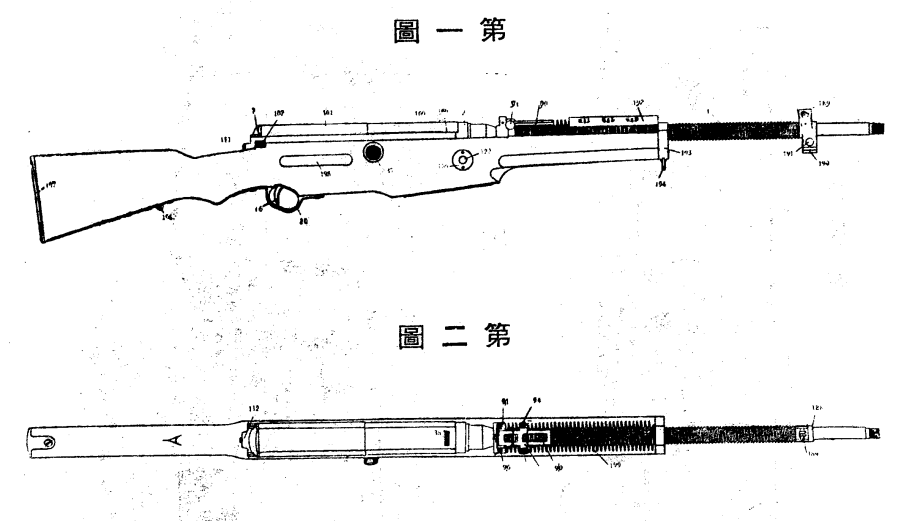

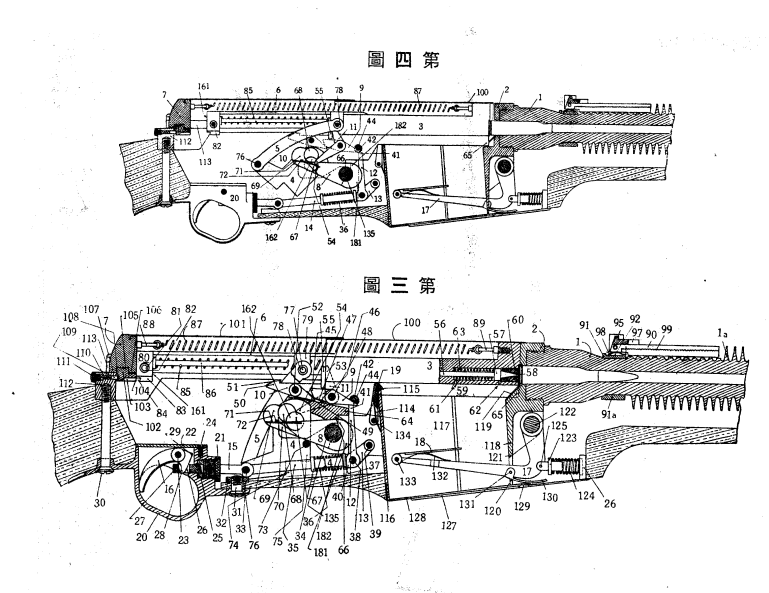

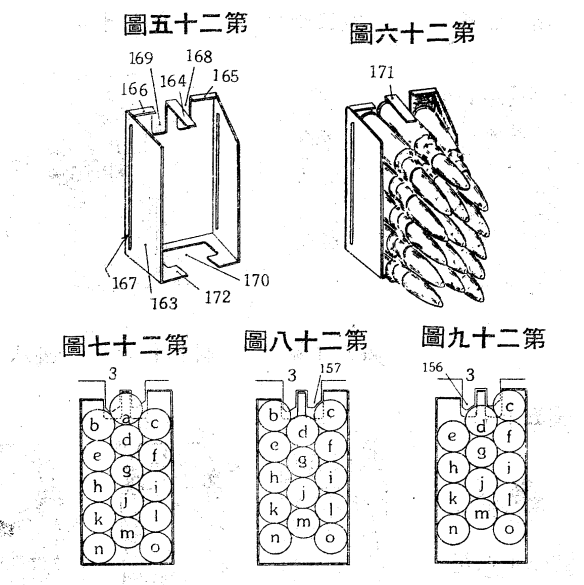

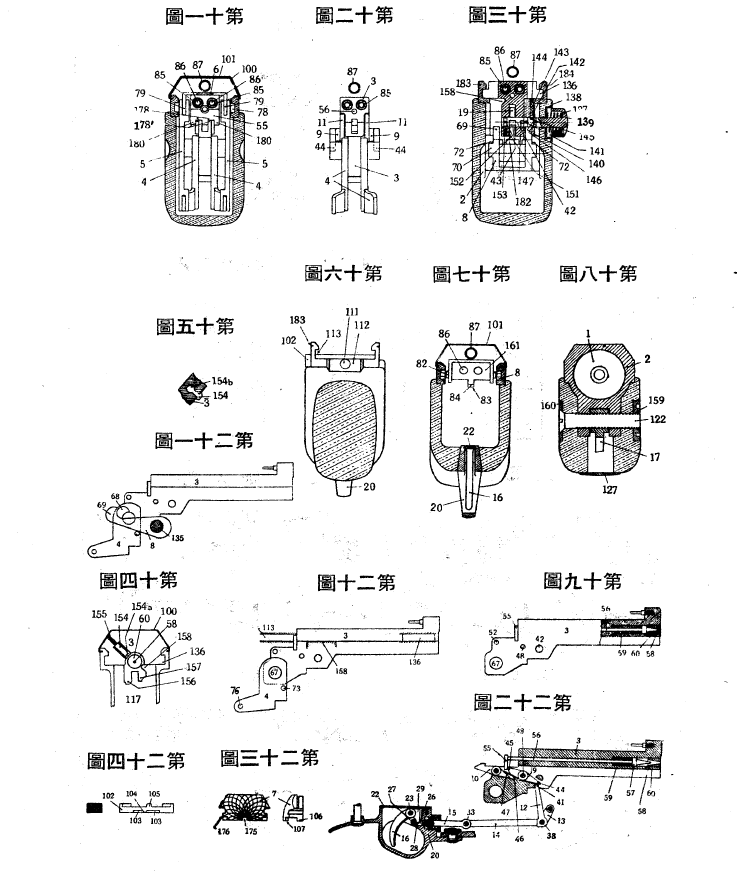

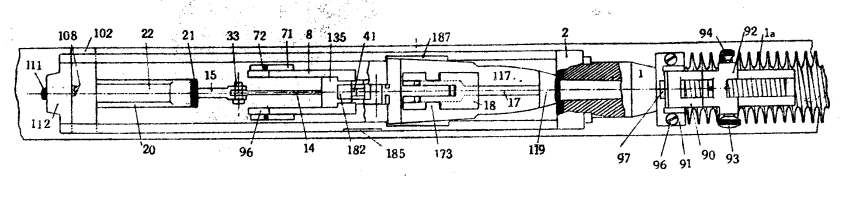

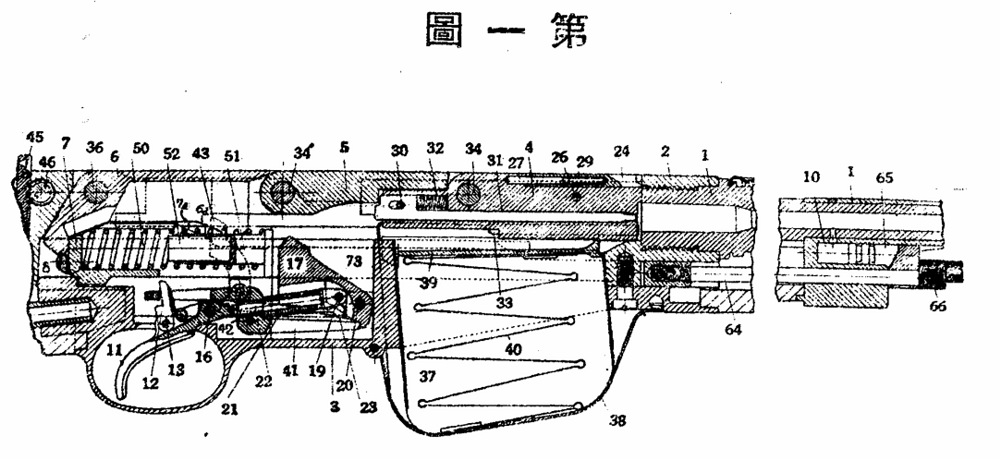

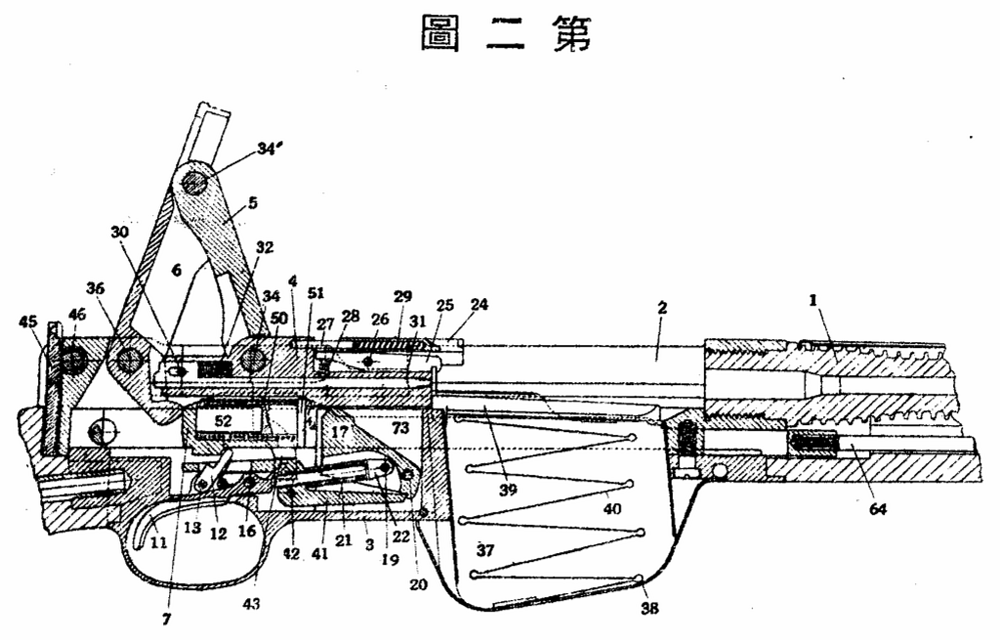

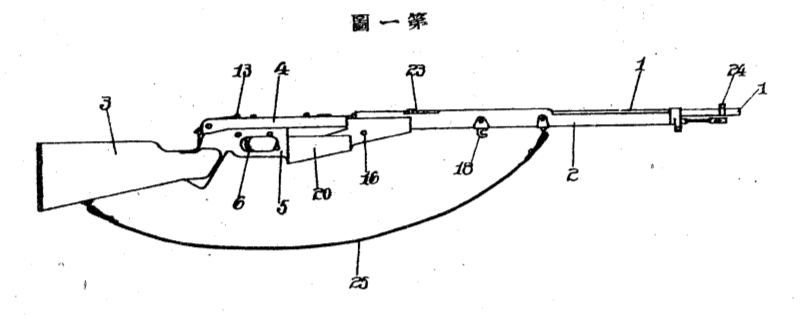

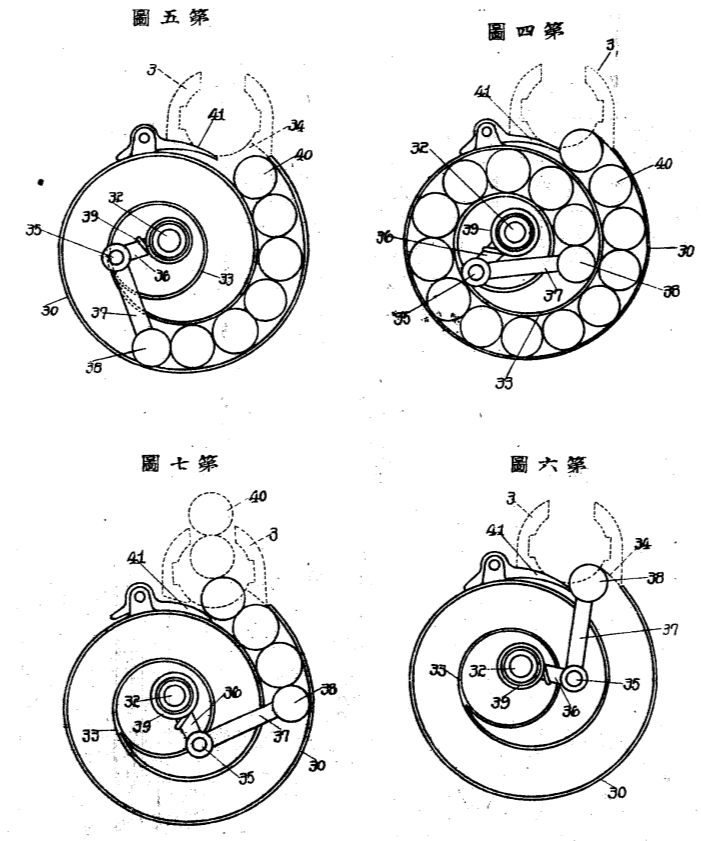

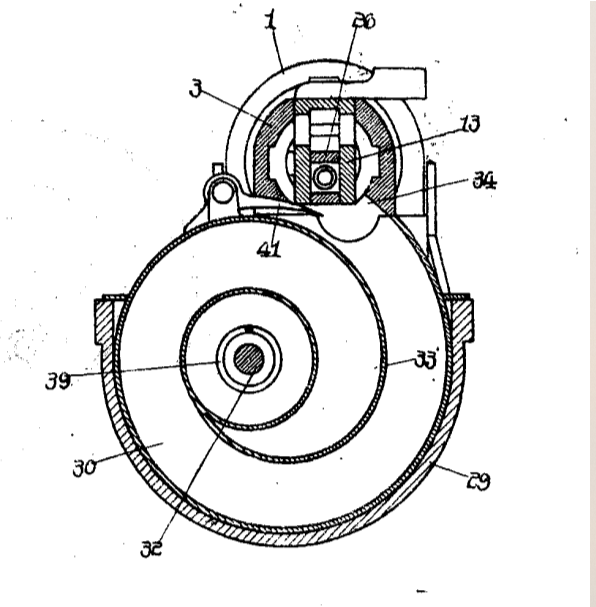

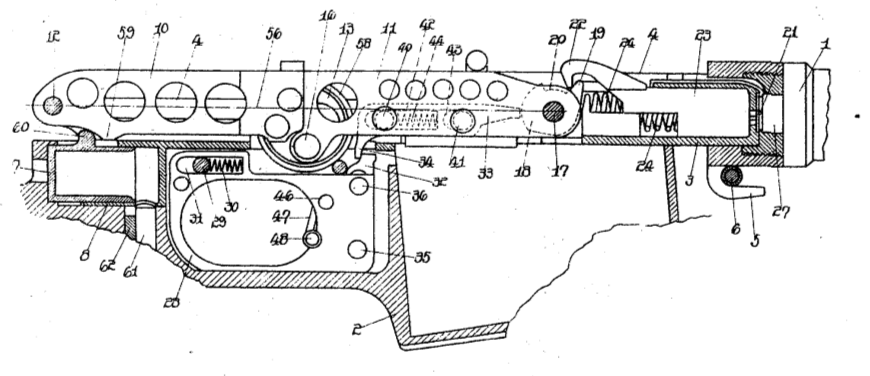

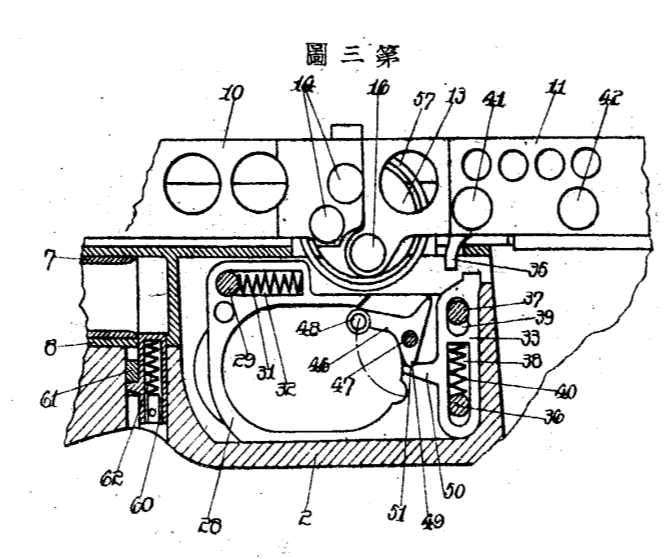

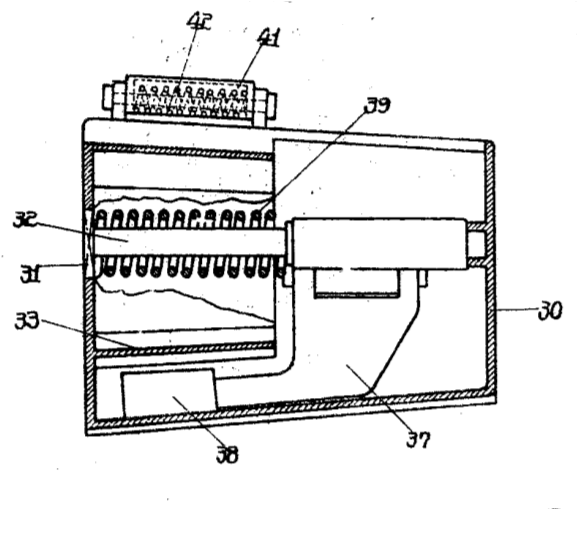

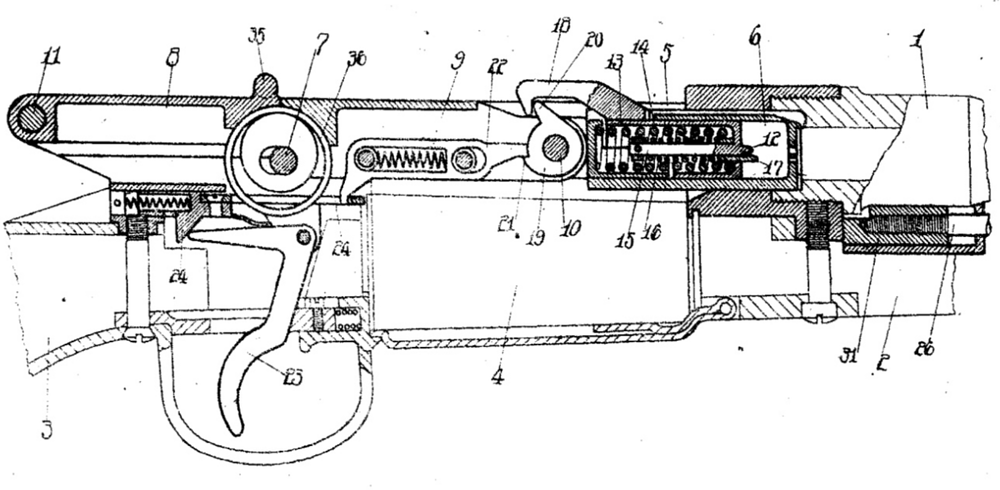

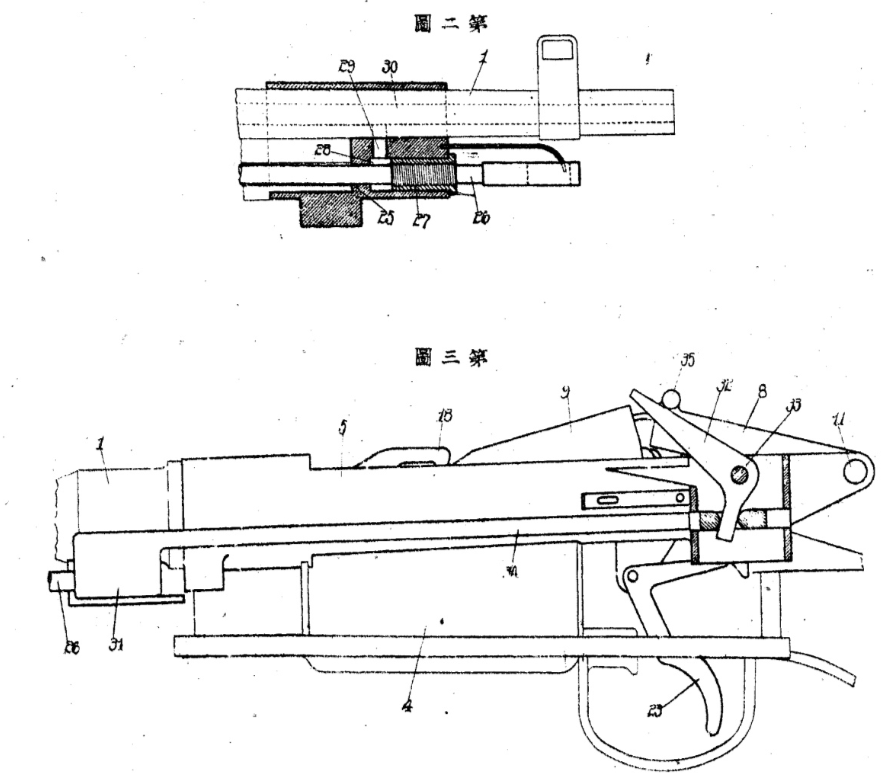

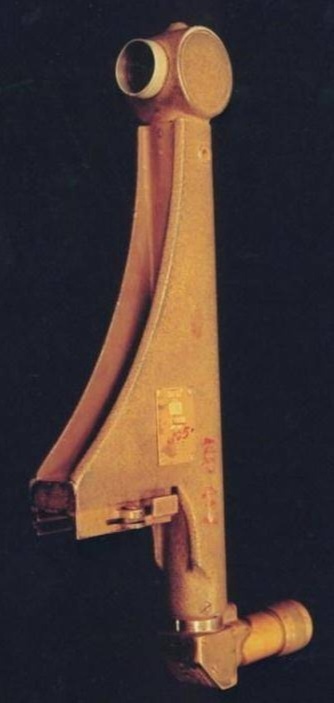

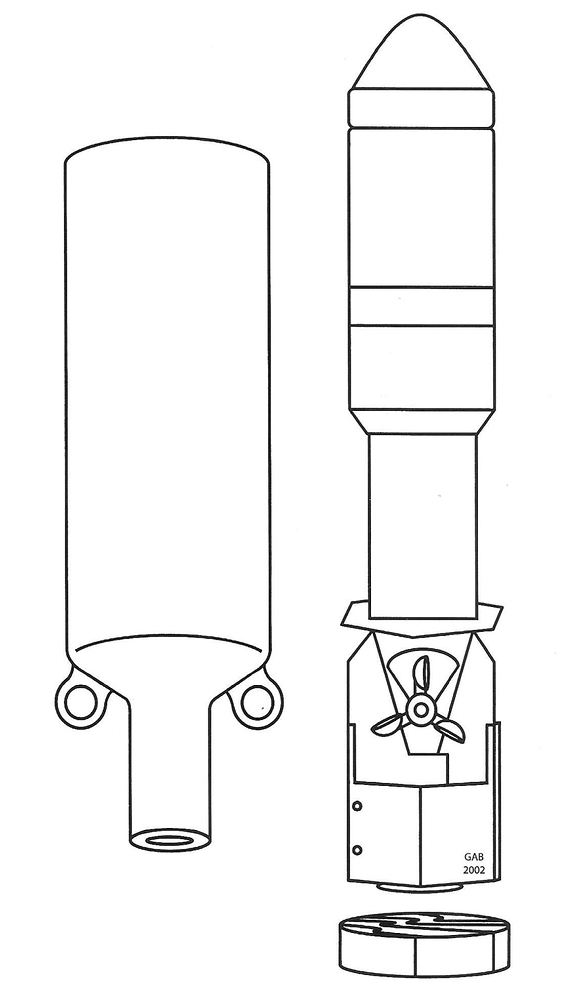

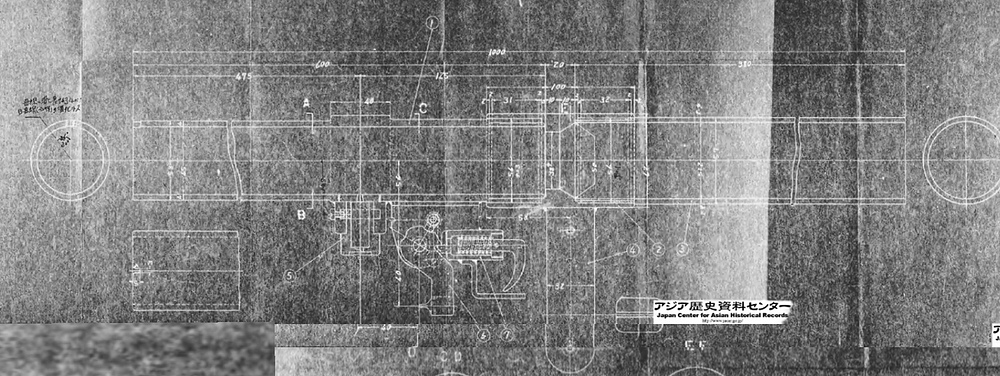

Patent drawing of a machine gun by Nippon Special Steel.

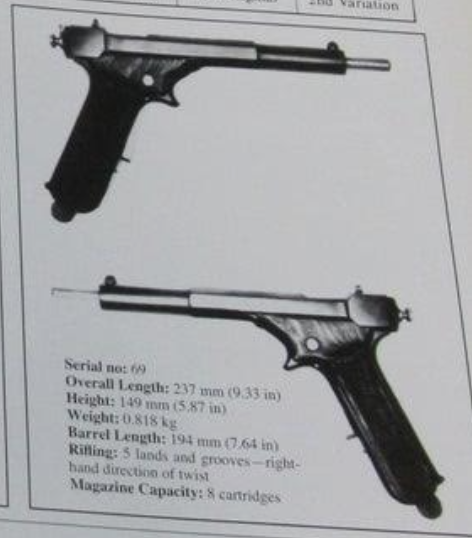

Second-stage prototypes were completed by November 1933. These underwent grueling evaluations, including winter trials in North Manchuria and practical testing at the Army Infantry and Cavalry Schools. While accuracy matched the Type 11, magazine feed issues remained a point of focus.

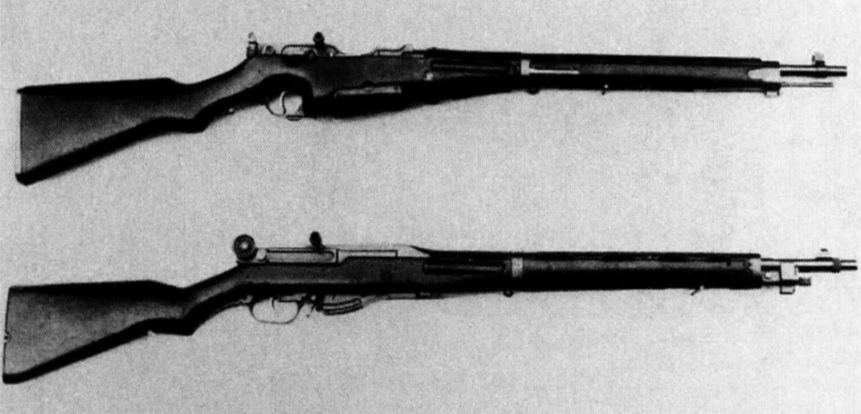

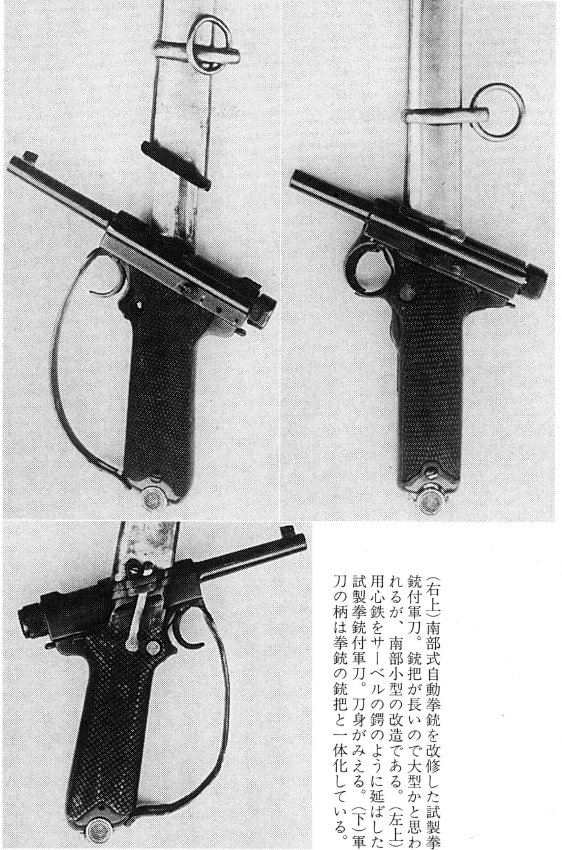

In May 1934, the Technical Headquarters ordered third-stage prototypes to finalize the design. Two distinct models were produced:

- Model Ko: A hybrid design built by Nambu that combined the best features of previous prototypes.

- Model Otsu: An Arsenal-built design featuring a downward shell ejection system.

Model Ko machine gun from the Nambu factory. Note the absence of a bayonet lug.

Model Otsu machine gun from the Arsenal. It is a copy of the Czech ZB-26.

| Specification |

Model Ko |

Model Otsu |

| Total Length |

1,150 mm |

1,150 mm |

| Barrel Length |

550 mm |

550 mm |

| Total Weight |

7.980 kg |

9.000 kg |

| Magazine Weight (Empty) |

0.510 kg |

0.450 kg |

| Magazine Weight (Full) |

1.140 kg |

1.080 kg |

| Ammunition Capacity |

30 rounds |

30 rounds |

| Muzzle Velocity |

746.4 m/s |

743.0 m/s |

| Cyclic Rate of Fire |

500–600 rpm |

530–650 rpm |

| Ejection Direction |

Bottom-Right |

Downward |

More photos

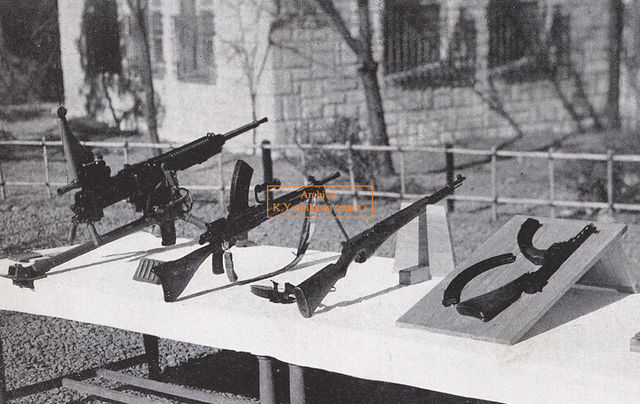

An exhibition organized during the Emperor’s visit to the Army Technical Headquarters in 1935. Note the Model Ko machine gun.

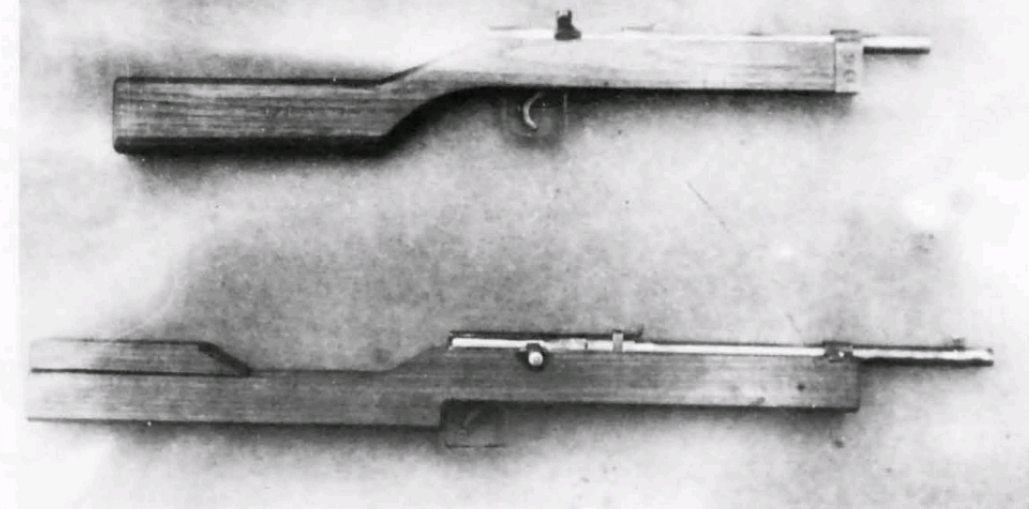

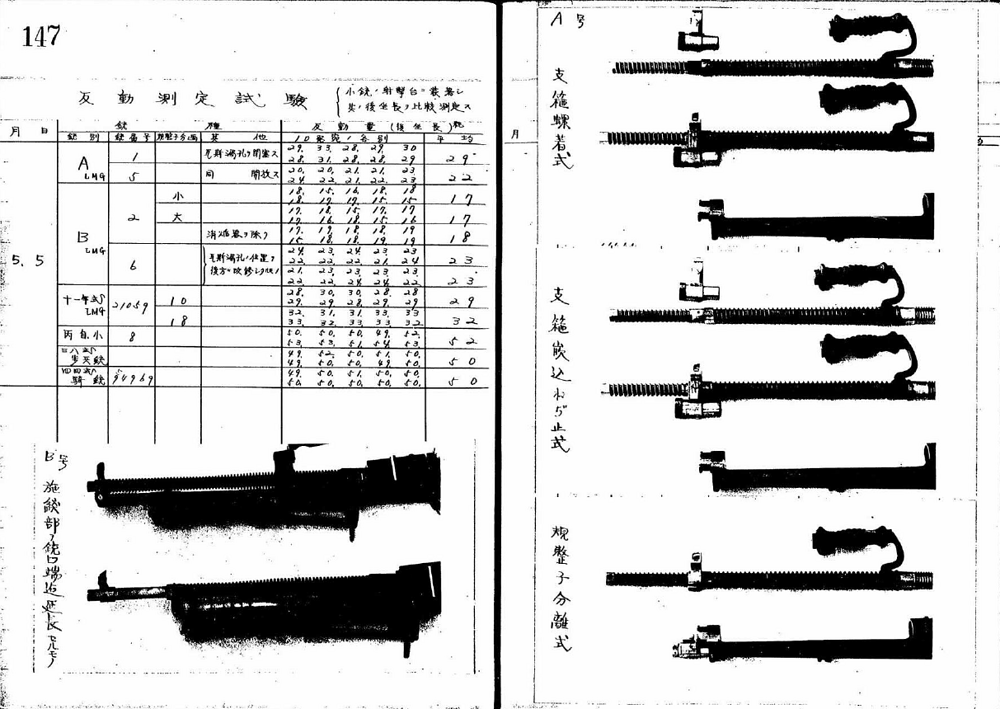

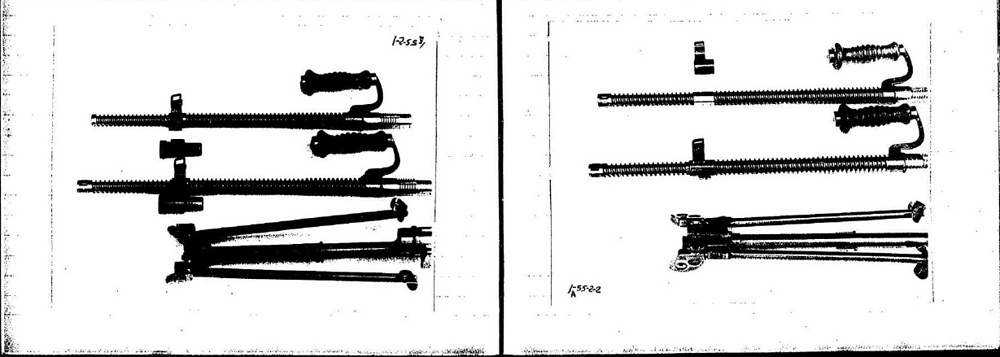

Barrels of the Model Ko and Model Otsu machine guns.

Barrels of the Model Ko machine gun.

Following extensive accuracy tests at the Futtsu range and final winter trials, Model Ko was officially selected for adoption in August 1935. After final modifications were completed in late 1935, the weapon underwent its last practical tests in January 1936 and was officially designated as the “Experimental Type 96 Light Machine Gun.”

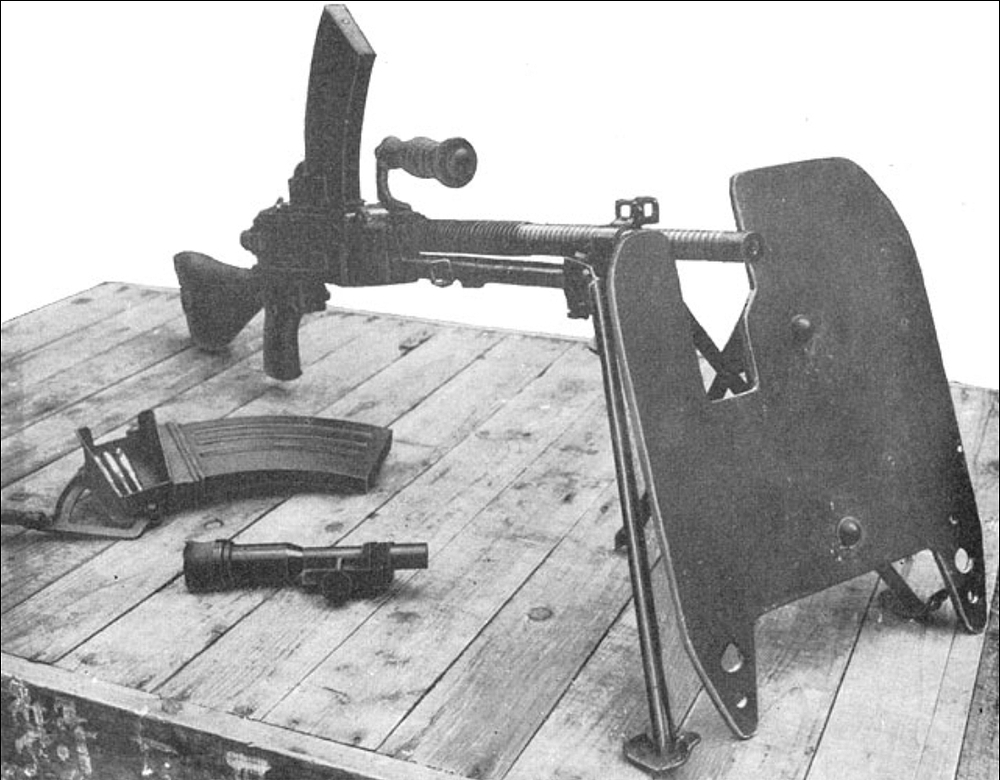

Type 96 machine gun with a shield and an optical sight.

| Specification |

Type 96 |

| Caliber |

6.5 mm |

| Overall Length |

1.048 m |

| Total Weight |

8.7 kg |

| Muzzle Velocity |

735 m/s |

| Maximum Range |

3500 m |

| Rate of Fire |

550 rpm |

| Feed System |

Box magazine |

| Magazine Capacity |

30 rounds |

| Bullet Weight |

9 g |

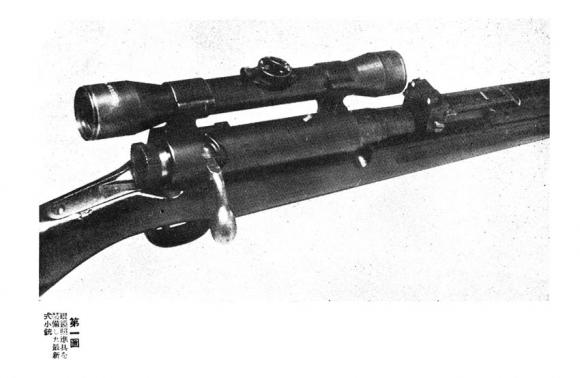

To enhance accuracy against ground targets (up to 500 m) and aerial threats, the Type 96 machine gun was equipped with a detachable 2.5×20 mm optical sight. Due to the top-mounted magazine, the sight was offset to the right, allowing it to be used simultaneously with the iron sights. The optic lacked external adjustment knobs; all corrections for range (up to 1,600 m), windage, and aircraft speed were made using a complex internal reticle. Only 10,000 units were produced, so not all gun crews were equipped with these sights.

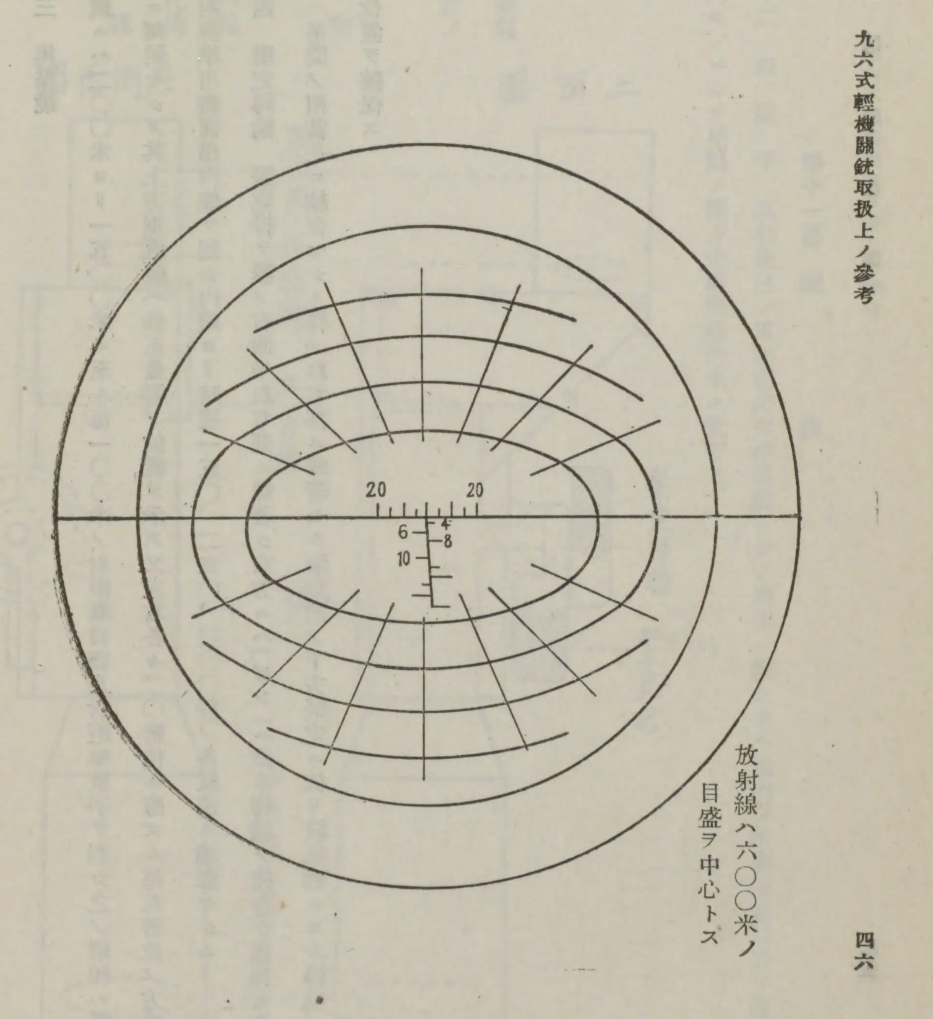

Reticle of the Type 96 optical sight.

ZB-26 in Japan

Czech data show that 32,272 ZB-26 machine guns were delivered to China between 1927 and 1939. Of these, 17,163 were purchased by the national government from 1937 to 1939, with the final batch of 100 units shipped in April 1939. Successful local imitation began at the Dagu Shipyard in 1927, after which various arsenals followed suit. In 1934, the Ordnance Industry Directorate adopted the Czech-style design as the standard light machine gun, and by the end of the Second Sino-Japanese War, it had become the most significant light machine gun in the country’s history.

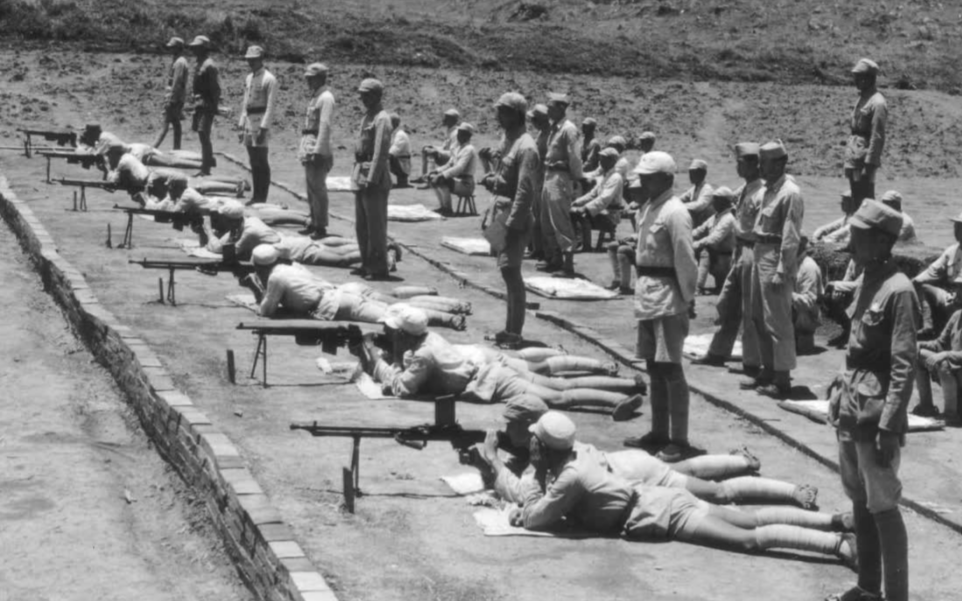

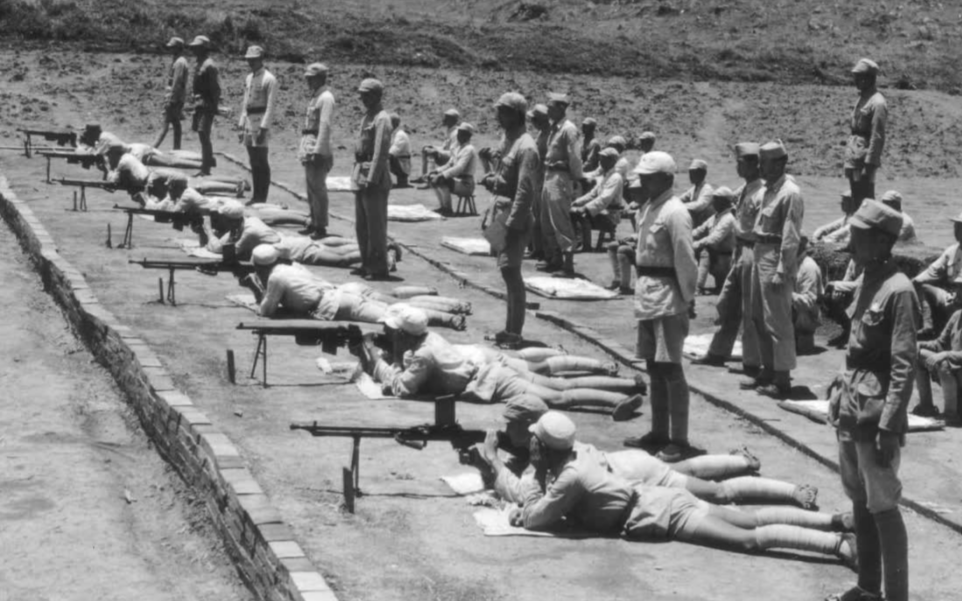

Chinese soldiers practice shooting with the ZB-26

In 1938, the Zhejiang Iron and Steel Works also began producing an improved Light Machine Gun in the Czech style, called the Type 77, with a monthly output of 60 units. The Light Machine Gun produced by the Zhejiang Iron and Steel Works features a square rear pin, a magazine moved to the right side, a round bolt, a rifle-like rear sight on top, and a gas adjustment device.

Type 77 Light Machine Gun.

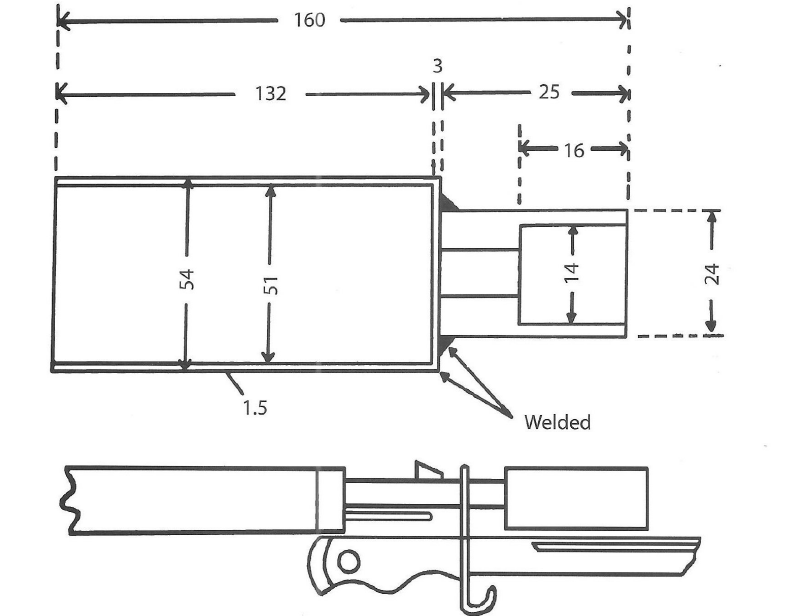

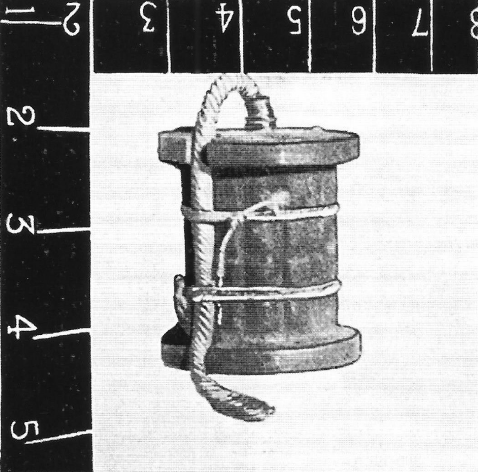

The standard 20-round magazines of ZB-26 Light Machine Gun were often insufficient, so there are reports of 30-Round Magazines and 40-Round Magazines, presumably welded from two standard magazines. No specific information about the machine guns could be found.

Comparison of 20-round and 30-round magazine in terms of manufacturing quality, one can speak of serial production.

More photos

Chinese soldier with the ZB-26 with 30-round magazine, also note the non-standard support for the Light Machine Gun.

Chinese Soldier with ZB-26 with 30-Round Magazine.

ZB-26 with a presumably 40-round magazine, made by welding two standard magazines.

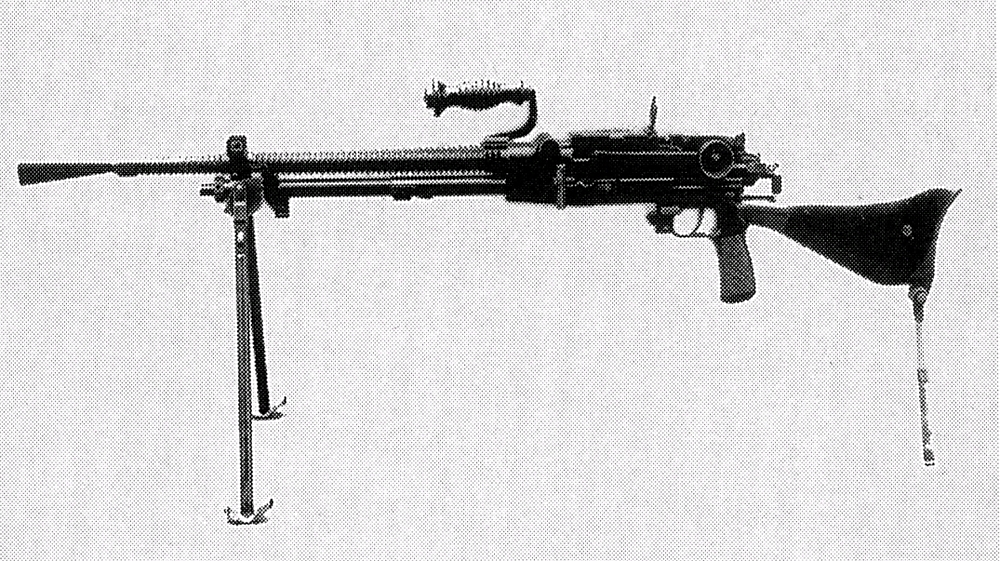

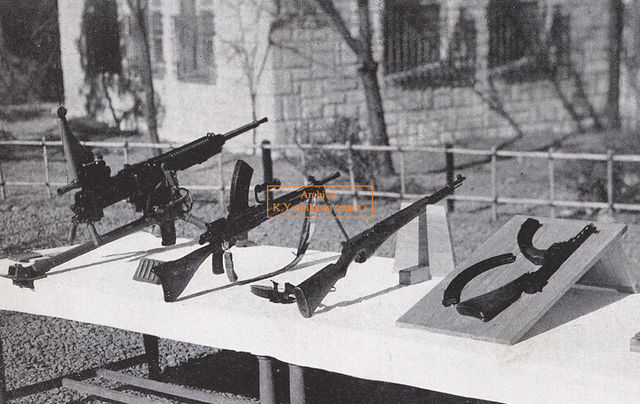

The ZB-26 gained widespread popularity among the Japanese military when they captured large numbers of them during the Second Sino-Japanese War. In Japan the Light Machine Gun was Designated Type Chi Compared to the Type 11 machine gun, the Czech ZB-26 was more reliable and had a more powerful cartridge.

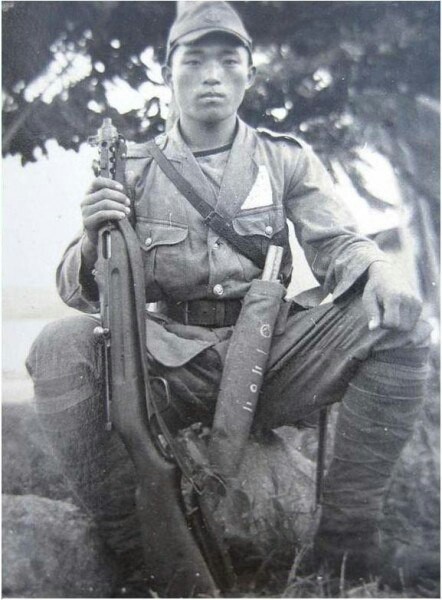

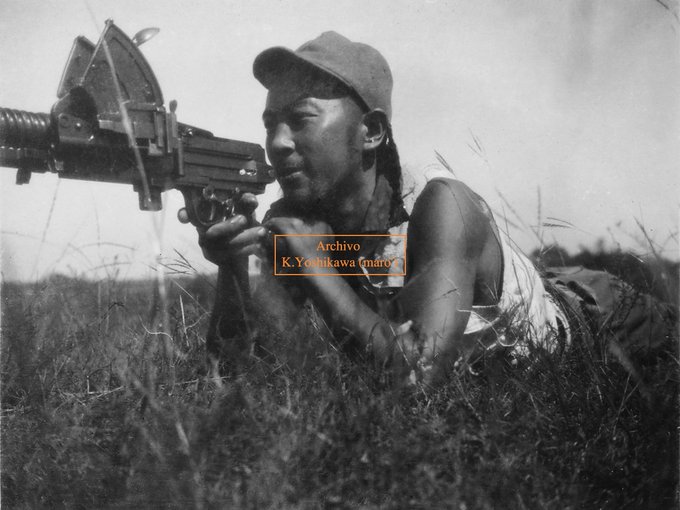

Japanese Soldiers with Type Chi Light Machine Guns.

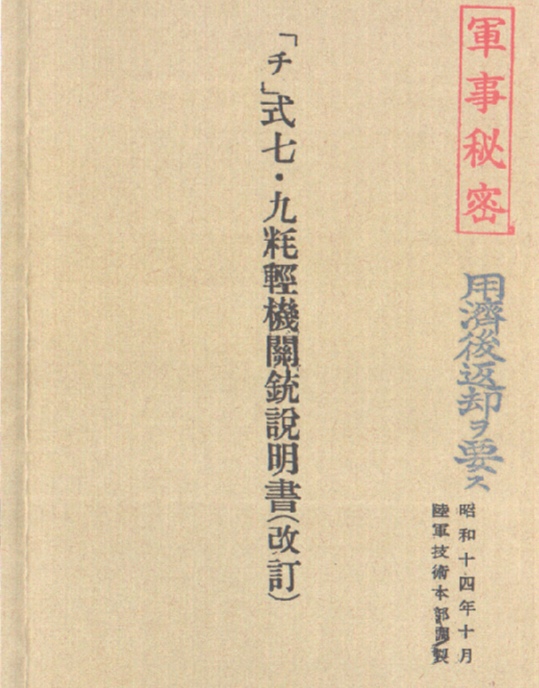

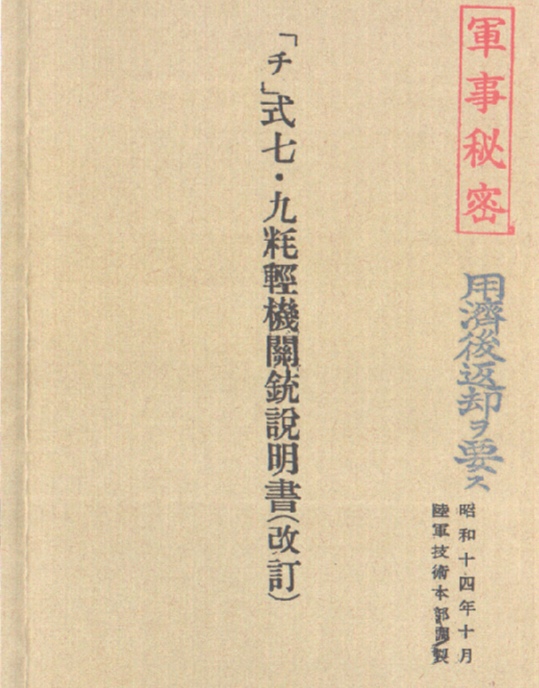

To equip airfield security units, the Imperial Japanese Army purchased 2,310 ZB-26 light machine guns from Czechoslovakia in the late 1930s. The first order for 2,000 units was sent on January 10, 1939, followed by a final order of 150 on October 17, 1939. Japan adopted the weapon semi-officially as the “Type Chi 7.9mm Light Machine Gun,” producing standard Type 98 ammunition for it in local arsenals and compiling an official manual for the Type Chi in 1939.

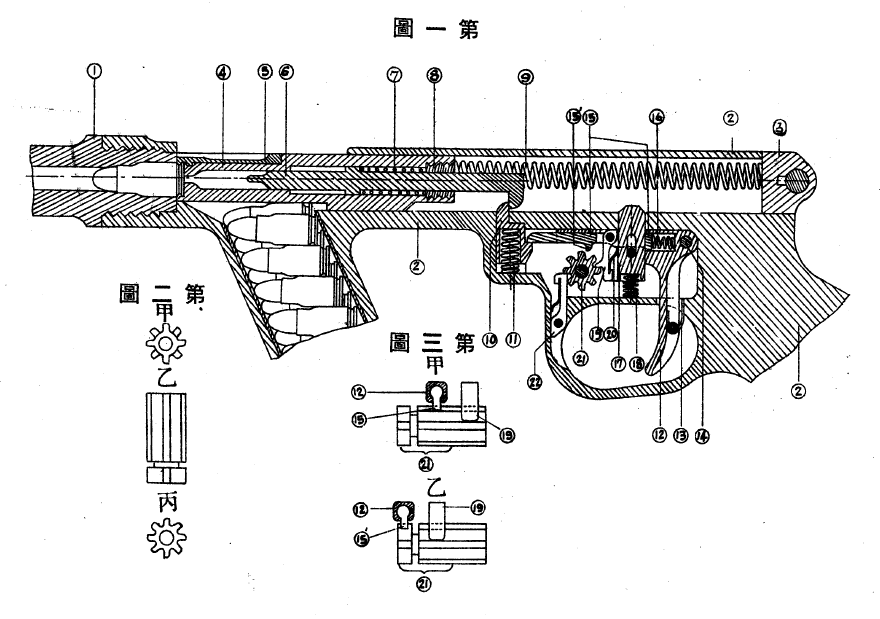

Cover of the Type Chi machine gun manual.

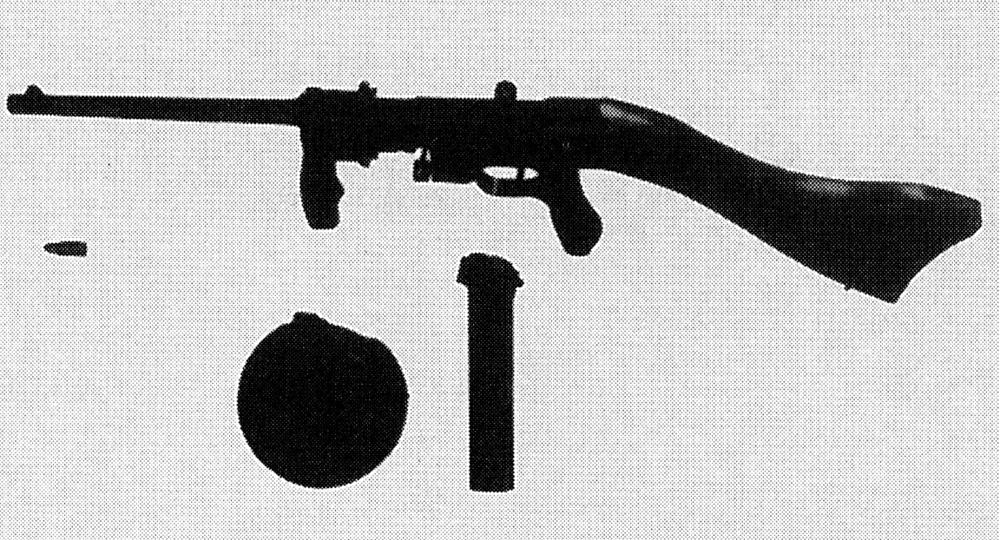

The Taiyuan Arsenal in Shanxi Province produced copies of the ZB-26 and Thompson submachine guns. In 1939, under Japanese occupation, Thompson production was discontinued while ZB-26 manufacturing was restored to its previous volume to supply Japanese and Manchurian forces. Some parts and tooling were transferred to the Hoten Arsenal (formerly Mukden) to establish serial production of unlicensed ZB-26 copies, with total output estimated at 10,000 units. Around 1940, a version chambered for the Japanese 6.5x50mmSR cartridge was developed; this variant lacked official kanji markings and featured a modified 30-round Type 96 magazine, a 603mm barrel, and a total length of 1,162mm, matching the dimensions of the original prototypes. Unfortunately, it is impossible to say anything about the project’s goals or the scale of production, as the arsenal documentation was destroyed by personnel.

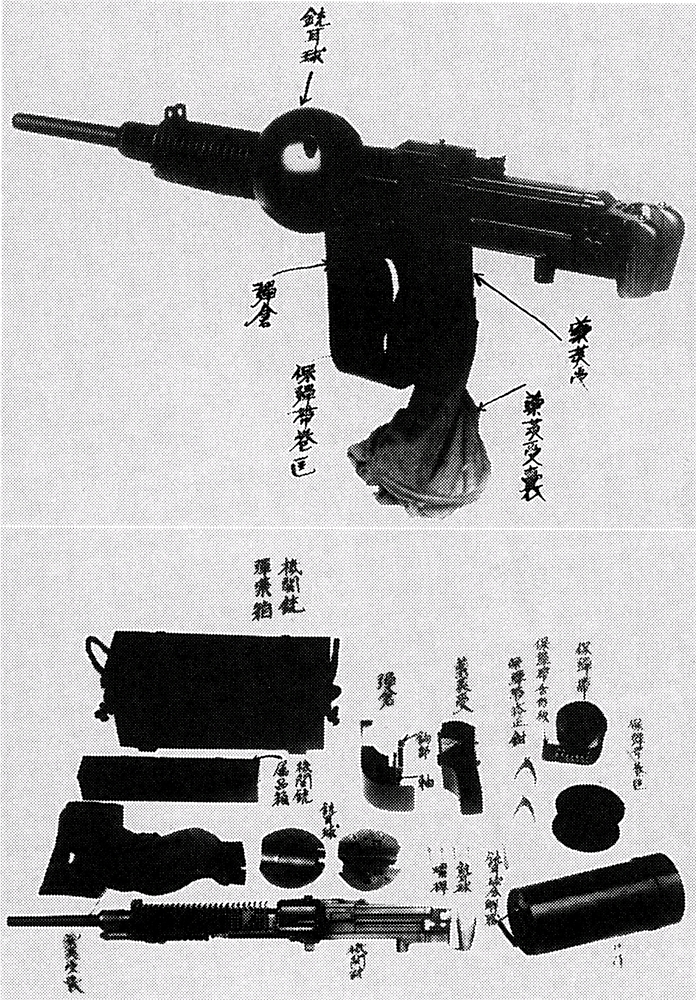

ZB-26 6.5mm Caliber Light Machine Gun of Mukden Arsenal.

More photos

American Soldier with a ZB-26 6.5mm with the Type 96 Magazine on the island of New Britain, territory of New Guinea, February 13, 1944.

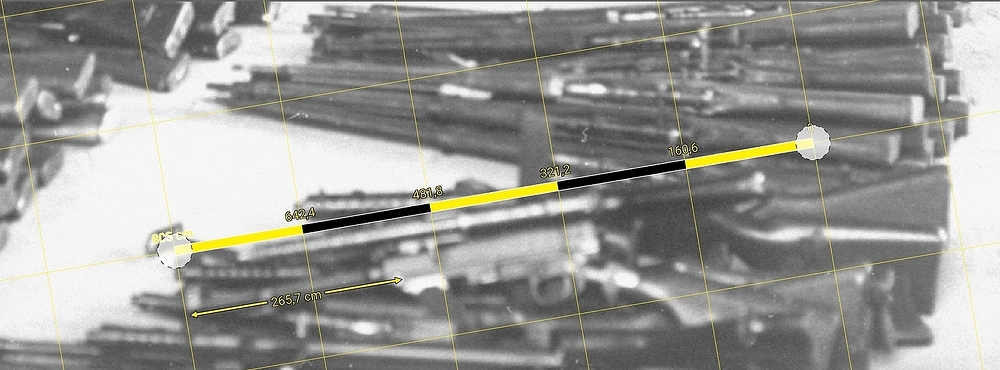

Magazine and loading machine for ZB 26 6.5mm from the Mukden Arsenal.

Development of the Type 99 and its Modifications

The 6.5mm Type 96 LMG suffered from low stopping power and lacked ammunition compatibility with the Type 92 heavy machine gun, complicating battlefield logistics. Drawing from combat experience in China, the Army Technical Headquarters was tasked with developing a new 7.7mm light machine gun. The primary objectives were absolute reliability, a maximum weight of 11 kg, and compatibility with both rifle and heavy machine gun ammunition.

The first prototypes were completed by June 1938, followed by a second model in November. These trials successfully addressed recoil issues through the study of new cartridges. Notably, the barrel life was significantly increased, reaching an impressive 21,000 to 24,000 rounds when using Type 97 ammunition.

The Type 99 prototype was a Type 96 rechambered for 7.7 mm caliber. The rear monopod and flash hider are absent.

In early 1939, several critical improvements were implemented:

- Ammunition Feed: Adoption of a curved box magazine.

- Reliability: The chamber was redesigned to ensure smooth operation without the need for cartridge lubrication (a major flaw in earlier designs).

- Durability: New extractor types were tested to eliminate ejection failures, and simplified, sturdier bipods were introduced.

- Barrel Exchange: A new locking mechanism was developed to ensure absolute barrel interchangeability.

By May 1939, after proving that its automatic fire accuracy surpassed previous standards, the weapon underwent practical trials at the Army Infantry and Cavalry Schools. Following minor adjustments based on their feedback, the design was finalized and officially adopted as a standard service weapon in July 1939.

Type 99 machine gun.

| Specification |

Type 99 |

| Caliber |

7.7 mm |

| Overall Length |

1.185 m |

| Total Weight |

9.9 kg |

| Muzzle Velocity |

715 m/s |

| Maximum Range |

3500 m |

| Rate of Fire |

550 rpm |

| Feed System |

Box magazine |

| Magazine Capacity |

30 rounds |

| Bullet Weight |

11.8 g |

The optical sight for the Type 99 machine gun was updated with a new reticle specifically calibrated for the 7.7mm cartridge. In 1940, development began on a new machine gun suppressor; although the specific weapon model was not identified in the documentation, the project was scheduled for completion by 1943. Given the timeline, it is highly probable that this 1940 suppressor program was intended for the Type 99 machine gun, which had been adopted just a year prior.

Reticle of the Type 99 optical sight.

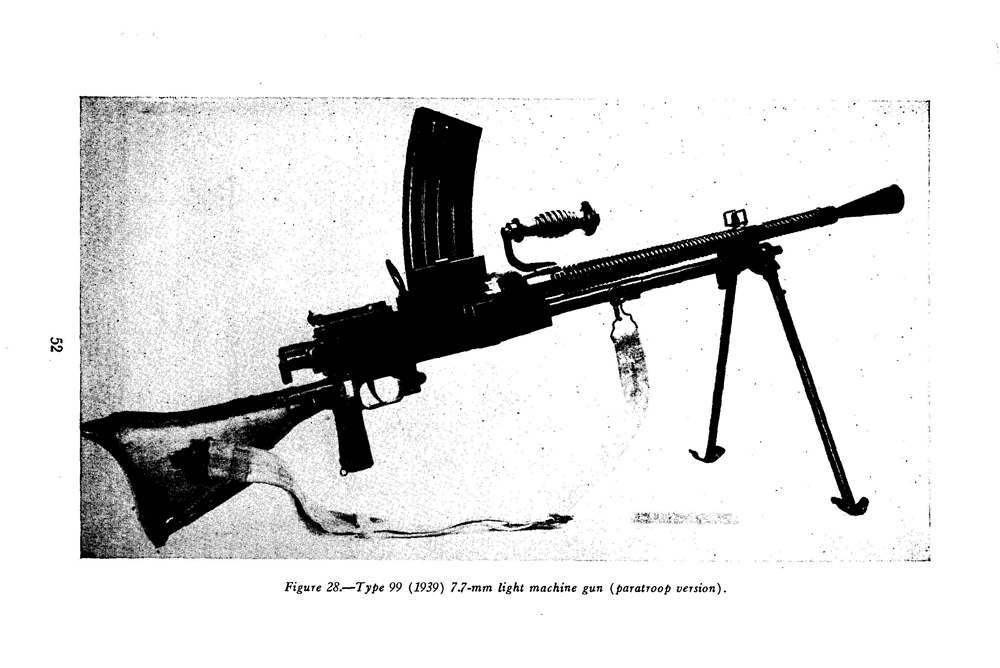

In July 1944, a prototype light machine gun designed for paratrooper units (under the secret code name “Te-Ki”) was completed. Along with a concurrently developed prototype automatic cannon for paratroopers (code-named “Te-Ji”), it underwent acceptance trials at the Irago Proving Ground. However, the weapon was never officially adopted for service.

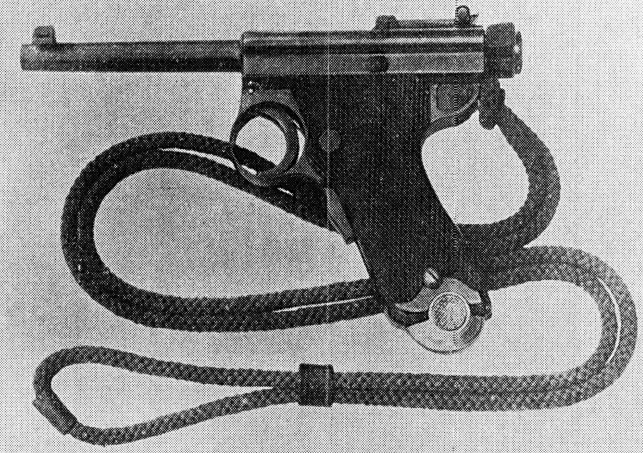

Paratrooper Type 99 machine gun.

| Specification |

Paratrooper Type 99 |

| Caliber |

7.7 mm |

| Total Length |

1.19 m |

| Barrel Length |

0.55 m |

| Weight (Loaded) |

11.43 kg |

| Muzzle Velocity |

714.7 m/s |

| Operation |

Gas operated |

| Rate of Fire (Cyclic) |

540–550 rpm |

| Rate of Fire (Effective) |

120 rpm |

| Sights |

200 to 1,500 m |

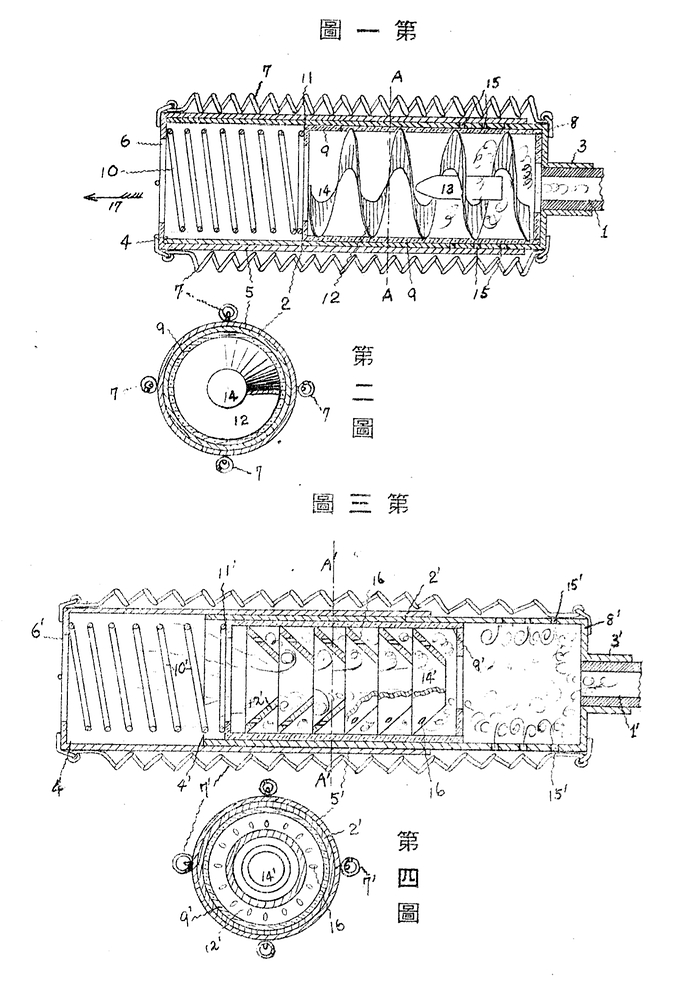

Type 1 and Type 3 Machine Guns

Despite the overall effectiveness of the Type 99, the Japanese military launched a development program for a next-generation light machine gun aimed at addressing the Type 99’s remaining shortcomings. This program resulted in three distinct prototypes submitted by different manufacturers.

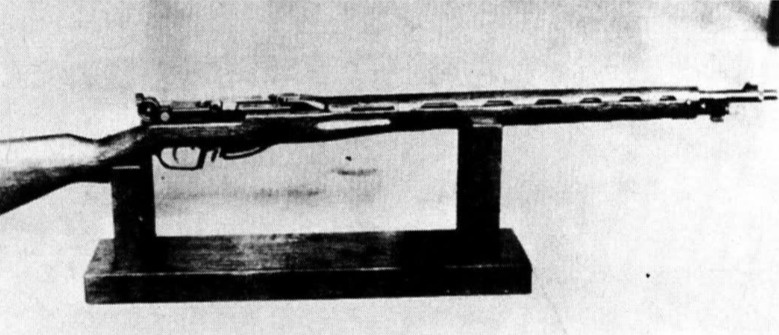

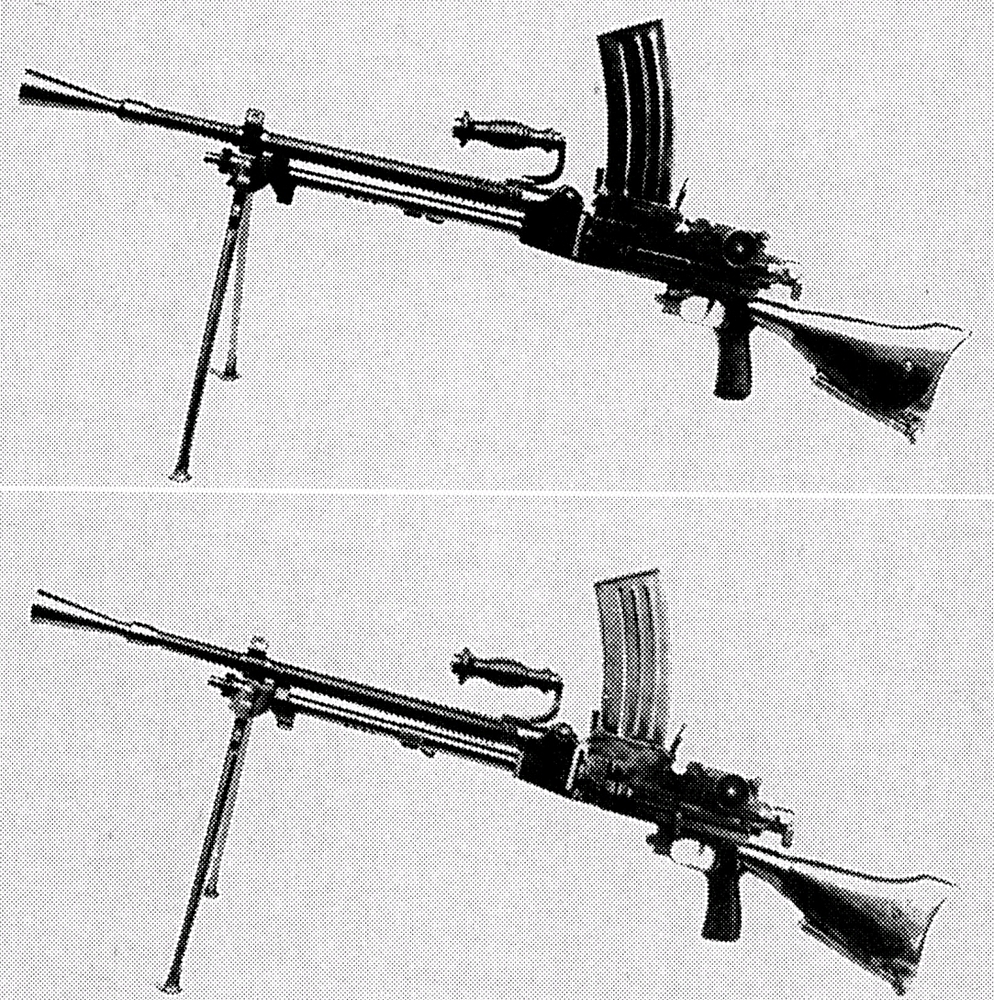

Type 1 Model 1, produced by the Nambu Rifle Manufacturing Company, was an enhanced version of the Type 99 with a increased rate of fire. A key feature of this model was its modular design, allowing for rapid assembly and disassembly — a characteristic specifically intended for paratroopers. It retained the standard top-mounted box magazine used by the Type 99.

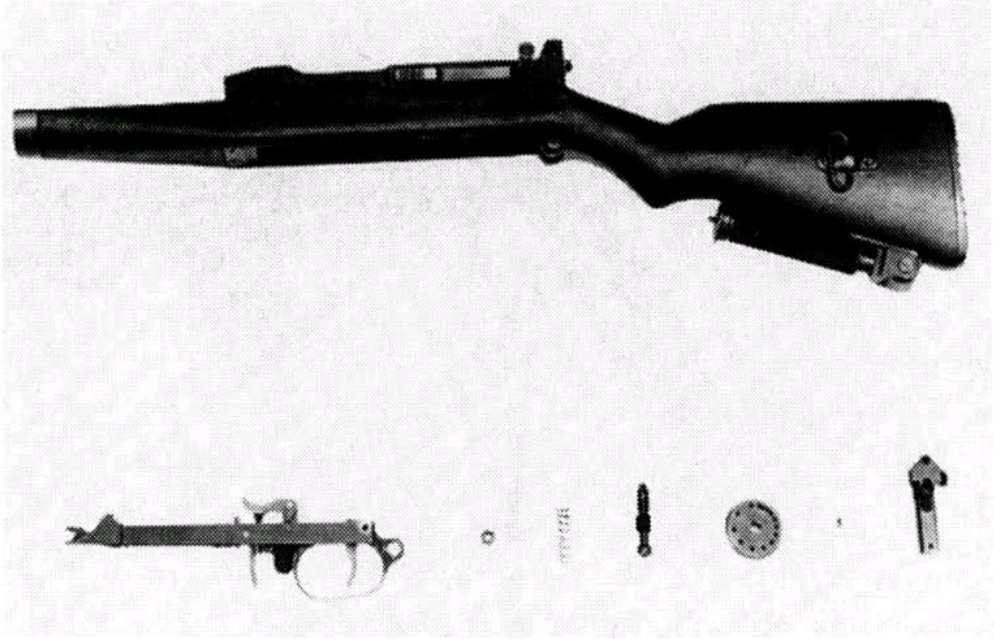

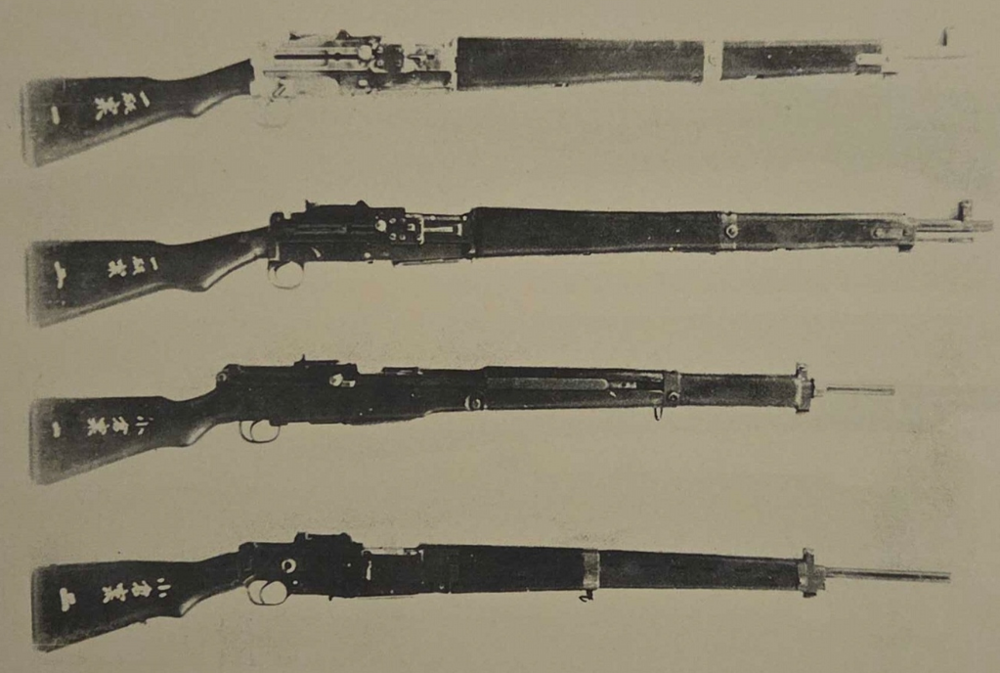

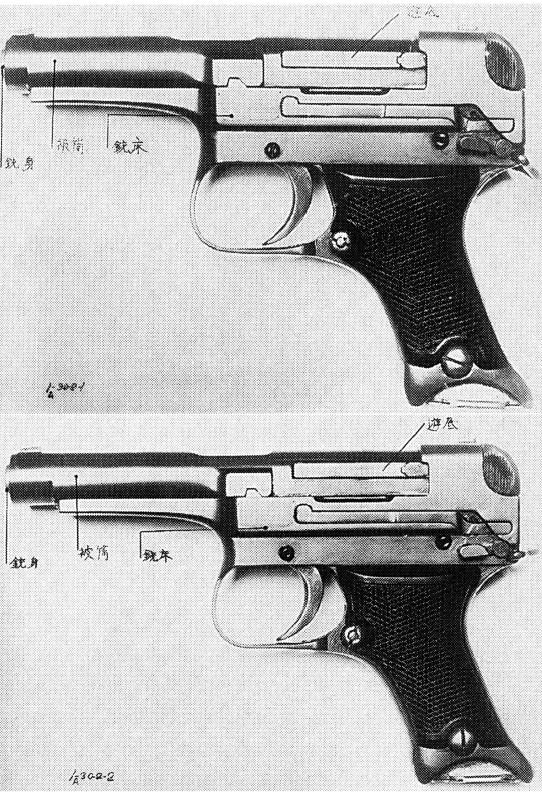

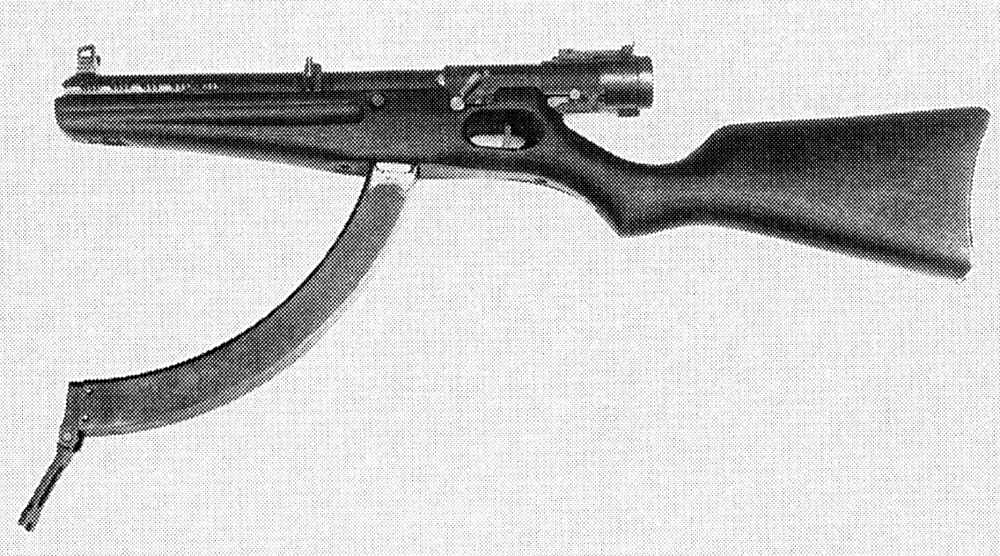

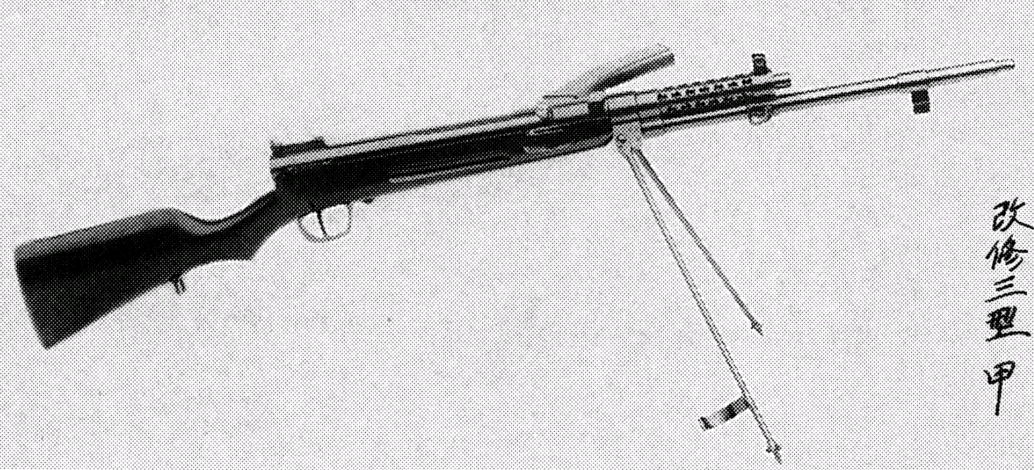

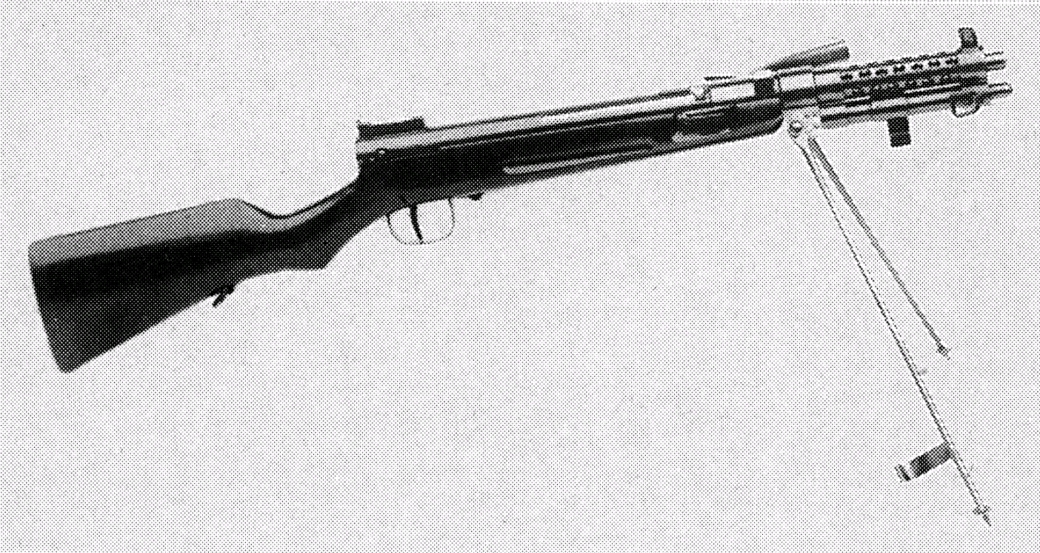

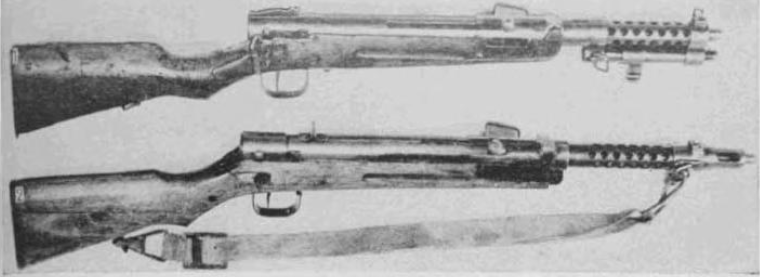

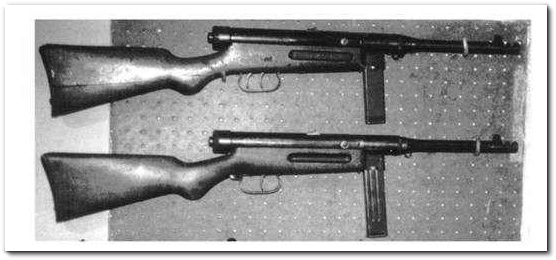

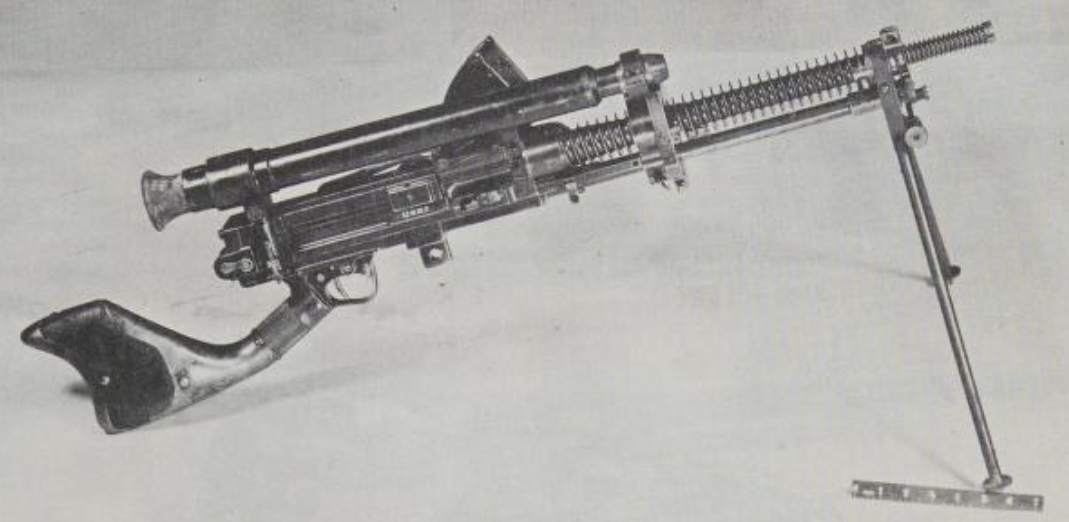

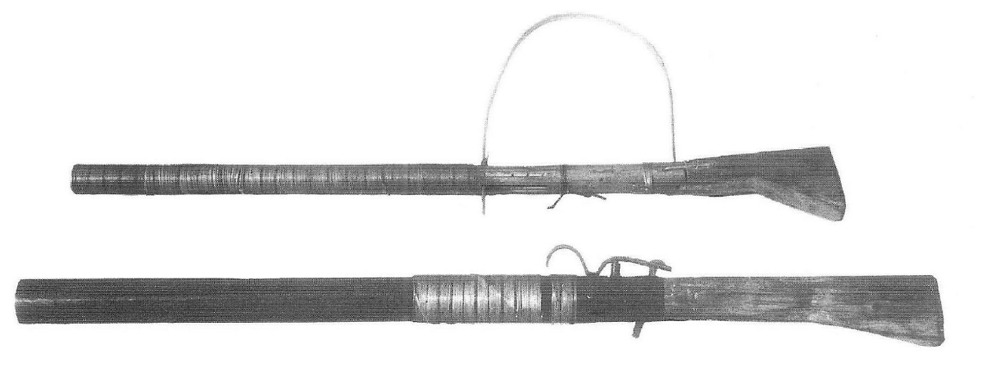

Type 1 Model 1 machine guns from the Nambu factory. The Ko version is on top, and the Otsu version is on the bottom.

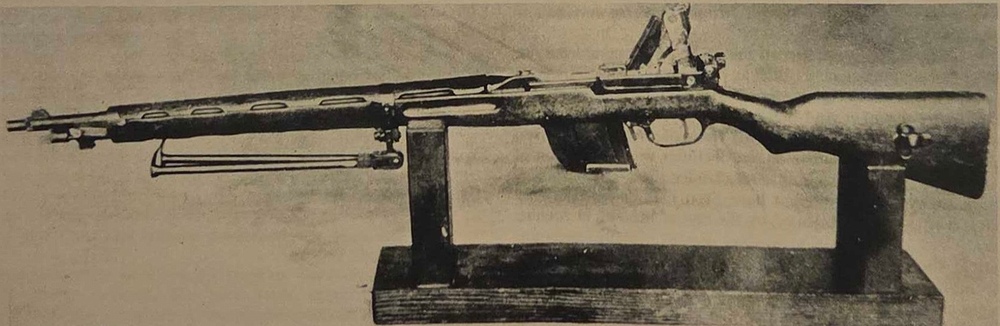

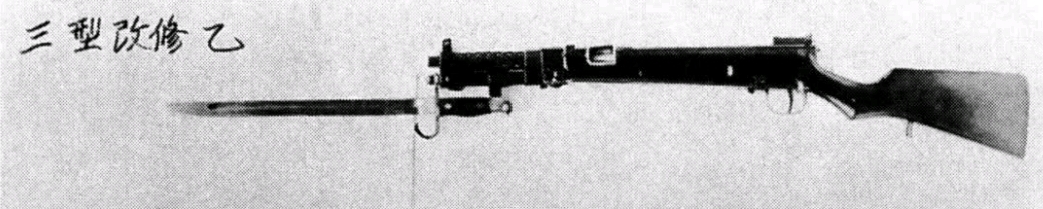

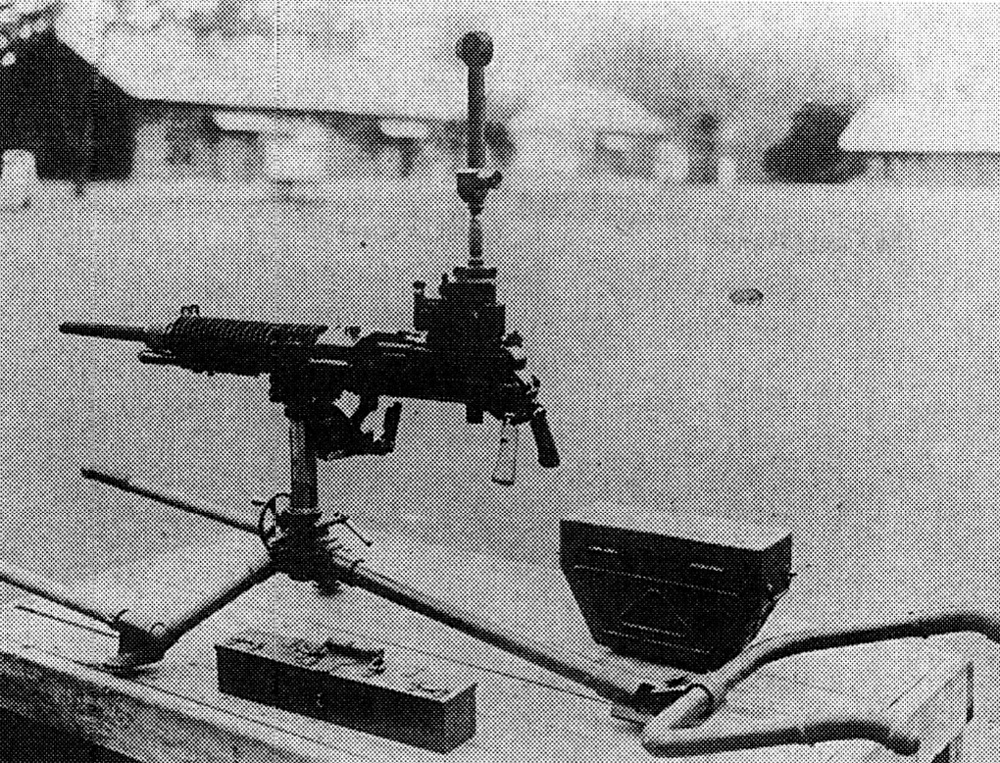

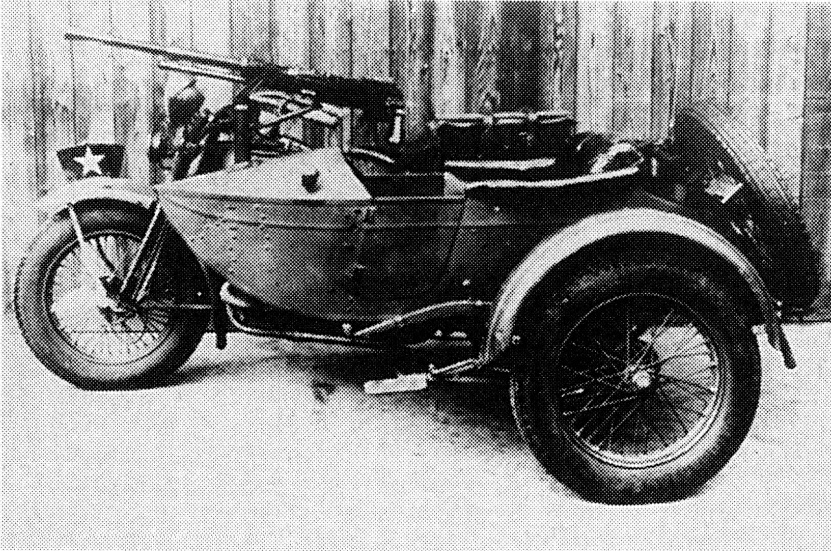

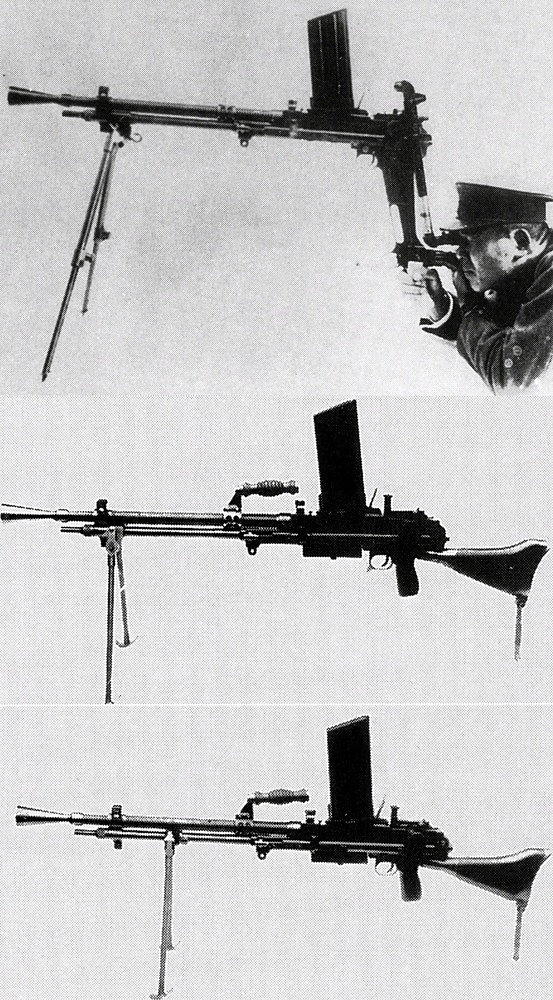

Type 1 Model 2, developed by Tokyo Gas & Electric (TGE), was initially designed for dual-ammunition compatibility with both Type 99 and Type 92 7.7mm cartridges. It utilized a rigid strip-feed system, identical to the Type 92 heavy machine gun. Two variants were produced: Model 2 Ko and Model 2 Ostu, with the latter featuring a rear monopod. Notably, the stock was attached directly to the rear of the receiver rather than the underside, which improved stability and accuracy during automatic fire.

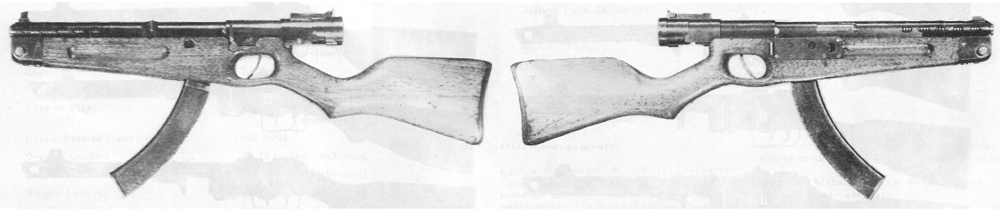

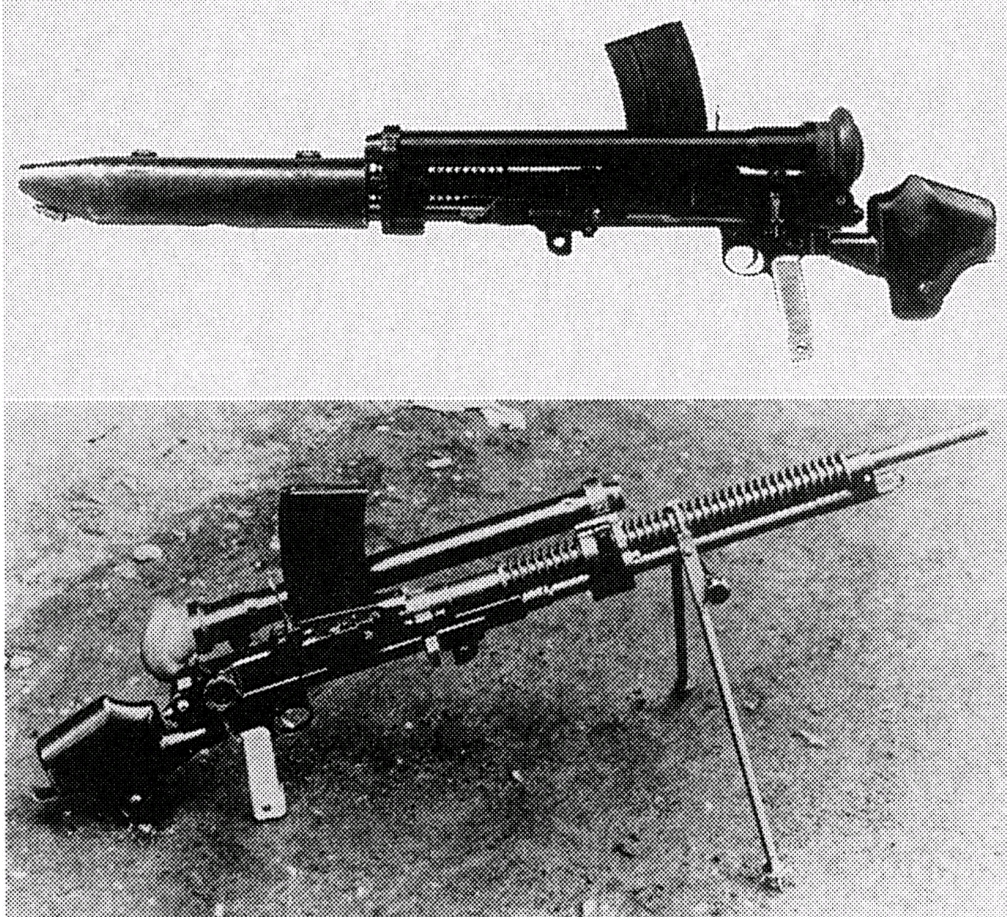

Type 1 Model 2 machine guns from the Tokyo Gas & Electric. The Ko version is on top, and the Otsu version is on the bottom.

More photos

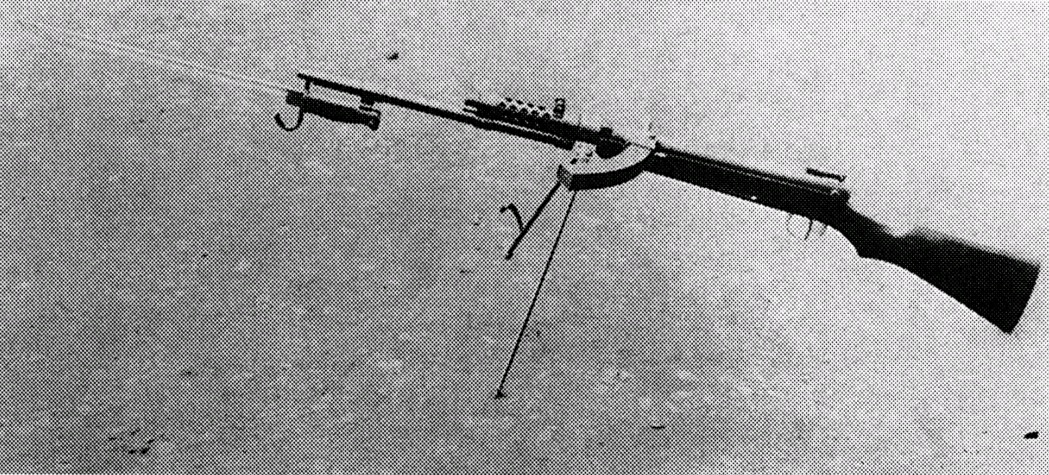

Type 1 Model 2 machine gun on a mount.

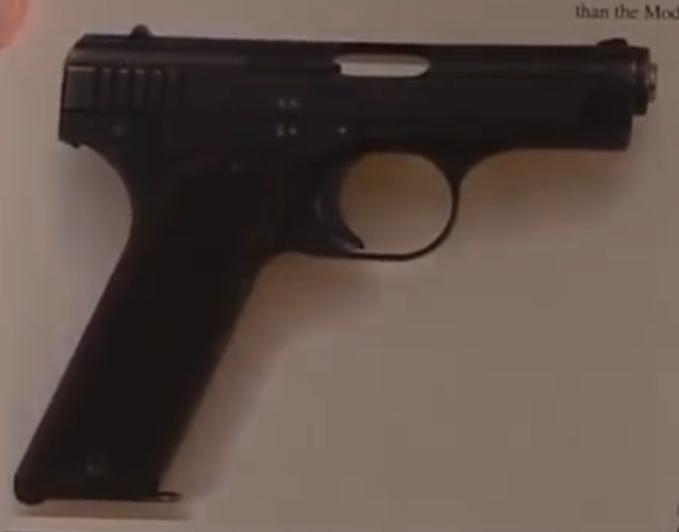

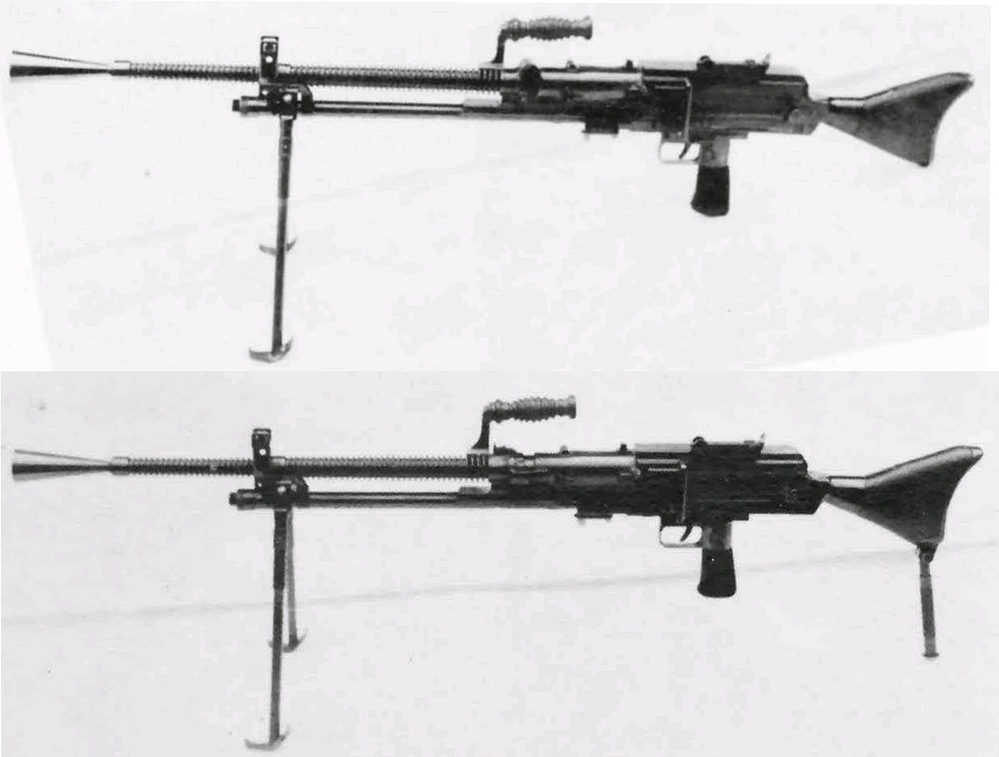

Type 1 Model 3, proposed by the Nagoya Arsenal, focused on ease of mass production. This model utilized a vertical box magazine inspired by the Czechoslovakian ZB-26, as this feed system was deemed simpler and more cost-effective to manufacture than previous Japanese designs.

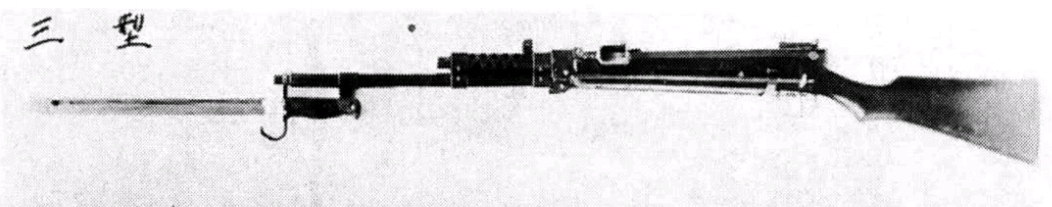

Type 1 Model 3 machine gun. At the top is the version for firing from behind cover; in the middle is the Technical Headquarters variant; at the bottom is the Nagoya Arsenal variant.

The experience gained from these prototypes eventually culminated in a final, unified design, also designated as the Type 3. This final iteration adopted the rigid strip-feed system as its primary method of ammunition delivery. The stock was a slimmed-down version of the Model 1 design, and the rear monopod was relocated from the buttstock to the pistol grip. In its final form, the Type 3 functioned less like a traditional light machine gun and more like an early General-Purpose Machine Gun (GPMG).

Type 3 machine gun.