Good afternoon everyone, today I received the Hino-Komuro rifle from BP and decided to offer the Hino-Komuro pistol for Japan as an event weapon. For a full set so to speak. Here it is, the fruit of dusky Japanese genius (or pervert, as you may say) Hino - Komuro pistol:

Pistol cocked, right side view

HISTORY OF THE GUN:

The mass production for commercial sale of the Hino-Komuro pistol was started at the factory of Tomishiro Komuro (hence the name of the pistol) in 1905. However, the pistol was not a commercial success, and in 1912 the production was curtailed. During the whole period of production from 1905 to 1912, according to different estimates, from 1200 to 500-600 units were produced.

With holster and magazine

The Hino Komuro pistol was developed in 1904 by Japanese army lieutenant Kumaso Hino.Kumaso Hino and Tomishiro Komuro hoped to develop a pistol for the Japanese army and receive a military order, but the weapon was not satisfactory to the military, who considered it insufficiently reliable in terms of safety.

In 1908, Hino tried to enter the American market and received a patent for his invention in the USA. After that the pistol was named Hino-Komuro M1908. Production of the pistols continued until 1912. Due to several accidents during development and testing of the gun, as well as due to the specific design of the gun in Japan, it did not gain wide popularity. In 1912 the production of pistols was discontinued.

Rear view of the bolt and grip.

Features:

Design: the bolt was fixed, and the barrel extended forward, creating an opening in the breech. To cock the gun, the movable barrel had to be pulled forward.

The automatic rifle uses the energy of the bullet, which, when fired, is cut into the rifle’s rifling grooves and pulls the movable barrel forward.

Sights: rounded front sight and rear sight, mounted on the top of the frame.

The magazine capacity was from 7 to 15 rounds, depending on the type of ammunition used.

Calibers: 6.35mm Browning, 7.65mm Browning, 8mm Nambu, and even 5mm ammunition.

Dimensions and weight: 7.65 Browning caliber pistol had magazine capacity of 8 rounds, overall length of 256 mm, barrel length of 202 mm, weight without ammunition was 820 grams.

The magazine is for 7 rounds of .32 ACP.

Principles of operation:

Principles of operation:

And here is where things are really interesting, for they are really unique.

The main part of the Hino-Komuro pistol was a large unit that functioned as a classic frame and bolt carrier (or a full-fledged receiver). This part could be molded as a single unit, machined, and fitted with additional assemblies mounted inside and on the external cutouts. The upper part of the frame functioned as a barrel and bolt casing, and because of its immobility it could be a real receiver. The front part of the frame was cylindrical, and the middle part was octagonal. The rear wall of the receiver had a threaded hole for installing the main parts of the weapon and fixing them in the desired position. Inside the “receiver box” there was a cylindrical channel to accommodate the barrel. The barrel was to be held in position by a hole in the front wall of the casing, and its breech block was to be in contact with the corresponding surface of the inner channel of the casing.Under the rear part of the casing there was a pistol grip with a characteristic swell in the front part of the barrel and bolt. The trigger was located in the front part of the grip.

Magazine on all sides.

The main internal part of the Hino-Komuro pistol was the barrel, which was of a special design. The outer diameter of the barrel was equal in its front and middle parts. The rear part of the barrel was thickened to make contact with the recoil spring and the inner surface of the barrel casing. In addition, there was a small groove on the underside for contact with the trigger. On the sides of the muzzle there was a notch, which was proposed to be used for cocking the weapon. At the top of the rear section of the chamber, there was a small cutout for the cartridge case extractor.

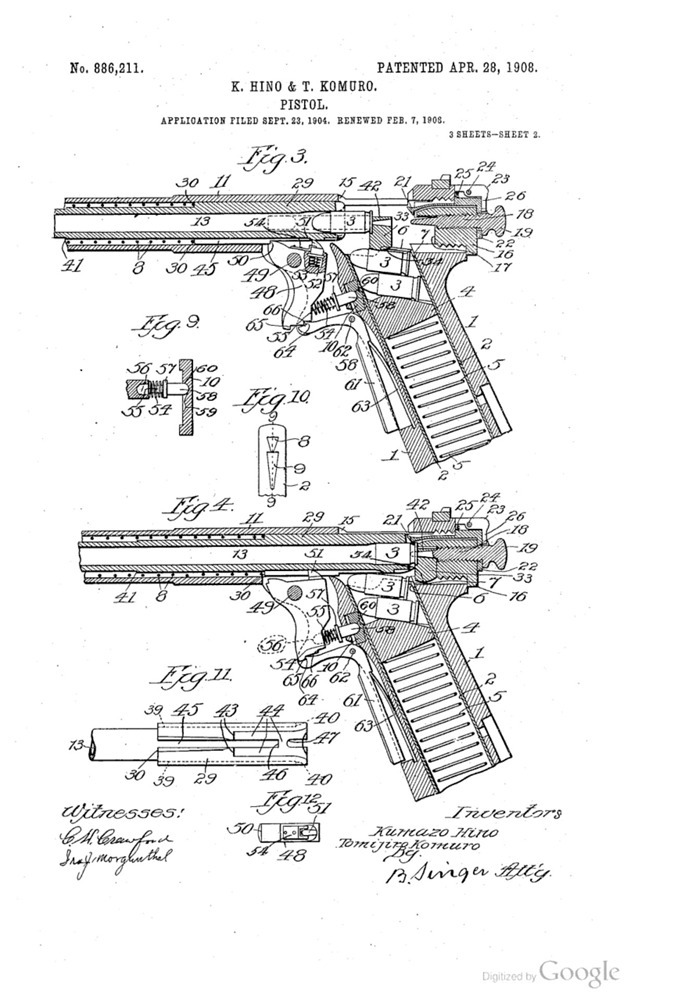

Hino-Komuro Pistol Patent

When assembled, the barrel was fitted with a cylindrical recoil spring, and then placed inside the “receiver”. The muzzle of the barrel passed through the breech block, the thickened breech block came into contact with the middle part of the breech block, and the spring was sandwiched between the front wall of the breech block and the breech block. A curious feature of the Hino design was the use of a relatively weak recoil spring. Because of this, the gun could be cocked with two fingers.

Another scheme of the Hino-Komuro pistol.

In the rear opening of the casing, the bolt was threaded through the bolt block, which acted as a breech block. It was responsible for firing and extracting the fired cartridge case. It was based on a cylindrical metal plug with a through hole in the center and a groove at the top. For ease of insertion and removal, the plug had a notched outer edge. On the front (inner) end of the plug there was a rectangular recess, which was to accommodate a special cartridge feeder. It was a rectangular part with a through hole in the upper part. It could be moved back and forth to ensure proper operation of the ammunition system.

The striker was threaded into the center through hole of the bolt plug. This part was made in the form of a screw with a large head and a washer under it. On the other end of the part (inside the gun) was a fixed striker in the form of a thin needle of the required length. In the upper groove of the plug was placed an assembly in the form of an L-shaped base with a spring-loaded lever. The lever was designed to catch the cartridge case and pull it out of the barrel when the gun was fired.

Another scheme of the Hino-Komuro pistol.

The trigger mechanism was of very simple design, but was equipped with an automatic safety. The trigger was a vertically oscillating trigger, which was in the form of a shaped plate with holes in it. It was supported by a small spring at the bottom, and the teeth on the upper edge had to engage with the groove on the lower surface of the barrel. Other parts responsible for the trigger were simply absent. The functions of trigger and whisper were assigned to a single part of the appropriate shape.

In spite of its simplicity, the trigger mechanism was equipped with a full-fledged automatic safety. On the front edge of the grip, under the fingers of the shooter, there was an oblong key. It was an L-shaped lever, the upper part of which interacted with the bottom of the trigger. When the key was pressed, the lever swung on its axis and released the trigger, allowing a shot to be fired. If the gun was not held with the correct grip, the lever would return to its place and prevent the trigger from moving.

To prepare to fire a Hino-Komuro pistol, a magazine had to be placed in the grip of the gun and then the mechanisms were cocked. An unusual feature of Hino’s design was the absence of non-automatic safety and trigger guard.

Disassembled parts.

The gun was cocked by pulling the muzzle forward until it clicked into place. This caused the recoil spring to compress, and the lower groove of the barrel to engage the upper prong of the trigger. In addition, as the barrel moved forward, the bolt was moved from its place in the front part of the bolt, and the feeder, which was mechanically connected to other parts, was moved forward. It moved forward, pushing the upper cartridge from the magazine to the ejection line, and preventing it from being ejected through the ejection port.

The Hino-Komuro pistol was designed to fire from an open bolt, correcting for the original design with a stationary bolt and movable barrel. When the trigger was pulled, the barrel, which was in contact with the compressed recoil spring, was supposed to move backward. At the same time, the bolt was to move backward, and at the same time the bolt was to be placed in the corresponding cutout in the bolt. At the same time, the firing pin needle passed through the hole in the bolt. As the barrel moved backward, it caught the bullet of the fed cartridge in the chamber and continued its movement. When the barrel reached the rear position, it was finally put on the cartridge, after which the primer of the cartridge struck the firing pin and the shot was fired.

Immediately after firing, due to the absence of moving bolt, the barrel started to move under the action of powder gases. The bullet, knocked out of the cartridge case, traveled along the rifling rifling grooves of the barrel, hitting them and transferring part of its energy to the barrel. This energy was enough to move the barrel to the forward position, where it was locked by the trigger tooth. As the barrel moved forward, the spring-loaded extractor held the empty cartridge case by its edge. The extractor then moved forward again, pushing the fired cartridge case out through the casing window. After ejecting the cartridge case and locking the barrel in the forward position, the gun was ready to fire again.

Disassembled parts IRL.

PREFERENCES OF SUCH AUTOMATIC SYSTEM

- The movable barrel, which starts its movement before the shot is fired, allowed to reduce the recoil of the gun to a certain extent. By moving backward a fraction of a second before the shot, the barrel had to create an impulse pushing the weapon forward and with its help partially canceling the impulse from powder gases and bullet directed in the opposite direction. In this way the impulses were partially offset and reduced the overall effect on the gun.

- The second advantage was the comparative simplicity of the design in terms of adaptation to new ammunition. The automatic pistol, which was based on the barrel roll-out system, did not impose any special requirements to the cartridge, which allowed K. Hino to develop and commercialize several modifications of his pistol for different ammunition. According to various sources, at least three such modifications were produced.

- It is also possible to note the relatively high safety of the gun when used correctly, but only when used correctly. Spontaneous firing without prior cocking and transfer of the barrel to the forward position was impossible, and accidental firing of the cocked gun with the barrel locked in the forward position was to be prevented by the automatic safety.

MINUSES OF SUCH AUTOMATIC SYSTEM

- If the barrel was not locked in the forward position when cocking the weapon, the reverse movement of the barrel under the action of the spring could lead to a shot with unpredictable consequences.

- Another problem was cocking mechanisms by shifting the barrel. This procedure was simple, but after firing one or two magazines the barrel became hot and did not allow the shooter to work with bare hands. There were no regular means of solving this problem. It was suggested to monitor the cartridge consumption and after the last cartridge was used, to change the magazine without pulling the trigger. In this case, the automatic system was used like a bolt latch, allowing to continue firing without manual reloading of the gun.

Owning this pistol is as dangerous

As living at the foot of Fuji.

The spirit of the samurai is great.

“UPGRADE”

This video is about how a Hino-Komuro pistol works using a 3D replica as an example