Experienced rifles of Goryainov and Mamontov (USSR. 1936 year)

April 2 201411

While working at TsKIB SOO, I had a chance to hear from Yu. P. Platonov, the head of the theoretical department and one of the veterans of the organization, history. Somewhere in the middle of 1990-ies, I. Ya. Stechkin, conducting tests of the silent revolver OTs-38, ran into an unusual effect. After the next shot, it was suddenly discovered that the trigger of the revolver had bounced back and stood on a combat platoon! There could be no question of chance - the effect was repeated regularly and prevented debugging. weapons. In fact, the OTs-38, like any other classic revolver, does not have a uncoupling mechanism, and when the trigger is pressed, you cannot trigger the trigger on a combat platoon. But, apparently, after the shot from the concussion, the trigger turned a little towards the initial position and his whisper caught the trigger. There is nothing unusual in this phenomenon - a similar effect is used in the USM with the so-called. “Disrupting whispered.” The unusual fact of a strong rebound of the trigger was unusual, as there are no mechanisms for cocking it without the participation of the shooter in the OC-38. At a time when Igor Yakovlevich was thinking about how to deal with a problem, Yu. P. Platonov approached him and unwittingly became involved in its solution. The thinking of gunsmiths was about the following. The force that threw the trigger back could only affect his striker. But where does it come from?

Perhaps, it is a cartridge primer, moving back under the action of pressure of powder gases arising from the shot, pushes the striker? Similar schemes of automation are well known (the so-called Rota system). But in them, as a rule, special cartridges were used with an enlarged stroke of the primer in the socket. And in conventional cartridges the shift of the capsule is very small - in 7,62-mm rifle cartridges 0,25 – 0,38 mm. In the cartridge SP-4, used in the OTs-38 revolver, the magnitude of the shift of the cap is even less, because it has a reinforced mount in the socket, and it is not enough to overcome the pressure of the mainspring. The only explanation for the effect was that the entire sleeve was displaced. After all, there is a gap allowing the sleeve to “pass” back between its bottom and the frame of a revolver, which is necessary for the free rotation of the drum. Additional experiments confirmed the validity of this assumption. I. Ya. Stechkin had to introduce into the design of OTs-38 the mechanism of the anti-rebound trigger. The effect described above cannot but cause the designer-gunsmith to use it as an energy source for actuating the moving parts of the weapon, i.e. engine automation. This engine looks tempting, it allows you to radically simplify the design of weapons, reduce size and reduce weight. Hasn’t anybody ever thought of such an obvious and beautiful solution? Further study of the topic showed - it came, and more than once …

In the collection of weapons from the technical office of the TsKIB SOO I had a chance to see experimental self-loading rifles of the Goryainov design and the Mamontov design (two variants) that did not have external signs of the automation engine - they had neither vapor devices nor a mobile barrel. And now, intrigued by the story of Yu. P. Platonov, I again went to the technical office and began to “torment” these rifles - something told me that without the “OT-38 effect” there was no cost. And for sure - the inspection of the rifles showed that their automation worked by shifting the cartridge case in the chamber during the shot.

Both rifles are “mock” samples, i.e. experimental platforms designed to explore the possibilities of the new principle of automation. Rifle Goryainova dated 1936 year. I managed to find out some information about the designer of this rifle. Makar Fedorovich Goryainov graduated from the Leningrad Infantry School in 1926 and completed a number of posts from a platoon commander to a division commander. After graduating from the Military Technical Academy im.F. E. Dzerzhinsky served in the Main Directorate of the Military Industry, in 1936 he fought in Spain. In 1940, the city of Goryainov served in the Moscow weapons-technical school of the NKVD and was actively engaged in scientific activities. 1944 to 1946 Major General M. F. Goryainov supervised this school, then worked in the management of universities of the USSR Ministry of Internal Affairs.

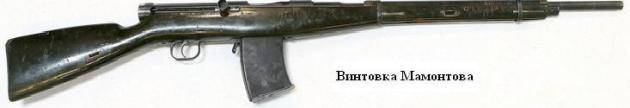

Mamontov’s rifle was developed in 1936. It used parts of serial rifles: barrel from rifle, model 1891, shop from ABC-36. USM shock type with a “rear” sear. There are Revelly grooves in the chamber that facilitate the extraction of the liner and reduce the likelihood of its transverse rupture. 3,7 rifle weight kg. The rifle designer Mikhail Alekseevich Mamontov (6.11.1906 - 18.07.1993) is well known in Tula’s weapon circles, primarily as the founder of the Tula scientific weapons school. A graduate of the Military Mechanical Institute 1931, in 1931-1937, he worked at the Tula PKB (TsKB-14) in positions from design engineer to chief engineer-deputy head of the PKB. In 1937, M.A. Mamontov was appointed head of the newly formed department “Designing Automatic Weapons” of the Tula Polytechnic Institute, where he worked for almost 56 years, becoming a doctor of technical sciences, professor, author of numerous works on the theory and calculation of gas-dynamic devices of small arms. On the device mechanisms automatic rifles should stay in detail. They are based on a general principle - the leading link (slide frame) is actuated by the bottom of the liner that moves in the chamber during a shot within the mirror gap. In principle, such a system does not differ from a conventional side exhaust gas engine, except that the sleeve itself plays the role of a piston in it. In both rifles, the coupling of the bolt with the receiver is carried out by a transversely sliding wedge, but the design of the mechanisms that activate the wedge is different. In the Goryainov rifle, the movement of the liner is transmitted to the bolt carrier through a structurally integrated pusher passing through a channel in the bolt body. On the sides of the frame there are beveled grooves, which include the projections of the wedge. When locked, the wedge moves down. The stroke of the bolt carrier under the action of the liner is very small - only 0,3 mm, then it moves by inertia around 3 mm. During this time, the bullet manages to leave the barrel bore, after which the frame joins the wedge and lifts it, carrying out unlocking. In the Mammoth rifle, the locking wedge is actuated by two projections on a massive drummer, which is actually a bolt carrier. The movement of the liner is transmitted to the impactor through a sleeve worn on its front end, the front end of which is the bottom of the gate cup. When the moving parts reach the extreme front position, the body of the bolt stops, and the drummer, continuing to move forward, pushes the locking wedge to the left into the channel of the receiver, making the locking. At the end of his turn, the drummer shifts the sleeve forward, presses it to the sleeve and punctures the cap - a shot occurs. When fired, the sleeve moves backwards and pushes the sleeve, which, having passed through the 0,5 mm sleeve, pushes the drummer back, and, by the inertia of 19 mm, pushes the wedge out of the box groove, unlocking the barrel bore.

In both rifles the shift of the liner actuates only the locking mechanism, and the main part of the energy for carrying out the reloading cycle is obtained by moving parts due to the action of the residual pressure in the barrel to the bottom of the liner. Thus, a sleeve engine, in the form in which it is implemented in Goryainov and Mamontov rifles, is not in the full sense an automation engine. Its design is aimed at unlocking the bore at the moment when the pressure in it falls to a value at which it can be used to actuate the moving parts without the danger of a transverse breakage of the liner. According to the existing classification, such weapons belong to mixed-type systems (different principles of operation are used for unlocking and reloading), although with some refinement the sleeve principle can be made a full-fledged automatics engine. Documentary evidence of the results of testing rifles could not be found, but, judging by the fact that this topic did not receive development, it can be argued that the described principle of automation did not justify the hopes of the designers and they stopped working on it.

The current level of knowledge about the dynamics of automatic weapons allows you to accurately determine the cause. First of all, the sleeve motor had insufficient power that did not allow the locking mechanism to receive enough energy to function in the entire range of operating conditions. The operating cycle of the engine occurs in a very short period of time - the bottom of the liner selects the mirror clearance for a time of about one thousandth of a second, even before the maximum pressure in the barrel is reached. For comparison: the side exhaust gas engine of a SVD rifle operates for about 0,005 s, i.e. 5 times longer. As is known, the magnitude of the impulse of force applied to the body (in this case, to the slide frame from the liner side) is directly proportional to the time during which this force acts. Thus, the liner engine is potentially significantly weaker than the classic lateral gas exhaust. It is almost impossible to increase the engine power by extending the time of its operation by increasing the displacement of the liner - beyond the critical value of the mirror clearance (for a rifle cartridge near

0,45 mm) transverse breakage occurs. And it will not be possible to completely eliminate it even due to the introduction of Revelly’s grooves in the chamber, which was proved by the experience of operating the SVT rifle. In principle, it is possible to increase the stock of energy of the slide frame, increasing its weight. But then it becomes possible to delay the actuation of the unlocking mechanism, in which the residual pressure in the bore will not be enough to actuate the moving parts.

In this case, the inertia of the frame can be used, but this will lead to an increase in the size and weight of the weapon and the loss of the advantages for which such an engine was created … In addition, the extremely sharp nature of the engine and the associated impacts of the locking mechanism cannot be eliminated their overload and breakage. And most importantly - the sleeve engine has an almost fatal disadvantage in the form of unstable operation, depending on a number of parameters of weapons and ammunition. For example, the stroke of the bolt carrier under the action of the liner, and, consequently, engine power, depends on the size of the mirror clearance, which, in turn, depends on the tolerance on the dimensions of the liner (for a rifle cartridge, on the thickness of the flange). This parameter varies in a certain tolerance - for a rifle cartridge up to 0,13 mm, i.e. on 8%. The engine parameters are very sensitive to the extraction force, and, accordingly, to the manufacturing accuracy and condition of the chamber surface and sleeves, barrel temperature, the presence of lubricant on the friction surfaces of parts and other factors, many of which vary from shot to shot. And all this without the influence of difficult operating conditions (dust, grease, etc.)! In general, in the described form, the cartridge engine can ensure the operation of the weapon’s automation only in “room” conditions.

The mammoths and Goryainovs were not the only gunsmiths who were attracted by the merits of the automatics sleeve motor. Similar, in fact, the engine, which only worked due to the impact of the primer on the drummer, was developed in 1935 by F.V. Tokarev (“Kalashnikov” №7 / 2011 g.). But the overall result of the work of all the designers turned out to be the same - the development of the topic stopped, and the samples themselves were “buried” in museums. This suggests adding “… and the idea is forgotten forever.” As it turned out - not forever. It is difficult to say whether the designer A.F. Baryshev was familiar with the works of Mamontov, Goryainov and Tokarev (most likely not), but the automation system developed by him at the beginning of 1960-s, implemented in the range of samples of caliber from 5,45 to 30 mm and positioned as “unparalleled,” he built on the same principle. This happens quite often - people working on the same problem, with similar restrictions, come to similar technical solutions independently of each other. At the same time, it should be recognized that Baryshev managed to create a largely original and perfect system in which the sleeve engine is a full-fledged engine of automation.