At Tier 3, Germany is inferior to other parties in the Small Arms category, which is especially noticeable in the Self-Loading Rifles and Submachine Guns categories. Therefore, I propose introducing the Suomi M31 at Tier 3 (to the leveling branch for experience).

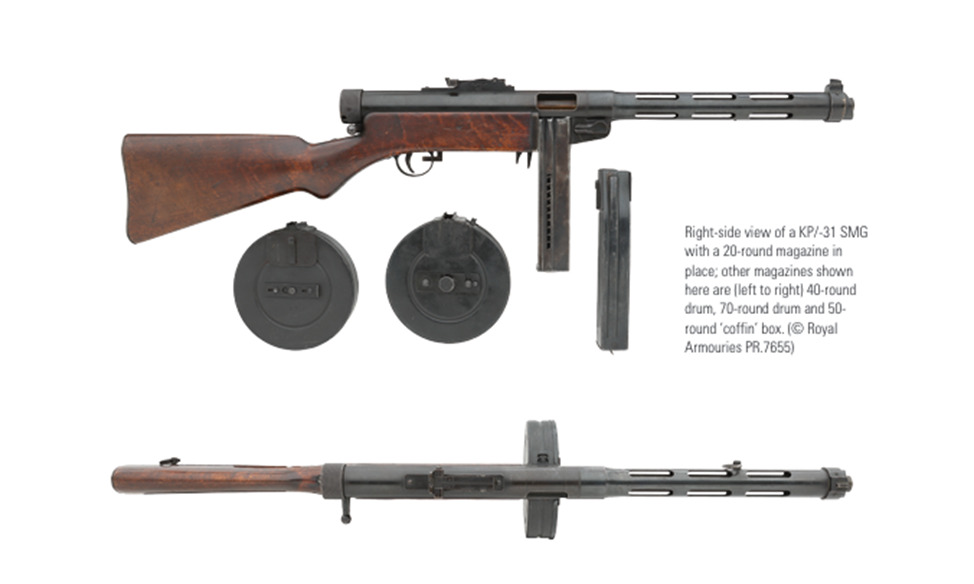

Suomi 20 box - 1br

Suomi 40 drum - 3 br

Suomi 50 box - 4br

Specifications:

Weight: 4.6 kg.

Length: 870 mm.

Barrel length: 314 mm.

Cartridge: 9 × 19 mm “Parabellum”.

Rate of fire: 900 rounds/min.

Muzzle velocity: 396 m/s.

Sighting range: 200 m.

Type of ammunition: box magazine for 50 rounds; drum magazine for 40.

Sight: non-adjustable, open, for 100 m, with a folding stand for 200 m.

Suomi M31 Specifications

The KP/ 31

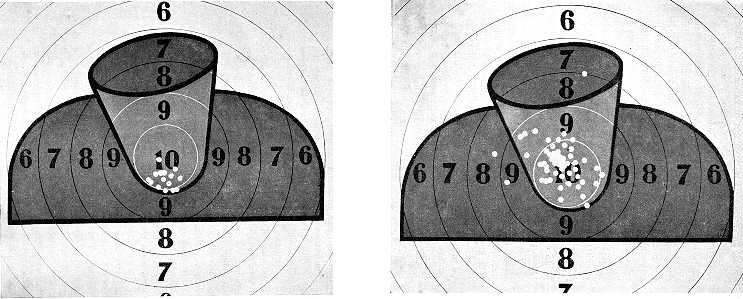

One problem with the KP/-26 was the curved magazine, which did not feed reliably. Lahti also felt the stock was not sturdy enough to withstand sustained combat usage. Some reliability problems had also manifested themselves as a result of the incorporation of some features of the Bergmann design. Reliability was enhanced significantly by a major change that saw the elimination of space in front of the bolt that often allowed a cartridge to turn and fail to feed; and by the use of a new 20 round box magazine and 40-round drum magazine designed to take the 9×19mm cartridge, for which Lahti chambered the updated KP/-26. Modification of the magazine well allowed the use of drum magazines as well as the Swedish ‘coffin’ magazine, while modifications to the barrel jacket made it simpler to produce and sturdier. A quick-release lever allowed the barrel to be changed quickly. As a rudimentary muzzle brake, the muzzle of the SMG was given a slanted cut. Other changes included an increase in cyclic rate from 750rd/min in the KP/-26 to 900rd/min in the KP/-31 and a reduction in overall length from 92.7cm to 87cm. Weight of the KP/-31 unloaded and loaded was greater than that of the KP/-26 – 4.6kg unloaded and 7.04kg loaded with a 71-round drum magazine for the KP/-31 versus 4.4kg unloaded and 5.04kg loaded for the KP/-26. The differential locking system of the KP/-31 is worth describing in some detail. The KP/-31 is a blowback, select-fire design. When the trigger was pulled, the firing pin, which protruded from the face of the bolt by about 1.25mm, impacted the primer, igniting the powder charge. At the point the firing pin impacted the primer, the bolt was not all the way forward, but the momentum of the bolt immobilized the cartridge case in the chamber until the chamber pressure was lowered enough for the remaining gas pressure to push the case out of the chamber, and the spent case pushed the breech bolt back against the recoil spring and the inertia created by the weight of the bolt. The bolt’s mass gained velocity to overcome the momentum pushing it backwards until it met the diaphragm of the receiver’s end cap, at which point the bolt went forward, chambering another cartridge; this process continued as long as the trigger was held back. Overall length of the KP/-31 was kept to a minimum by mounting the recoil spring within the bolt. These design changes had been tested by late 1930 or early 1931, but the Finnish Defence Ministry had still not placed any orders (Jaeger Platoon 2013). Things improved when Tikkakoski Rauta ja Puuteollisuusyhtiö (Tikkakoski Iron and Wood Industry Ltd) under the leadership of engineer Oscar Ostman purchased the rights to produce the

KP/-31 SMG. At this point the company had some experience producing rifle and machine-gun barrels for the Finnish armed forces; hence, Konepistooliosakeyhtiö ended its part in the story of the Suomi SMG (Jaeger Platoon 2013). Today, Tikki is still in business producing high-quality rifles in conjunction with Sako. (At one point, the Special Air Service used Tikki rifles for sniping.) The first time the designation ‘Suomi’ was used for the Lahti design was in a 1925 document. What is especially interesting about naming the SMG the ‘Suomi’ is that this is, in effect, calling the Lahti-designed SMG the ‘Finnish,’ the equivalent of calling the Thompson the ‘American’ or the Sten the ‘British’. In September 1930, an important early mention of the Suomi SMG was in the Hakkapeliitta magazine, the publication of the Soujeluskunta (the Civil Guards). A little over a year later, in October 1931, the Finnish Army placed an order for 100 of the new SMG in 9×19mm calibre. Its official designation was ‘9,00 konepistooli M/31’ (9mm submachine gun M/31). Although Tikkakoski offered various options, including a bipod, vertical foregrip and two types of selector switches, the Finnish Army ordered the most basic version (Heidler 2015: 11). Suomi SMGs required substantial machining to produce, as the receiver was machined from a solid Swedish chromium nickel steel forging. A tunnel for the breech bolt was bored, then honed, as was a narrower, concentric tunnel for the rebated neck of the bolt. Bolts were fabricated from the best Swedish steel, hardened to 55 Rockwell (Kekkonen; no date)

Magazines for weapons Suomi M31

The 70-round drum magazine was just one of the magazines developed for the KP/-31 during its years of service. This evolution is worthy of examination in some detail; and to understand how magazines work, some history is useful. Detachable magazines evolved from the charger clip, which fed cartridges into a fixed internal magazine. The US citizen James Paris Lee developed the detachable magazine for his Model 1879 rifle, though it is probably best known for use in the M1895 US Navy Lee rifle. Lee’s system was also incorporated into the British Lee-Metford and Lee-Enfield rifles. Basically, there are three primary types of detachable magazines: box, drum and pannier. The box magazine normally has cartridges placed parallel to the weapon’s bore in layers, either single row or double row. Pushing cartridges against a follower under spring tension allows the box magazine to be loaded. As the bolt of the weapon comes forward, it strips cartridges from between the magazine lips into the chamber. For automatic weapons, larger-capacity magazines are needed, which has resulted in many having a curved design. Single-row (single-stack) magazines have one cartridge atop another in a layer. Double-row magazines normally use a staggered-feed system with two rows of cartridges until they reach the feed lips, at which point they feed from alternate sides.

Single-row magazines normally proved more reliable in early machine guns, but this type of magazine needed length to have high capacity. In some machine-gun designs, such as the Madsen, a curved top-feed magazine was used, while in others such as the Johnson M1941 LMG, a side-feed magazine was used. As a result, the machine gun could fire from the prone position. For the MP 18/I SMG, Hugo Schmeisser invented a type of box magazine generally designated staggered-row-single-position feed. Using what came to be called ‘Schmeisser’s Cone’, cartridges rode in the magazine in staggered rows, but were forced into a single row prior to feeding into the chamber. Later, Oscar V. Payne invented a staggered-row, two-position feed magazine that caused two cartridges to converge alternately for smooth feed without need for a feed ramp, for the Thompson SMG. Of particular significance for the Suomi was the double-compartment magazine, with single feed, developed by the Swedish designer Carl Schildstroem and produced by AB Linde. This system was used in a four row, single-position feed magazine that held 50 rounds. In effect, this magazine contained two magazines feeding into Schmeisser’s Cone for single feed as the cartridges were chambered. This system was used in the Finnish ‘coffin’ magazine for the Suomi. Tikkakoski Oy purchased the rights to manufacture the ‘coffin’ magazine in 1940, and between 1941 and 1943 produced 120,000 of them. Magazine springs were still purchased from Sweden, however (Kekkonen; no date). Though this magazine was widely used in KP/-31 SMGs during the Winter War and Continuation War, Finnish troops found it heavy (0.91kg empty), complicated and unreliable. It was also very difficult to load fully, even with the special loading tool. Some claimed that without the tool, it was difficult to load more than ten rounds. (The author has, indeed, found the tool a necessity in loading ‘coffin’ magazines.) Finnish troops often loaded fewer than 50 rounds – sometimes as few as 25 – for reliability. Still, the 50-round magazine was lighter than the 71 round drum magazine, and its tapered springs allowed compression into a small space, keeping the overall length of the magazine only slightly longer than that of the 20-round box magazine. According to Pertti Kekkonen, the ‘coffin’ magazine was also too fragile, easily dented and quickly rendered unreliable if dust or dirt got inside (Kekkonen; no date). Given the operating conditions in Finnish forests, keeping debris out of the magazine could be problematical. Another solution to the problem of creating a high-capacity magazine for LMGs and SMGs was the drum magazine, which uses a spring to push cartridges in a helical path around the circular shape of the drum to feed one-by-one through the magazine lips. One of the best-known was the ‘Snail Drum’ developed for the German Artillery Luger and also used in the Bergmann MP 18/I. More influential for the development of the Suomi drum magazine were the 50- and 100-round examples developed for the Thompson SMG by Oscar V. Payne. These used a star-shaped cartridge pan combined with a multiple-arm follower moved by a clockwork spring. Consecutive cartridges were then fed into the lips of the magazine, which were cut into the drum’s side. The drum magazine used in the Suomi was designed by Oskar Alfred Ostmann of Tikkakoski Oy – but it should be noted that at least one source attributes the design of the 70-round magazine to Lieutenant Y. Koskinen, who developed it after the dissolution of Konepistooli Oy (Kekkonen; no date). Less complicated than the Thompson drum, Ostmann’s design had a single follower driven by a strong clockwork spring. This spring is often compared to that used on early Victor phonographs. A very strong spring was necessary to overcome the inertia of 70 rounds carried in the drum. When loading the 70-round drum, it is necessary to rotate the spring almost two full rotations clockwise. Cartridges are loaded standing on their bases – 35 into the inner groove fastened to a rotating feed plate and 35 into the outer feed groove. Cartridges feed first from the outer groove, then, when it is empty, they feed from the inner groove. Initially, the Finnish Ordnance Department ordered from Tikkakoski Oy 8,000 70-round drums on 28 January 1936, followed by orders for another 20,000 in April 1936 and 21,000 in January 1937 (Kekkonen; no date). The early Suomi magazines did not have the staying power of those discussed above. Initially, a 20-round magazine was developed; actually, it held 25 rounds, but was not reliable when fully loaded. A partially loaded magazine created a problem, however, if it were dropped, as a cartridge could rotate due to jarring so that the bullet ended up facing the rear of the magazine (Kekkonen; no date). These magazines had the advantage of being handy and light – only 0.44kg fully loaded. The 20/25 round box magazine was slow to load so production ceased prior to the Winter War. Once the war started, however, production resumed but was stopped again after the conflict ended. A 40-round drum was also used with early versions of the Suomi, but it proved unreliable and very difficult to load. If extreme care were not taken when loading, a cartridge could fall on its side, jamming the magazine and requiring all of the cartridges to be removed and the reloading process to start again. Although it proved virtually useless in the field, this magazine had a small round peephole through the bottom, and the magazine feed plate was marked ‘1’ to ‘40’, theoretically to allow the shooter to determine how many rounds had been fired. The 40-round magazine was nicknamed sissilipas, or ‘ranger magazine’ (Kekkonen; no date). Not only was the later 70-round magazine more reliable than the 40-round version, but it weighed the same fully loaded – 1.48kg – as the latter. Lahti also designed a 60-round drum using a sprocket-wheel mechanism similar to that used on Thompson SMG drums (Kekkonen; no date). This magazine was easier to load and was reliable, but it was not adopted. Presumably, Finnish production capacity was better served by continuing to produce designs for which tooling was already available. The number of magazines normally issued with the KP/-31 varied during the Winter War, but by 1943 was mostly standardized at either five 70-round drum magazines or seven 50-round box magazines (Jaeger Platoon 2013).

Suomi M31 at the Germans

Initially, the Finns who joined the German forces as part of the Volunteer Finnish SS Battalion took some Suomi SMGs with them. Later, Marshal Carl Gustav Mannerheim, commander-in-chief of Finland’s armed forces, visited Germany in June 1942, and donated an additional 120 KP/-31 SMGs, each with five drum magazines and 2,000 Finnish 9×19mm cartridges to the Germans. The remainder were given to an officer of 20. Gebirgs-Armee-Oberkommando on 11 July 1942. Markku Palokangas, an authority on Finnish weapons, also states that another 180 Suomi SMGs were in the possession of Divisionsgruppe Kräutler in northern Finland. On 12 March 1942, a licence was granted to supply Germany with 1,742 KP/-31 SMGs. This was followed with a licence for 1,100 more on 26 June 1942, and an additional 200 on 5 August 1943. In addition to the Suomi SMGs supplied to Germany mentioned above, some KP/-31s were also supplied to Croatia and Bulgaria, both of whom were fighting alongside the Germans.

Suomi M31 in other countries

Those Suomis that went to Germany have already been mentioned, as have the more than 5,000 that went to Bulgaria. Other export orders between August 1940 and November 1942 included 380 to Sweden, 32 to Denmark, 500 to Croatia (with another 750 ordered but likely not delivered) and 100 to Switzerland (another 5,000 were ordered but it is not clear how many were delivered). Those orders not fulfilled were the result of priority being given to production for the Finnish armed forces. For this same reason, an order for 5,000 Suomi SMGs from Romania during 1942 was not fulfilled (However, there is evidence that some of the orders were completed, and the Suomi M31 was delivered in limited quantities to Romania). A substantial number of Suomi SMGs were also manufactured under licence, with the most prolific producer being Sweden. Initially, at the Husqvarna factory, Sweden produced the kpist m/37, which was chambered for the 9×20mm Browning Long cartridge used in Swedish service handguns. Only a limited number were produced, however, as the Swedes soon switched to the 9×19mm cartridge. The model with the new chambering was designated the kpist m/37-39. There were some distinct differences between the Finnish KP/-31 and the Swedish kpist m/37-39. These included a different stock, a shorter barrel and barrel jacket, and simpler sights. The kpist m/37-39 was produced from 1939 until the mid 1940s. It was primarily used with the 50-round ‘coffin’ magazines, though later it was used with the 36-round box magazines for the Carl Gustav m/45 SMG. Sweden exported the kpist m/37-39 to Norway, Denmark, Indonesia and Egypt. The Swedes also had what was designated the kpist m/37-39F, a designation applied to the KP/-31 SMGs that had been imported from Finland. During World War II, Denmark also produced the Suomi as the m/41 for the Danish Army. The primary differences from the Finnish KP/-31 were in the stock and the front sight, which had protective ‘ears’ on each side. About 1,400 m/41 SMGs had been produced before the Germans completely disarmed the Danish Army and seized the m/41s. At least some were later issued to Danish collaborators. The Swiss used a substantial number of Suomi SMGs. Those Tikkakoski-made KP/-31s they had imported from Finland were without the muzzle brake and were designated the MP 43 in Swiss service. As part of their November 1942 contract with Finland, the Swiss had also obtained a licence to produce the Suomi in Switzerland. Production was carried out by Hispano-Suiza, with an estimated 22,500 SMGs delivered. These weapons were designated the MP 43/44. They were very similar to the Finnish KP/-31 except for the rear sight, which was of ‘L’ type with settings for 100m and 200m. Among the more interesting users of the MP 43/44 were the Pontifical Swiss Guards, who used them from World War II until they were replaced by the Heckler & Koch MP5 in the 1970s.

Information taken from the book: