In the final years of World War II, Germany faced significant industrial, logistical, and resource constraints. To address this, arms manufacturers began developing simpler, cheaper versions of existing weapons. Steyr-Daimler-Puch, the manufacturer of the MP 40 in Austria, created an experimental version of this submachine gun with the aim of improving performance and facilitating mass production.

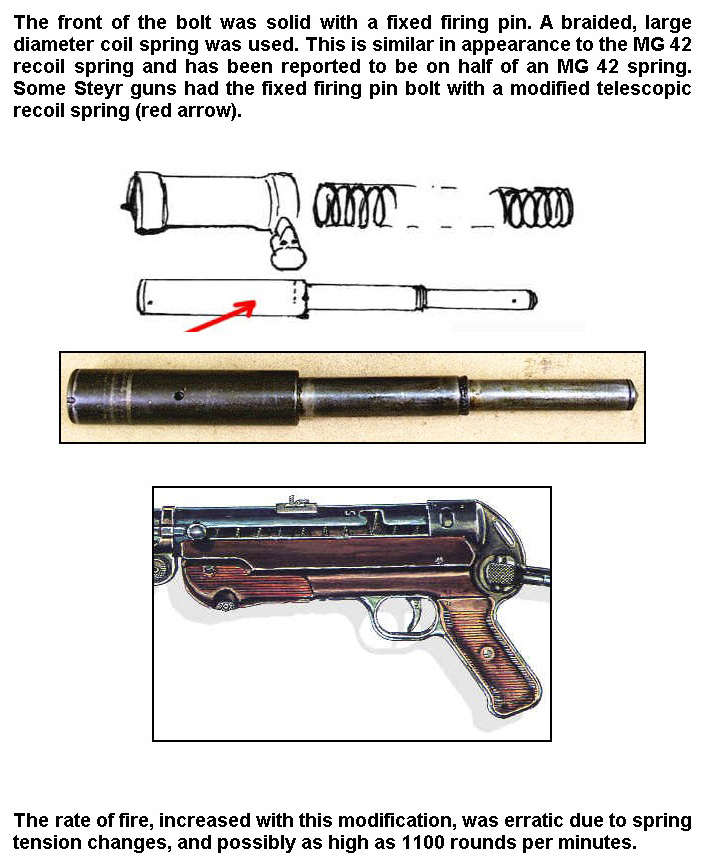

This experimental version of the MP 40 featured two significant changes compared to the standard model: the replacement of the conventional firing pin with a fixed firing pin (integrated into the bolt) and the introduction of a telescopic recoil spring, inspired by that used in the MG 42 submachine gun. The purpose of these modifications was to reduce the number of moving parts, simplify the weapon’s internal functioning, and allow for a higher rate of fire.

The weapon still used the 9×19mm Parabellum caliber, firing from an open bolt with a simple blowback operation. The feed rate remained the same as the original MP 40, with a 32-round magazine. Although the weapon’s external structure was nearly identical to the standard version, the interior was significantly modified to incorporate these improvements.

Thanks to the adoption of a fixed firing pin and telescopic spring, this variant had a higher rate of fire, estimated at 1,100 rounds per minute—significantly higher than the 500–550 of the standard MP 40. The weapon was considered simpler and lighter, ideal for arming territorial defense forces or militias like the Volkssturm. However, it never entered mass production.

This was likely due to a combination of factors: the imminent end of the war, the growing logistical difficulties of German industry, and the focus on developing more advanced weapons, such as the StG 44 assault rifle. Furthermore, simplified weapons like the MP 3008 were already in more advanced production, at lower costs and even greater complexity.