Neither shaky nor rolling… Soviet submachine guns. Part 9

The history of the creation of domestic submachine guns. Part 9

In May 1938, the NIIPSVO received submachine guns of the Degtyarev system for NoNo 5 and 6, manufactured by INZ No 2 in 1936.

It should be noted right away that the production of submachine guns (SMG) with modifications lagged behind the GAU instructions for at least a year, and the tests of these PPs did not fall under the requirements of the Decree of the GAU Artillery Committee of 03/11/1938. The fact is that the theory and calculation of automatic mechanisms at that time were in their infancy, and the empirical approach to improving the design was long and difficult.

In this modernization of the SMG, the design was changed and new parts were introduced:

a) the following were changed: bolt, bracket, casing, front sight and sight bar slot profile;

b) the following were introduced: a safety bar for the sight, a magazine guide box for its stable positioning, a guide sleeve for the propeller, a tide with a socket for the propeller, a third fastening screw for the stock.

To facilitate the operation of the trigger parts and moving parts, a bevel of the rear part of the bolt was introduced. The place of cocking the bolt is shifted closer to the breech of the barrel by lengthening the groove on the bolt in order to reduce double shots during single firing and reduce delays in firing.

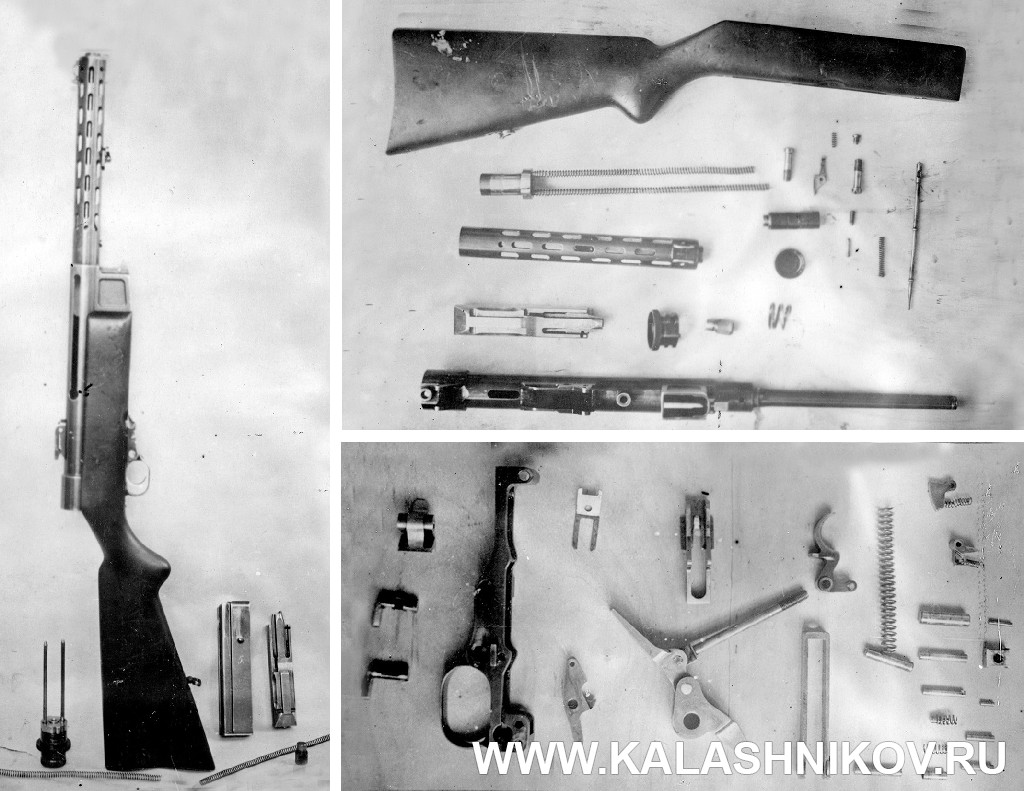

General view (right) of PPD No 1 manufactured in 1937 with a bayonet

As a result of the tests, NIPSVO made the following conclusion:

"Experimental PPDs have, in comparison with the p.p. of gross production, a number of positive aspects, namely:

1. Protection of the sighting bar from accidental blows by the rib safety.

2. A significant reduction in delays in firing by introducing an additional part - the magazine guide box in conjunction with the rearrangement of the firing pin cocking place (closer to the breech face of the barrel).

3. Facilitation of the operation of the mechanisms, due to the presence of a bevel of the rear part of the bolt. These changes can be recommended for their introduction into the p.p. of gross production not in full, since the most significant design change (rearrangement of the bolt cocking point) is structurally not finalized, namely:

a) double shots are not eliminated during single fire;

b) the delays inherent in the gross p.p. are not eliminated - cartridge jamming, non-reflection and pinching of cartridge cases.

Points “a” and “b”, as the most relevant, require further elaboration.

It is possible to recommend the safety of the sight bar, the magazine guide box and the bevel on the rear of the bolt for introduction into the bulk production p.p."

Incomplete dismantling of PPD No 1 manufactured in 1937.

In June 1938, the tests at the NIPSVO received the Degtyarev PP for NoNo 1 and 2 manufactured in 1937.

b) must have the bolt stop after all the cartridges in the magazine have been used up;

c) the rate of fire should be 300-400 rounds per minute;

d) must have a guide for the store.

Due to the fact that PPD No 1 most fully met the requirements of TTT-36, it was taken for testing as the main one. PPD NoNo 1 and 2 manufactured by INZ No 2 in 1937, in comparison with PPD NoNo 2 and 4 tested in 1936 (see No 7 KALASHNIKOV) had the following differences:

PPD No 2 (1937)

- The magazine latch in the stowed position has been changed, it has been moved to the casing at the front swivel. The latch consists of a latch box riveted to the casing, a spring, a stud and the latch itself. In the stowed position, the magazine is held by a latch by the edge at the bottom.

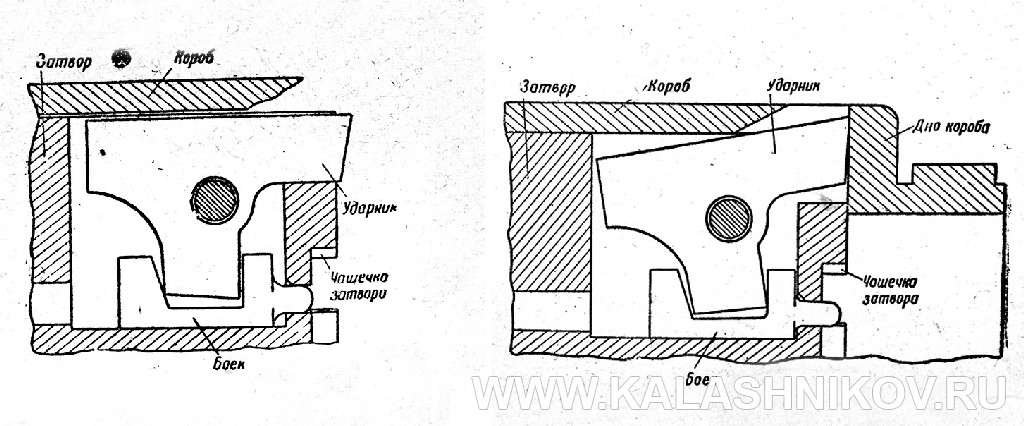

- The guide feet of the firing pin have been changed. The legs are milled on the firing pin at the front and rear ends. To reduce the friction of the firing pin, the legs are cut off. Between the legs there is a comb with a recess for the head of the trigger mechanism.

- The protrusion of the automatic trigger lever resting on the bolt is moved forward to the barrel stump, so that if the firing pin in PPD NoNo 2 and 4 of 1936 was torn off the self-timer at a distance of 4-6 mm from the barrel stump, then in PPD NoNo 1 and 2 of 1937 this distance is 2.5 mm.

- The casing is made hexagonal. The edges of the casing are hardened. A bladed bayonet is attached to the end of the casing.

- The sight has a movable rear sight with a lead screw. The front sight is rectangular, the rear sight slot is semicircular.

- The lid cup (butt plate) is connected to the receiver and cover by means of a cracker connection.

- The guide rod of the firing pin spring is made of tube and has a coil spring rod inside. The rod head serves as a latch for the receiver cover cup.

- The bolt handle has a latch to hold the bolt in the rear position while eliminating the delay in firing.

In PPD No 1 (1937), in addition to those listed:

- The magazine mounting clip was changed. In the front part, the clip has a pin for the convenience of holding the SMG during firing.

- There is a mechanism that holds the bolt in the rear position after all the cartridges in the magazine are used up. The mechanism consists of three levers, a stud and a spring.

- Changed the magazine. The magazine feeder has a protrusion that presses the lever and stops the bolt in the rear position. After using up the cartridges in the magazine, the magazine feeder comes to the upper position and presses the lever that stops the bolt in the rear position. The lever, turning on its axis, sinks the tooth into the receiver and delays the bolt.

As a result of the tests, the following points were emphasized: “The longer time spent on assembly and disassembly is explained by the complexity of the trigger mechanism and the difficulty of catching the thread entry of the butt plate with the receiver. The rear sight on the sight allows you to make corrections: to the wind, derivation and when zeroing. The finger on the magazine clip prevents the magazine from being skewed by the shooter’s hand when firing, provides more convenient removal of the magazine from the clip and allows you to hold the magazine with your left hand when shooting. The magazine latch does not allow you to move the magazine from the traveling position to the firing position without the help of foreign objects. The mechanism for holding the bolt in the rear position works reliably and creates convenience when shooting. Changing the guide feet of the firing pin ensures better direction of the firing pin into the slot of the receiver.”

In general, the following conclusions were made: "The PPD NoNo 1 and 2 proposed for testing, manufactured by INZ No 2 in 1937, are an improvement of PPD NoNo 2 and 4 izg. 1936

1. PPD No 1 is the most modified sample and has passed tests on the following points:

a) durability of parts and low (1.4) % delays;

b) the accuracy of the fire is equivalent to the accuracy of the gross RPD;

c) has a number of improvements (improved magazine clip, movable rear sight, bolt stop, etc.).

2. PPD No 1 did not pass the test on the following points:

a) allows firing a shot with the bolt not opened;

b) the rate of fire is high (592 rds/min), and for the TTT-36 300-400 rds/min;

c) the possibility of firing is not eliminated when the delay is eliminated due to the fact that the firing pin may get stuck in the middle of the path between the cocking and the bolt firing pin due to contamination, and when the bolt is quickly pulled back by hand, it will hit the firing pin and break the cartridge primer;

d) in case of clogging with sand, the trigger mechanism fails;

e) the changes made to the design are not finalized: the receiver cover cup, the latch for transferring the magazine to the stowed position.

3) The strength of the blade bayonet and casing (due to the attachment of the bayonet to it) is satisfactory. Attaching the bayonet to the shaft PPD will necessitate structural changes to the casing."

The result of these tests was the Conclusion:

"On the basis of the above, the Scientific Test Site of Small Arms of the Red Army believes that:

1. The PPD NoNo 1 and 2 submitted for testing, manufactured at INZ No 2 in 1937, did not pass the tests and in their present form cannot be recommended for military trials, since they are unsafe when firing.

2. In the manufacture of shaft PPDs, the following improvements are recommended:

a) movable rear sight of the sight frame;

b) a magazine guide clip with a pin for holding."

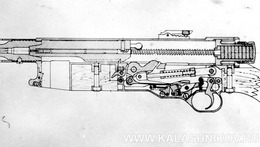

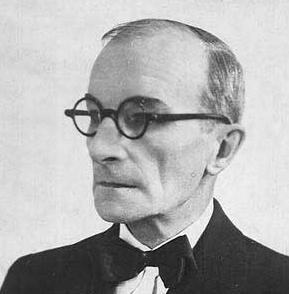

In September 1938, a submachine gun designed by Korovin was completely modified compared to the samples previously tested in 1929-1932. The PPK automation was based on the principle of removing powder gases through four radially located holes in the barrel at an angle of 90 degrees. Gases flowing from the barrel bore affected the rod put on the barrel. The barrel bore was locked by tilting the bolt downwards. The trigger mechanism allowed single and continuous fire. A two-row box magazine for 25 rounds was held by a latch in front of the magazine. All large parts were made in the form of bodies of rotation and could be made on lathes. Disassembly and assembly of the PPK was carried out without the use of tools.

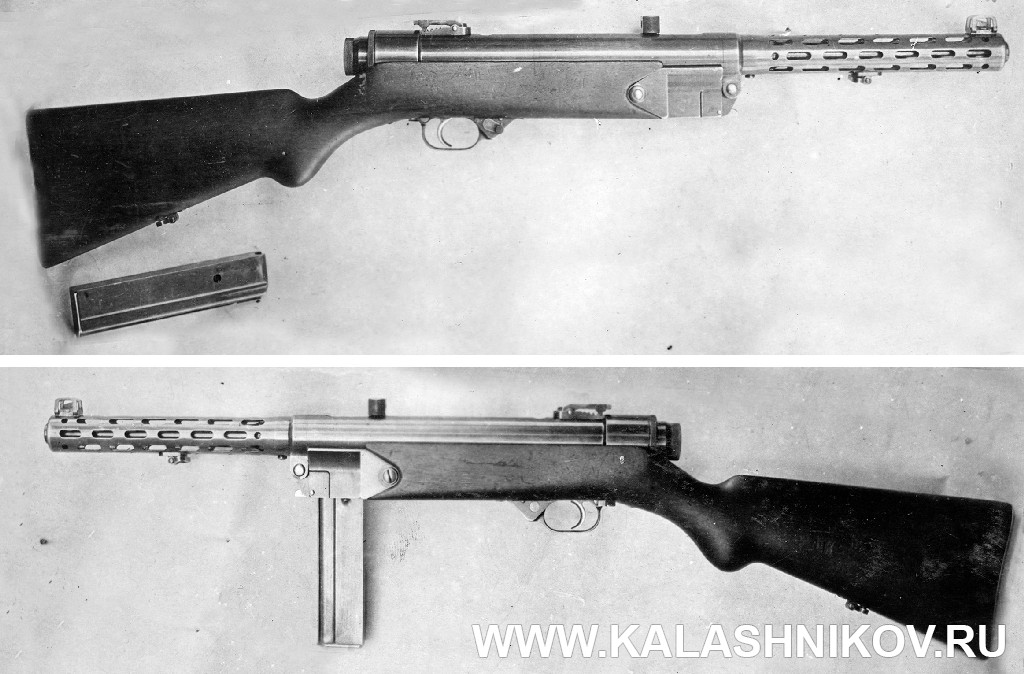

General view of Korovin’s PPK (right, top)

In general, the PPK showed good results in tests, which, however, were no better than those of the PPD. As evidenced by the conclusions of the landfill:

«1. In production and economic terms, SPC will be somewhat more complex in comparison with PPD. The most complex parts of the PPK in terms of the degree of processing are the stem, bolt and casing.

2. In terms of accuracy and accuracy, PPK is equivalent to PPD.

3. With the introduction of the tray in the PPK, the muzzle toss when firing is not completely eliminated. As a result of the toss when shooting from the hand at a distance of 100 m, the average point of impact increases by 35 cm compared to shooting from a stop (in the PPD - by 50 cm).

4. According to the weight data, the PPK is heavier than the PPD by 400 g.

5. In terms of reliability of automation, PPK is equivalent to PPD.

6. The ACC is sensitive to contamination and thick grease, while due to the large rubbing surface of the moving parts, it does not work at all.

7. The PPK is unsafe when firing, when delays are eliminated and cartridge cases rupture.

8. In the assembly, the PPK causes inconvenience when aligning the bolt window with the rod window when inserting the reloading handle.

9. Due to the lack of shock absorption of the firing pin at the time of firing, the PPK gives penetration of the primers (with the breakthrough of gases through the latter)."

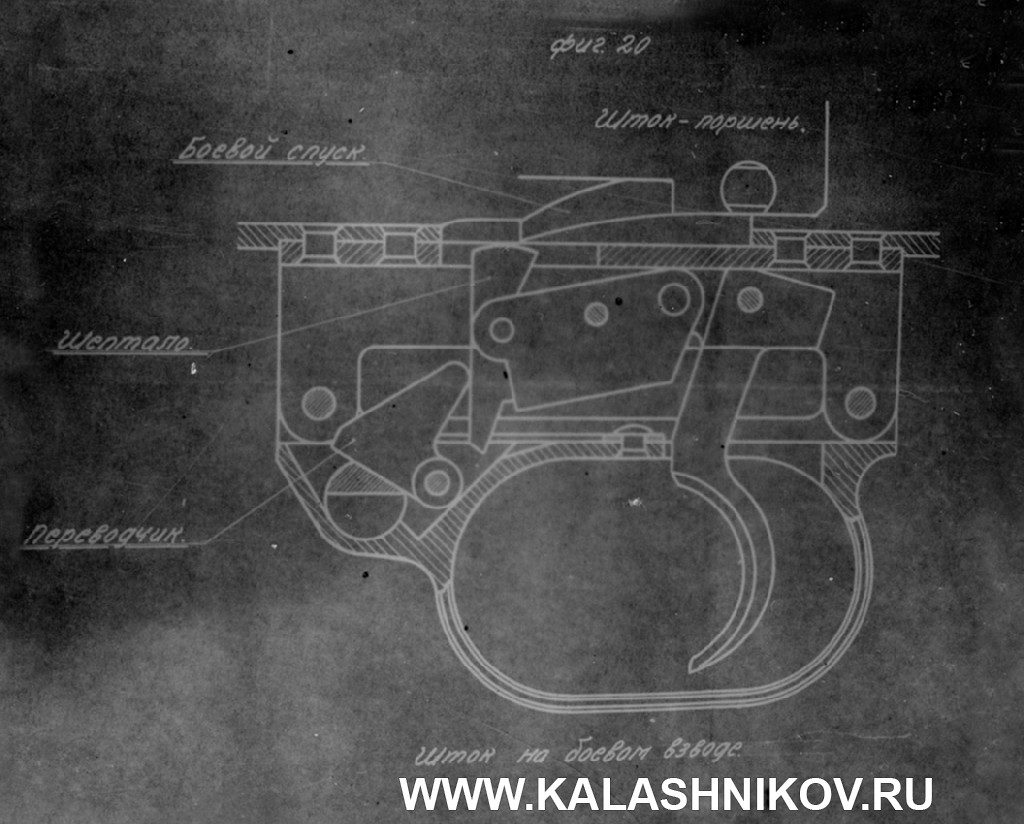

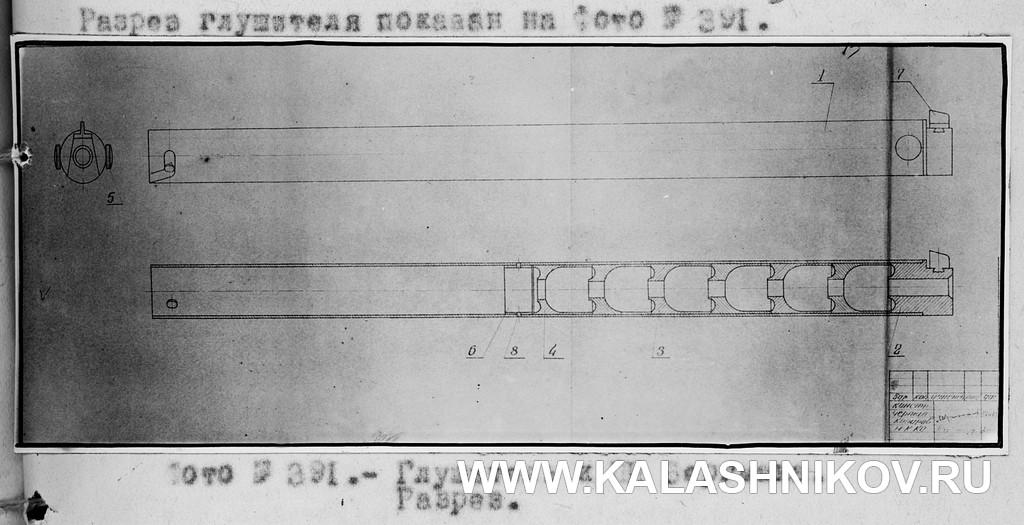

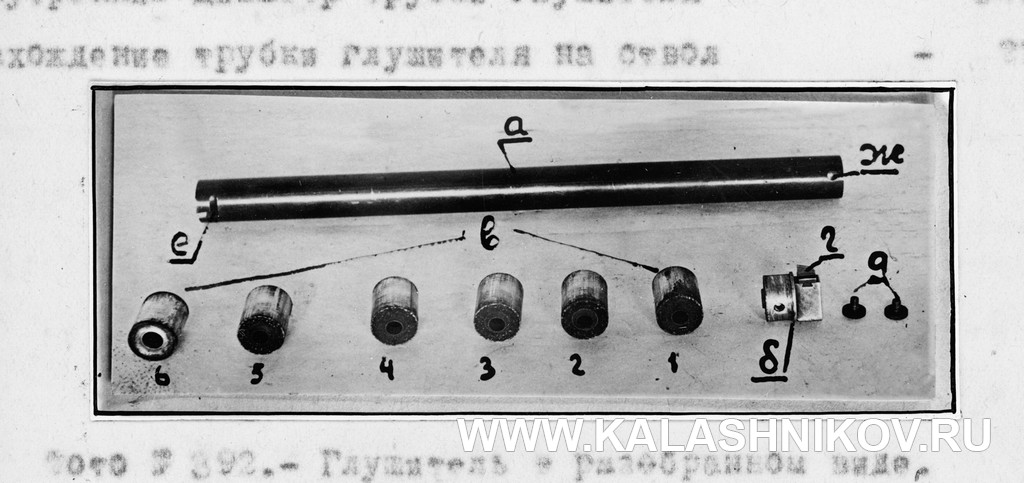

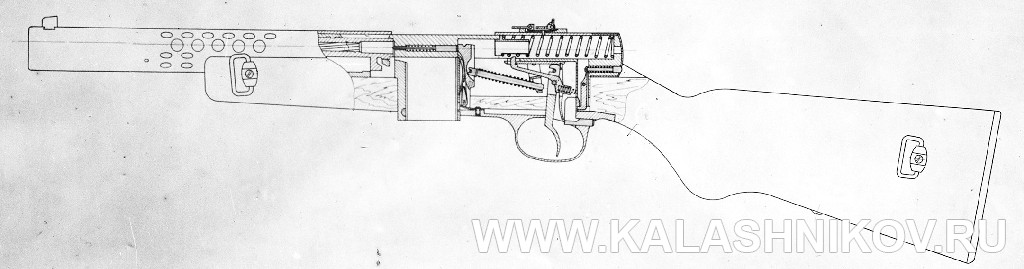

Drawing (section) of the PPK

In connection with the above, the conclusion of the test site is not surprising:

“Based on the test results obtained, the Research Range of Small Arms of the Red Army believes that: the Korovin submachine gun has no significant advantages in terms of design, reliability of automation, accuracy and accuracy of fire, compared to the PPD. It requires taking precautions and more frequent cleaning when eliminating delays, and therefore the PPK is not recommended for armament by the Red Army, because it cannot be finalized without major design changes.”

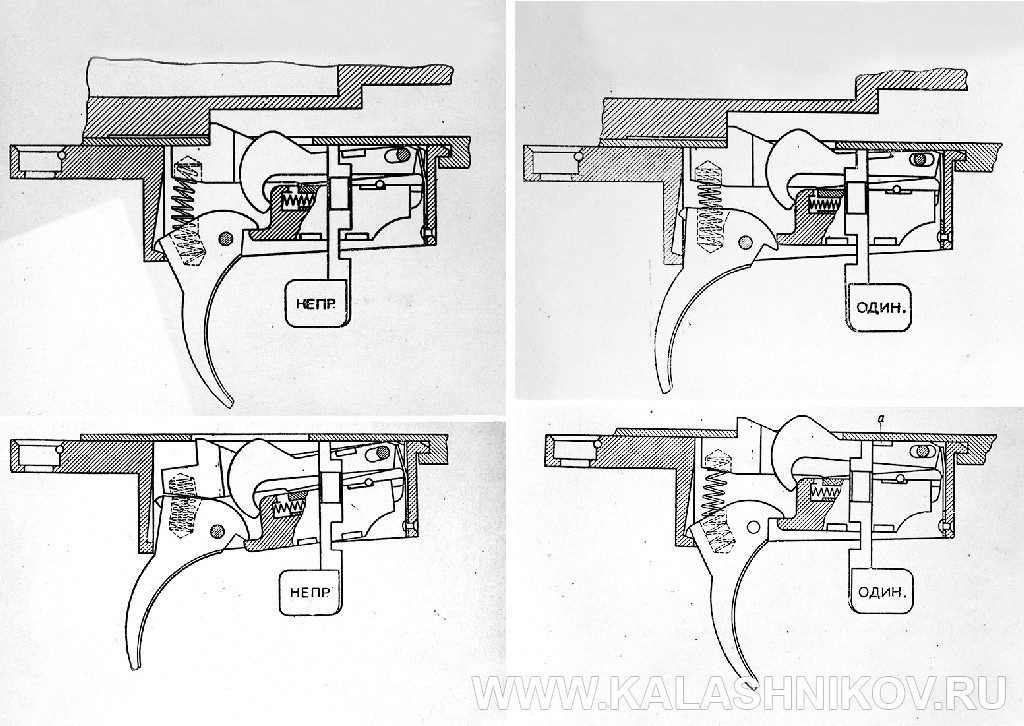

Scheme of the PPK trigger mechanism

On the whole, 1938 passed neither shaky nor rolling, calm and measured. No one rushed either manufacturers or testers. With the loss of the main high-ranking champion of this type of weapon, the situation was very reminiscent of the Russian road - “you can’t accelerate quickly, but you can’t jump out of the rut either.” But for competitors - champions of the self-loading rifle, 1938 was a milestone year - the 7.62-mm Tokarev SVT-38 self-loading rifle was adopted for service. Of course, after all, the curator of the SVT was Comrade Stalin himself! Very little time will pass and the far-fetched competition of these types of weapons will “sink into oblivion”. But this will “need” a small, bloody war.

Of course, RPM and PPS were in service, the last of which many historians and gunsmiths are generally considered to be the best submachine gun of that war. But practically no one knows that there was also a Korovin submachine gun, in many respects in no way inferior to its “older brothers”.

Of course, RPM and PPS were in service, the last of which many historians and gunsmiths are generally considered to be the best submachine gun of that war. But practically no one knows that there was also a Korovin submachine gun, in many respects in no way inferior to its “older brothers”. Yes, in extreme cases it could be manufactured (the Tula Arms Factory, after all!), But it took too much time. Such luxury no one was going to provide to the defenders.

Yes, in extreme cases it could be manufactured (the Tula Arms Factory, after all!), But it took too much time. Such luxury no one was going to provide to the defenders. Therefore, the inventor had to be satisfied only with the development of prototypes on an initiative basis. Weapons, which then dusted in the windows of the Tula gun shop. It was there that the authorities found a submachine gun, which Sergei Alexandrovich once created to participate in the competition, where he won the PAP.

Therefore, the inventor had to be satisfied only with the development of prototypes on an initiative basis. Weapons, which then dusted in the windows of the Tula gun shop. It was there that the authorities found a submachine gun, which Sergei Alexandrovich once created to participate in the competition, where he won the PAP. Simplicity is the key to the success of this product of Sergei Alexandrovich. The Korovin submachine gun, which managed to fight at Tula, was radically different from the weapon that was submitted to the contest. So, he completely lacked a wooden bed, which required a long and painstakingly cut, and also there was no barrel casing. The latter required a special punching, which in those circumstances simply did not have time.

Simplicity is the key to the success of this product of Sergei Alexandrovich. The Korovin submachine gun, which managed to fight at Tula, was radically different from the weapon that was submitted to the contest. So, he completely lacked a wooden bed, which required a long and painstakingly cut, and also there was no barrel casing. The latter required a special punching, which in those circumstances simply did not have time. The trigger and trigger mechanism of the weapon allowed the shooter to lead only automatic fire. “Zest” was a whisper, considerably advanced. This position of his provided high accuracy of the first shot. Trigger hook had a relatively long and smooth stroke, the force on it did not exceed 2.9 kg. A special ejector was responsible for the extraction of the fired cartridge case and for its removal from the weapon. It was fixed to the bottom of the receiver.

The trigger and trigger mechanism of the weapon allowed the shooter to lead only automatic fire. “Zest” was a whisper, considerably advanced. This position of his provided high accuracy of the first shot. Trigger hook had a relatively long and smooth stroke, the force on it did not exceed 2.9 kg. A special ejector was responsible for the extraction of the fired cartridge case and for its removal from the weapon. It was fixed to the bottom of the receiver. On the folding wire butt, the backplate was attached (it could turn). A wooden cheek was put on the pistol grip of the weapon. Since these weapons in the “military” version did not have forearm, the fighter held his hand for a store made by the method of cold stamping. Capacity - 35 rounds, the chess location of the ammunition. Like other Soviet weapons of this class, this Russian submachine gun was used by the standard Soviet patron of that time - 7.62x25.

On the folding wire butt, the backplate was attached (it could turn). A wooden cheek was put on the pistol grip of the weapon. Since these weapons in the “military” version did not have forearm, the fighter held his hand for a store made by the method of cold stamping. Capacity - 35 rounds, the chess location of the ammunition. Like other Soviet weapons of this class, this Russian submachine gun was used by the standard Soviet patron of that time - 7.62x25.