Heavy machine gun R. Robinson (Australia)

February 24 20167

Large caliber small weapons always associated with a corresponding powerful impact. For stories The development of armaments has repeatedly made various attempts to reduce the force of recoil and thereby simplify the use of weapons. Some of these attempts failed, while others ended in success. One example of a recent exodus was a family of projects developed by Australian military engineer Russell Shepherd Robinson. In the early forties of the last century, he proposed the original design of a large-caliber machine gun, characterized by its small size and low recoil.

Path to machine gun

Russell S. Robinson was born in 1911 in New Zealand, but then changed his place of residence several times. The Robinson family moved first to Australia and then to the United States. There Russell entered the Massachusetts Institute of Technology, from which he graduated in 1932 with a diploma in aircraft engineering. Later, the young specialist participated in several aviation projects, and in addition, he built an aircraft of his own design. In 1933-35 R. Robinson took part in the Antarctic expedition of Admiral Richard Evelyn Byrd, after which he decided to return to his homeland. By the end of the decade, Robinson had already moved to the UK, enlisted in one of the aviation companies, and then went to Australia.

Until a certain time R. Robinson participated only in the projects of the aviation industry. However, some assignments were of particular importance. So, in the late thirties, he was included in the special commission and sent to Germany. The task of Robinson and colleagues was to visit German aircraft factories and thoroughly examine the samples of equipment demonstrated by them. Thus, under the guise of “a specialist in nose strut chassis,” R. Robinson visited German factories, evaluated equipment, and then passed the information to the leadership of the British Air Force and industry.

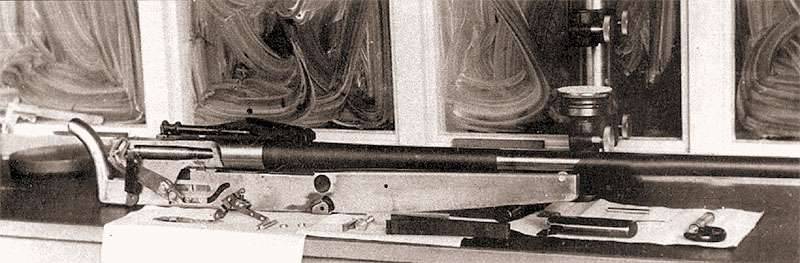

Machine gun SR Model 2 assembly

In 1939, Robinson was transferred to Australia, where he had the opportunity to take part in the modernization of existing aircraft. Over the next couple of years, the engineer engaged in enhancing the characteristics of various techniques, and also participated in the creation of new specialized aircraft. Finally, in 1941, R. Robinson became a personnel officer of the Australian Air Force, and soon he was assigned to develop an updated weapon system for fighter planes. Thus began his career as a gunsmith designer.

At the initial stage of the war with Japan, the Australian pilots had to face the new A6M Zero fighter created by the Mitsubishi company. At that time, Australian fighters were armed only with machine guns, while Japanese vehicles already carried 20-mm automatic cannons. Such an advantage in caliber posed a particular danger to Australian aviation, because of which there was a proposal to modernize the existing equipment. Calculations showed that the old British-made fighters in service could not carry small-caliber artillery, but in theory they were capable of using large-caliber machine guns.

12,7-mm machine guns could give the necessary increase in firepower, but hardly fit into the existing compartments. In addition, there was a problem in the form of unacceptably high recoil, which the fighter design could hardly withstand. Some kind of new weapon with high fighting qualities and small dimensions, as well as with reduced recoil, was required.

Russell S. Robinson, already involved in the modernization of Australian aircraft, decided to join the solution to the problem of armament. At the same time, he proposed to apply the idea that emerged from him while he was studying at the institute. The concept developed by him at that time was called Constant Reaction Principle (“The principle of constant reaction” or “Weapons with a constant force of impact on the support”) and made it possible to significantly reduce the recoil force.

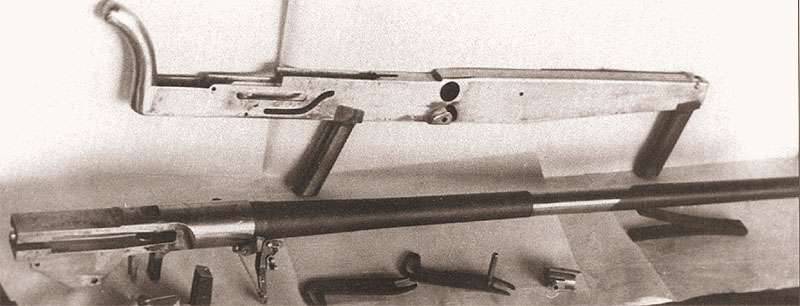

Incomplete disassembly of the machine gun Model 2

The first months of 1942, the designer spent on the elaboration of the preliminary draft and the preparation of relevant documentation. 11 in May of the same year R. Robinson presented the drawings to the Army Invention Directorate (Army Invention Directorate or AID). Military specialists became interested in the proposal and allowed Robinson to continue developing the project with the subsequent production of a prototype, now in the interests of the army. Nevertheless, it was necessary to design and assemble weapons in their spare time. In this case, the engineer could bring to work several hired assistants. The new project received the symbol Model 2 or SR Model 2 (Shepherd Robinson Model 2).

SR Model 2

The constraints that the gunsmith encountered at an early stage of work led to a host of technical and technological problems. Not having access to normal materials, R. Robinson and his colleagues had to use not quite suitable components, which further affected the characteristics of the weapon. In particular, some parts had a greater resource than others. Later, the designer recalled that the project of a large-caliber machine gun had one curious feature. The first experienced semi-hand-made machine gun during the tests and refinement never worked correctly, but showed itself perfectly during demonstrations to the customer.

The perspective large-caliber machine gun Model 2 had a rather simple construction, however in it some new ideas were realized. Due to the impossibility of production from scratch, some parts were borrowed from existing systems. In particular, the 12,7 mm rifled barrel was borrowed from the Browning M2 serial machine gun and shortened to the required size. Most of the other parts were made specifically for the Model 2 prototype.

The main element of the new weapon was a rectangular receiver, resembling a box. It had the shape of a gutter without a lid. The main parts were fixed on its upper part, and holes and grooves were provided on the side surfaces for mounting various parts. In the front wall of the box were provided mounting for the installation of a rolling barrel. The breech and middle parts of the trunk could additionally be closed with a cone-shaped casing. On the breech, the top of the receiver, there were devices for contact with the gate. Also the barrel and bolt group were in contact with the return spring.

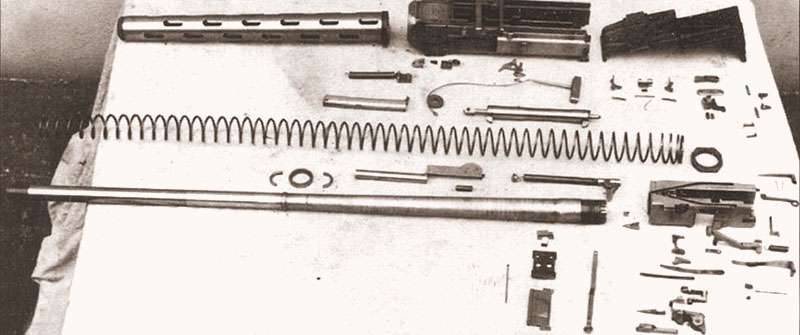

Full disassembly Model 5

In the back of the receiver located trigger mechanism, borrowed from the machine gun M2. Also on the receiver had two handles for holding and shoulder rest. The ergonomics of the weapon was developed taking into account the design characteristics of the original automation “with a constant force of influence on the support.” The preliminary draft claimed that the recoil force of the SR Model 2 heavy machine gun would not differ from existing rifles.

The original idea of R. Robinson implied the use of several non-standard stores, which made it possible to significantly reduce the return parameters. It was assumed that the design of the weapon will not have any parts, the movement of which will stop with a sharp blow. In this way, it was planned to exclude the presence of sharp impulses that affect the stability of the gun and transmitted to its installation systems. Calculations of Robinson showed that the use of automation “with a constant force of impact on the support” will reduce the size of the weapon, as well as reduce its impact. With the successful implementation of all ideas, the possibility of creating a unique small arms.

Opportunities to reduce the size of the weapon were implemented in the first draft Model 2. The total weight of the machine gun without ammunition was 8,2 kg, of which 4,1 kg accounted for the barrel length 914 mm. Available dimensions and weight allowed to shoot a new machine gun without relying on the machine or bipod. For shooting with arms provided handles and shoulder rest. Unlike other weapons of the family, the first prototype had to use a box magazine for 9 cartridges. In the future, it was planned to transfer the machine gun to tape power.

The assembly of the first prototype was completed in the autumn of the year 1942. Weapons tested at the site and finalized with a view to some increase in reliability. October 6 working prototype of the SR Model 2 was first shown to the military. During the demonstration firing, the low reliability of the experimental store was noted: it allowed no more than 5-6 shots to be fired without delay. Despite this, the testers successfully fired with firing within the capabilities of the store. In this case, the shooting was carried out with an emphasis on the shoulder. The new machine gun used a large-caliber 12,7x99 mm (.50 BMG) cartridge, but its return was at the level of a Lee-Enfield rifle.

Shooting from a Model 14 machine gun in an infantry version

According to the results of the demonstration of an experienced machine gun of the first version, the military delivered their verdict. Warlords ordered to continue the development of the project. At the same time R. Robinson had the opportunity to engage in a new large-caliber machine gun during his working time. In addition, the designer registered a new firm, Shepherd Robinson Arms Development, which soon received an order to continue the work. At the beginning of 1943, Munitions Annex was recruited to manufacture and supply the necessary components to the project.

SR Model 5

The new project of a large-caliber machine gun based on the Constant Reaction Principle was developed on the basis of the “Model 2”, but it had to differ in the mass of details. One of the main innovations of the project was the use of a full-fledged “machine-gun” tape feed. In the design of weapons involved only three people: Robinson himself and two assistants. It took only 15 weeks to create a new project.

Such a rapid development of new weapons by only three people was made possible thanks to the original approach to design. The main work fell on the chief designer, who became R.Sh. Robinson. Working without breaks and weekends, he shaped the look of various parts, looked for their optimal configuration and made a lot of sketches. Next, the draftsmen were taken for the design of the necessary design documentation, and the project manager began to deal with new nodes. During the preliminary study of the details, technical drawings were made without respecting the scale and other “formalities”. This approach made it possible to immediately verify the correctness of the proposed idea and identify its shortcomings. Only after the check, were complete drawings of parts and assemblies performed. In view of the appearance of a mass of unwanted drawing paper with discarded sketches, the duties of one of the assistants draftsmen included checking the relevance of the papers and disposing of unnecessary ones.

The complete set of 130 drawings was ready by June 1943 of the year and handed over to Munitions Annex. A few months spent on the production of a prototype. He was transferred to the tests only in October.

For ease of manufacture and use, the Model 5 machine gun was divided into several main units: a receiver with a barrel cover, a barrel breech sleeve, a reciprocating-buffer mechanism, a slide group, trigger, and an ammunition supply mechanism. Within the framework of the new project, existing ideas were used, but now several new nodes have been developed, and the old ones have undergone a most serious refinement. As a result, the new machine gun retained the general principles of operation, but was distinguished by specific moments of their implementation.

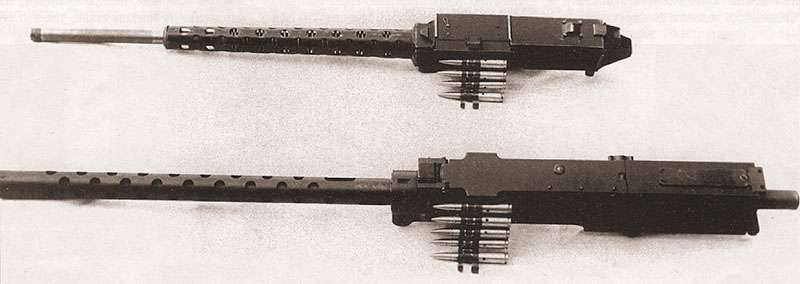

Aviation Model 14 (top) versus Browning M2

In full accordance with the original idea, the SR Model 5 machine gun received a movable barrel connected to a return spring. During firing, the barrel and the massive bolt had to move in different directions, ensuring that all necessary operations were carried out. In preparation for firing, the bolt and barrel were retracted to the rear position (with a gap between them) and recorded in a sear. When the trigger was pressed, the bolt and barrel began to move forward. The shutter was supposed to apply to the chamber of the cartridge. The shot was made before the barrel finally squeezed the spring and held the most forward position. Under the impact of recoil from the shot, the barrel, not reaching the extreme position, braked and began to move backwards. At the same time, the shutter was unlocked and the liner was extracted. Not reaching the extreme rear position, the bolt and barrel under the action of the return spring had to retard and move forward again, producing a new shot.

Thus, during firing, the barrel and bolt had to move back and forth without hitting any details of the weapon in their extreme positions. This design required a special calculation, but provided more than remarkable recoil characteristics.

Machine gun “Model 5” received a tape power system mounted on the receiver cover. Ribbon feed with .50 BMG cartridges could be carried out on both sides. Cartridges were thrown down.

The SR Model 5 without ammunition weighed 14 kg, the weight of the barrel was 4,5 kg. As you can see, the creation of a full-fledged receiver and other mechanisms, including a system for feeding cartridges, significantly affected the mass of the structure. At the same time, the weapon had the smallest possible dimensions, allowing it to be used not only as infantry weapons, but also for equipping various vehicles. Thus, the rear part of the receiver (from the bottom of the sleeve in the tape to the wall of the box) had a total length of 146 mm - less than that of rifle-caliber machine guns. However, at the price of small dimensions was a dense arrangement of units, which can complicate maintenance.

Infantry SR Model 14 on the machine of American development

The tests of the experienced ribbon-powered machine gun began in mid-autumn 1943. The first shooting ended in failure. There were problems with the ammunition system and some other nodes. It took almost half a year to correct the identified deficiencies. In the spring of 1944, a new contract was signed with another contractor that was responsible for producing the necessary parts. Attracting a new plant allowed us to speed up the assembly of an improved prototype machine gun.

During the full test, the Model 5 machine gun showed a rate of fire at the level of 650 rounds per minute. The design and small dimensions of weapons received high marks from the military. During the tests at the landfill machine gun installed on a special machine and measured the recoil force. Thanks to the original automatics, the Robinson machine gun recoil was only 15% of the corresponding parameter of the M2 product. In terms of dimensions, the machine gun did not differ from rifle caliber systems, which made it possible to use it for armament of various vehicles.

During the tests, the high characteristics of the weapon were confirmed, and also some flaws that required improvements were identified. So, it turned out that the widespread use of springs was not justified. Most of the weapons mechanisms later received other drives. This made it possible to improve the synchronization of the work of various units and increase the reliability of the weapon.

SR Model 14

The Royal Australian Air Force, having familiarized themselves with the test results of the Model 5 machine gun, showed great interest. In this regard, there was a technical task for the development of a new machine gun, which was planned to be put into service. In accordance with this document, the new machine gun R.Sh. Robinson should have firing characteristics no worse than the American large-caliber Browning. At the same time, the recoil should have remained at the level of the M1919 machine gun, and the dimensions of the units remaining inside the combat compartment of the armored vehicle, at the level of Vickers. The use of non-standard materials or technologies was not allowed.

Russell S. Robinson firing from a Model 14 demonstration machine gun

The next project of the large-caliber machine gun was designated SR Model 14. Within the framework of this project it was planned to develop two versions of weapons, for aviation and for ground forces. From the point of view of construction, the “Model 14” was a further development of the previous sample with the elimination of the main drawbacks. Thus, the correct operation of the power supply systems was ensured and the extra springs removed. In addition, some ergonomic and other improvements were applied. When developing a new project, an already proven approach was used, in which one designer solved all the main tasks, and two draftsmen helped him in various issues. This allowed the development of two versions of the machine gun by November 1944.

The infantry version of the machine gun could use two barrels with the possibility of quick replacement. Both had a length of 914 mm and differed mass, affecting the rate of fire. So, for shooting with a rate of 350 rounds per minute, a heavy barrel weighing 13,6 kg was proposed. The second barrel weighed 10,4 kg, allowing you to shoot up to 450 per minute. The maximum weight of such weapons (without ammunition) did not exceed 21,8 kg.

The aircraft machine gun was equipped with a lightweight 4,5 kg barrel, which allowed firing at a rate of up to 650-700 shots per minute. The possibility of replacing the trunk is not provided. Aircraft modification of the SR Model 14 differed less weight - 15,4 kg without cartridges and ribbons.

For use in demonstration shooting on the basis of an aviation machine gun a special sample was assembled. A special supporting structure with a pair of handles and a trigger hook, remotely connected to the trigger of a machine gun, was fastened under its barrel. Also on this weapon was provided shoulder rest. Shoot from this demonstrator offered standing, with a weapon on his shoulder. Probably, R. Robinson believed that shooting from a large-caliber machine gun in bursts from the shoulder would make a great impression on the audience, including from the military department. In addition to the prototype demonstrator, several more machine guns were manufactured in aviation and infantry.

Shooting from a demonstration machine gun

In January, 1945, R. Robinson went to the UK to promote his development. Within a few weeks, British enterprises produced parts for six machine guns, which were planned to be used in tests. After that, Robinson returned to Australia and continued working at home. Soon he again had to go to England, where he, among other things, was engaged in the refinement of the bolt group. One of the goals of these improvements was to bring the rate of fire of the aviation machine gun to 1000 rounds per minute.

Until the end of 1945, Australian enterprises produced a batch of 12 Model 14 machine guns in an infantry version. Another six aircraft machine guns were assembled by the British industry. More this weapon was not made.

Due to the end of World War II, the interest of the Australian and British military to the promising large-caliber machine gun fell. The rate of work decreased, and then they froze at all. New tasks were on the agenda, the solution of which did not allow to fully engage in the development of new small arms. As a result, many original designs were suspended or closed. The sad list includes the development of Russell Shepherd Robinson. His machine gun, the SR Model 14, no longer interested the customer.

In the form of the machine gun that existed at that time, the Model 14 needed some modifications. Later, the designer noted that in order to provide the required characteristics, it was necessary to resort to borrowing parts. So, the reloading mechanism could be much easier if the Robinson team used the necessary parts from the Browning machine gun. There was no opportunity to make such adjustments, since the customer was no longer interested in continuing the work.

In the late forties, not seeing the real prospects of their development, R.Sh. Robinson left military service and left for the United States. Practices on the original submachine guns and large-caliber machine guns with reduced recoil rates did not interest anyone and were virtually wasted. The Australian Army continued to use existing weapons.